T3 p – Metal Sales T6-A User Manual

Page 2

PEF-2

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Office) • www.metalsales.us.com

E

xposEd

F

astEnEd

p

anEl

s

EriEs

T3 P

anel

o

verview

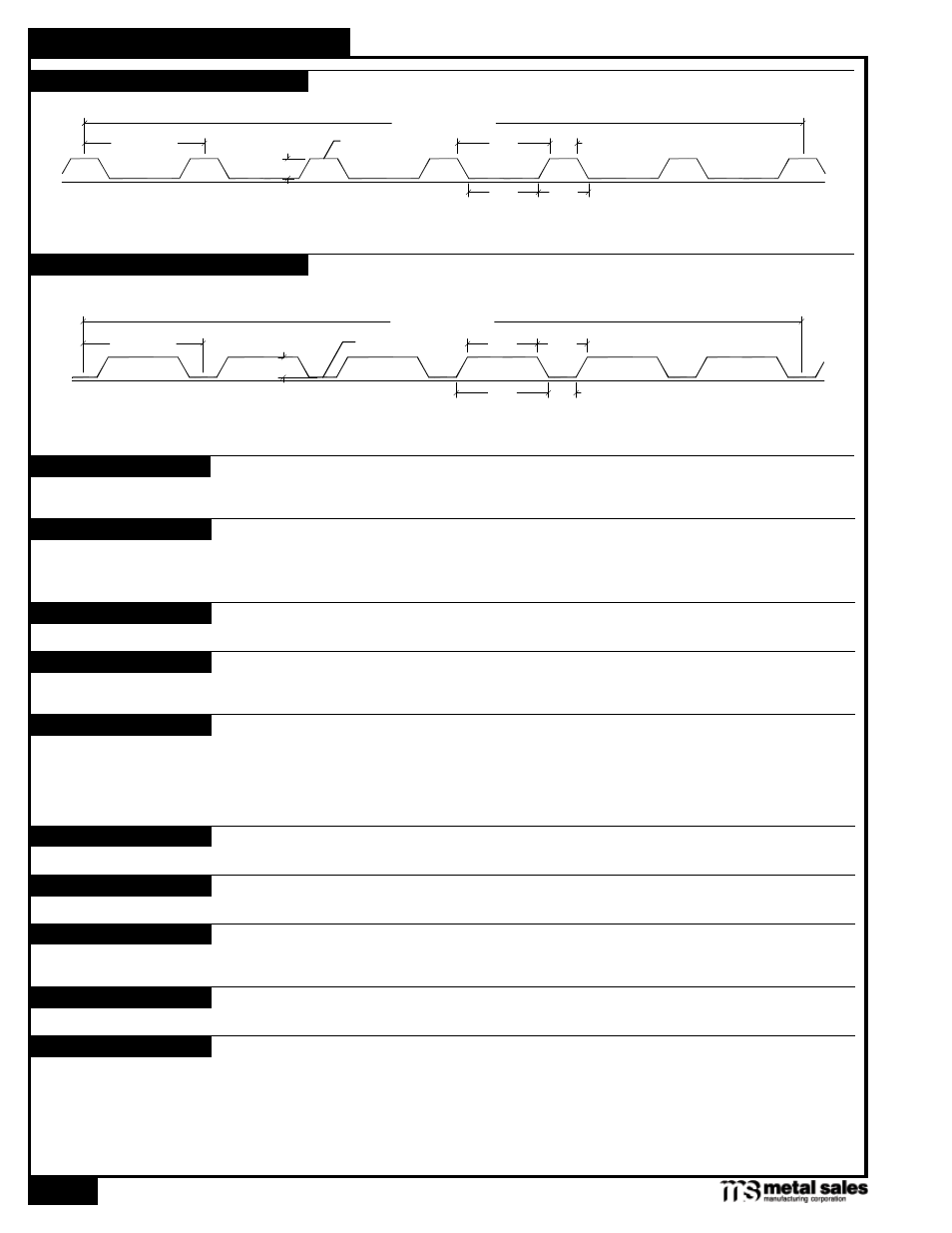

T3 ROOF PANEL PROFILE

T3 WALL PANEL PROFILE

C

36" Coverage

1"

6" Pitch

4

5

/

8

"

1

3

/

8

"

3

1

/

2

"

2

1

/

2

"

C

36" Coverage

1"

6" Pitch

4

5

/

8

"

1

3

/

8

"

3

1

/

2

"

2

1

/

2

"

SUBSTRATE

COVERAGE

LENGTH

AVAILABILITY

APPLICATION

FASTENING SYSTEM

FASTENERS

MATERIALS

FINISH

T3 panel is designed to be utilized over open structural framing, but can easily be used with a solid substrate.

The recommended substrate is

5

/

8

" plywood with a 30 pound felt moisture barrier. To avoid panel distortion, use

a properly aligned and uniform substructure.

Each panel has a coverage of 36".

Lengths under 5'-0" are available with some cutting restrictions. Please consult your Metal Sales branch for

maximum panel lengths and recommendations (see PGI-2 and PGI-3 for locations).

Panels are available in 24 through 16 gauge. Minimum quantities may apply.

Custom capabilities include:

-Crimp curving on numerous panel profiles.

-Curving may be convex, concave, or "S" curves.

-Perforated panels for wind screens and liner panels.

Commercial, Industrial panels.

Direct Fastened (exposed).

The fastener selection guide should be consulted for choosing proper fasteners for specific applications.

Quantity and type of fastener must meet necessary loading and code requirements (see PGI-12-14).

Steel grade 50, per ASTM A-792. Optional material: stainless steel, copper, and aluminum.

*

Acrylic Coated Galvalume

®

(ACG) / ASTM A-792 - AZ55

Multi-Pass Kynar

Prepainted Galvalume / ASTM A-792 - AZ50

Marbilique

MS Colorfast45

®

Plastisol

**

Fluorocarbon (PVDF)

Polyester

*

Differential appearance of Acrylic Coated Galvalume roofing materials is not a cause for rejection.

**

Meets both Kynar 500 and Hylar 5000 specifications.

SLOPE

The minimum recommended slope for any T3 panel is 1:12. Metal Sales recommends that in all roof applica-

tions, sealant be used on sidelaps.