Discharging the mixer, Lubrication – Marshalltown 1220MP Mortar/Plaster Mixer User Manual

Page 12

12 of 44

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.MARSHALLTOWN.com

WS1169

6-2014/Rev.A

DISCHARGING THE MIXER

Keep hands and all foreign objects clear of the moving paddles while discharging the mixer.

DANGER!

MANUAL DUMP

1. Allow the entire mixture to mix for one (1) full minute.

2. DO NOT STOP MIXER FROM ROTATING.

3. Hold the tilt handle and disengage the drum lock.

4. Dump motor to the side by pulling the tilt lever downward.

5. After the mixture is dumped, return the drum to the operating position and engage drum lock.

RAM DUMP

1. Slowly push forward on the left-hand control lever on the control valve. The farther the valve is pushed, the faster the drum

will tilt.

2. With the drum in the discharge position, use the right-hand control lever to engage the paddles and discharge the mix.

3. Pull the left-hand control lever toward you to return the drum to the load/mix position.

LUBRICATION

To avoid personal injury, always turn off engine/motor and wait for all motion to stop before making

adjustments or repairs.

DRUM SEAL PLATE ASSEMBLIES

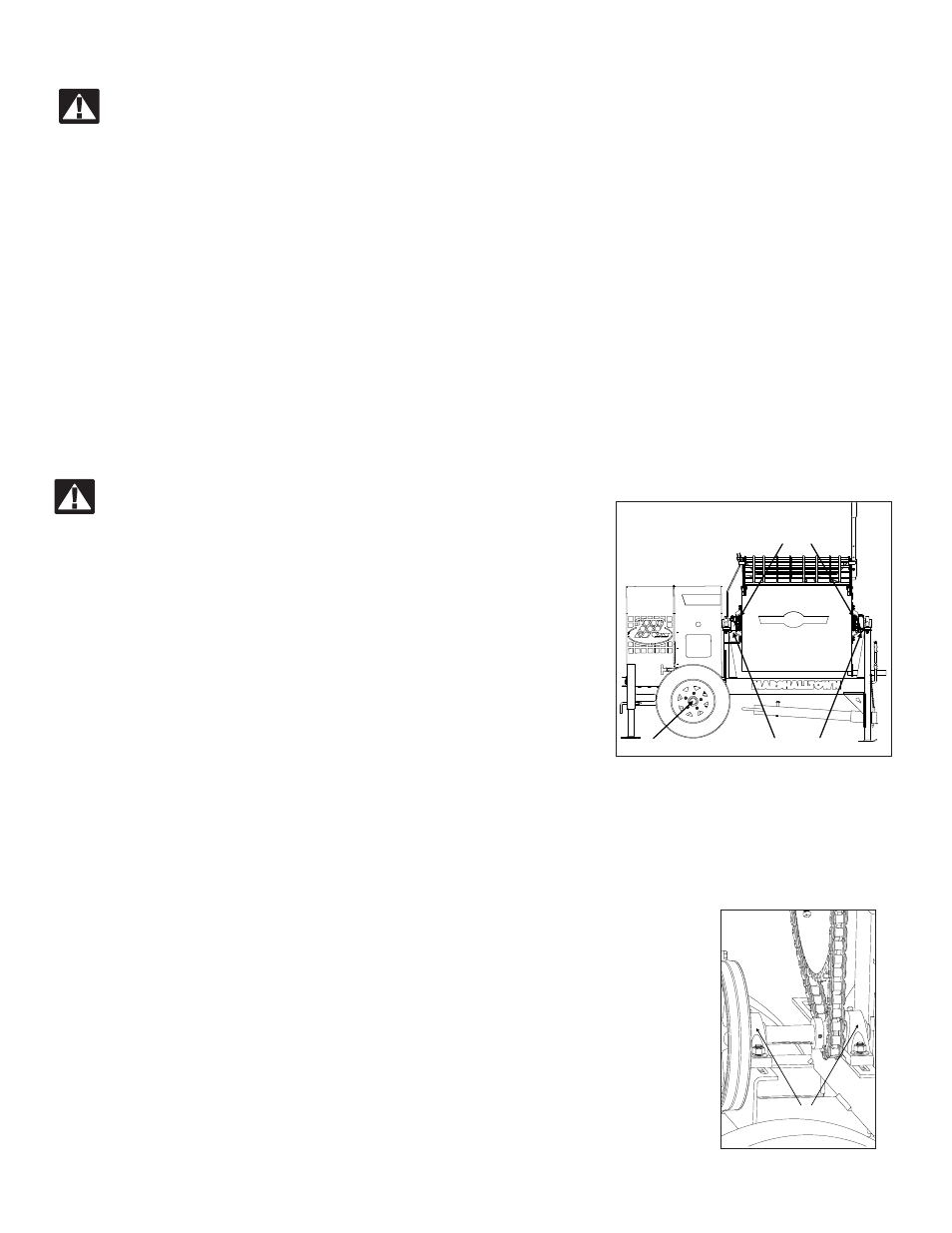

Drum seals are provided on each end of the drum where the mixing shaft passes

through to the bearings. It is important to pump grease into the assemblies to

retain seal efficiency. Use enough grease to flush out old grease and carry away

any grit. Use lithium based grade 2 multi-purpose grease. See Figure 3.1

MIXING SHAFT BEARINGS

The mixing shaft bearings are permanently factory sealed and lubricated, and

should not require further service.

WHEEL BEARINGS

Wheel bearings should be packed once a year. Thoroughly clean old lubricant from the bearings, hub and spindles before

repacking. Pack bearings only one-half to two-thirds full with grease to prevent overheating. Use no. 2 wheel bearing grease.

DRUM SHAFT BEARING HANGERS

Drum yoke bearing hangers are located on each side of the drum, and are equipped with grease fittings. These bearings

should be lubricated once each week with lithium based grade 2 multi-purpose grease.

See Figure 3.1

ENGINE/MOTOR

Refer to the engine/motor operating instructions for all maintenance and lubrication instructions

and requirements.

DRIVE SHAFT BEARINGS

Pillow block style bearing are used on the drive shaft. See Drum Seal Plate Assemblies,

Lubrication Guidelines for more information.

See Figure 3.2

WARNING!

Drum Seal Plate Assemblies

Drum Shaft Bearing Hangers

Wheel Bearings

Figure 3.1

Drive Shaft Bearings

Figure 3.2