Metal Sales T6-A User Manual

Page 11

PEF-11

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Office) • www.metalsales.us.com

E

xposEd

F

astEnEd

p

anEl

s

EriEs

d

esign

/ i

nsTallaTion

C

onsideraTions

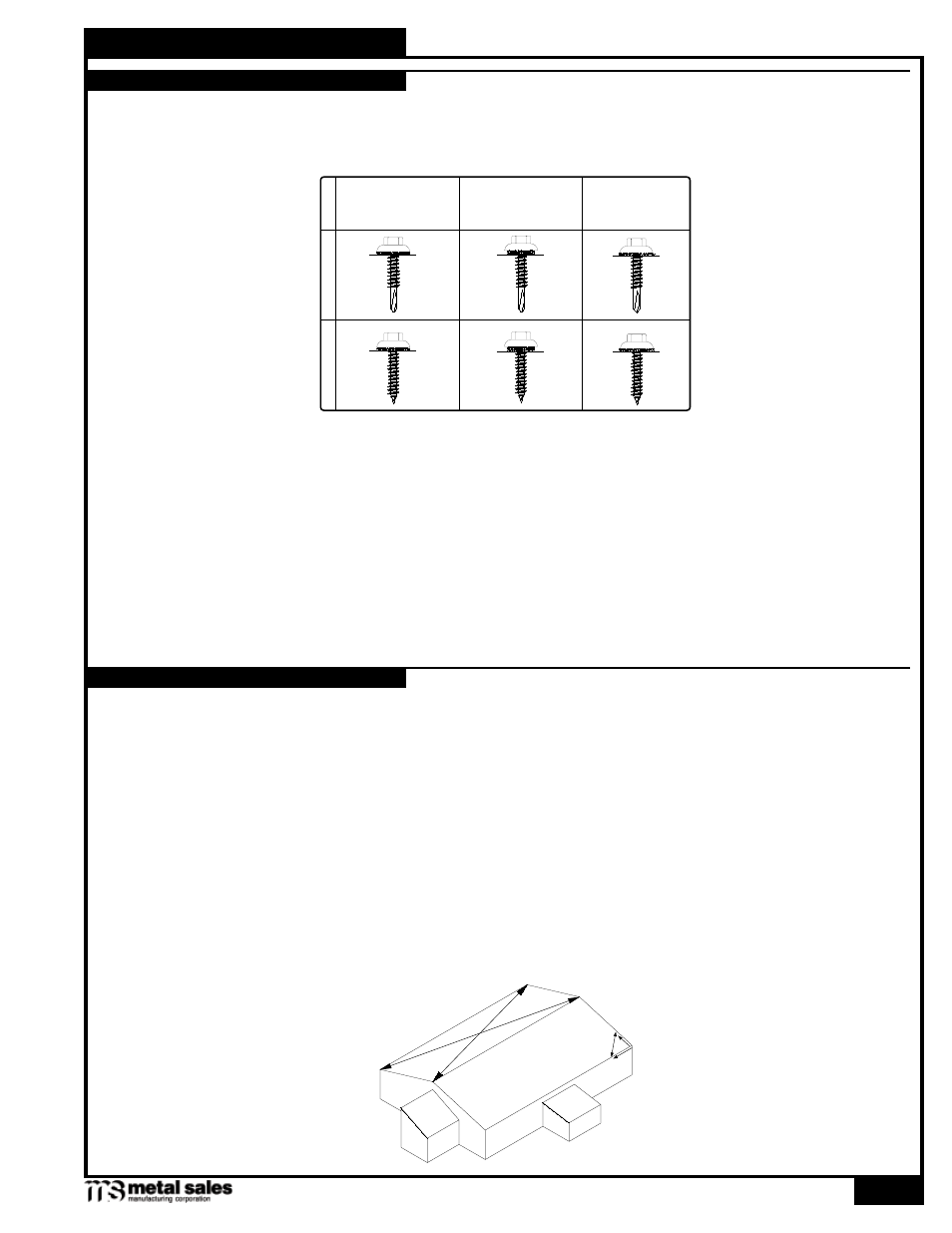

To prevent wobbling - Make sure fastener head is completely engaged in the socket. If the head does not go all the way in

the socket - tap the magnet deeper into the socket to allow full head engagement. Metal chips will build up from drilling and

should be removed from time to time.

Protect drill point - Push only hard enough on the screw gun to engage clutch. This prevents excess friction and burn out of the

drill point. Correct pressure will allow screw to drill and tap without binding.

Drilling through sheet and insulation - Ease up on pressure when drilling through insulation to avoid striking the purlin or girt

with the point - apply more pressure after drill point contacts purlin or girt.

Drilling through purlin overlaps - Drilling through lapped purlins requires extra care. Excessive voids between purlins

sometimes damages drill points and two self-drillers might be necessary to complete the operation. It is sometimes advantageous

to predrill.

Recommended Tool Type - Use depth locating nose or adjustable clutch on screw gun to prevent overdrilling and strip out.

Do not use impact tools or runners.

Seating the washer - Apply sufficient torque to seat the washer - do not overdrive the fastener.

TOO LOOSE

Sealing material is not visible;

not enough compression to

seal properly.

CORRECT

Sealing material slightly vis-

ible at edge of metal washer.

Assembly is watertight.

TOO TIGHT

Metal washer deformed;

sealing material pressed

beyond washer edge.

WOODSCREW

SELF DRILLER

FASTENER INSTALLATION TECHNIQUE

Whether over solid substrate or open structural framing, panel distortion may occur if not applied over properly aligned and

uniform substructure.

The installer should check the roof deck for squareness before installing Exposed Fastened panels. Several methods can be used to

verify squareness of the structure for proper installation of the panels.

METHOD "A" - One method for checking the roof for squareness is to measure diagonally across one slope of the roof from

similar points at the ridge and eave and obtain the same dimension.

METHOD "B" - The 3-4-5 triangle system may also be used. To use this system measure a point from the corner along the edge

of the roof at a module of three (3). Measure a point from the same corner along another edge at a module of four (4). Then by

measuring diagonally between the two points established, the dimension should be exactly a module of five (5) to have a square

corner. Multiple uses of this system may be required to determine building squareness. If the endwall cannot be made square, the

roof system cannot be installed as shown in these instructions.

CONDITION OF SUBSTRUCTURE

METHOD A

METHOD B

4

30

30

3

5