5 assembly / installation, 1 preparations, 3 installation – Lenze MGXQK DC motors User Manual

Page 9: 4 electrical connection, Assembly / installation

9

5. Assembly / Installation

5.1 Preparations

¯

Unpack motors and check for transport

damages.

¯

If necessary, remove fastening device of

the key and residuals of the corrosion

protection.

¯

The motors were checked at the factory

and are ready for use.

5.2 Site of installation, nominal conditions,

and influencing factors

n

Do not operate in hazardous areas !

The motors are designed for the following

nominal conditions:

¯

Supply with half-- or fully controlled bridge

rectifier

¯

Rated power is based on a current form

factor of

F

F

= I

eff

/ I

arithm.

= 1.05

(see chapter 4.2.1)

¯

Ambient or cooling air temperature up to

+40 5C (see chapter 4.2.1)

¯

Installation height up to 1000 m above sea

level (see chapter 4.2.1)

¯

Operation within the permissible control

range or self--ventilated motors

¯

Ensure unimpeded flow of incoming and

outgoing air

¯

Avoid re--circulating of warm outlet air by

the motor

5.3 Installation

n

Ensure that no foreign matter penetrates

into the motor during assembly and

commissioning!

¯

Prepare fixing according to the design,

weight, and torque of the motor.

¯

Before fixing the motor, the foot and flange

faces must evenly rest on. Insufficient

alignment of the motors reduces the life of

the bearings and transmission elements!

n

Assembly of clutches and other

transmission elements according to the

instructions. To prevent damage of the

bearings, avoid under all circumstances

impacts on shafts and exceeding of the

permissible radial and axial forces!

¯

Ensure sufficient space for unimpeded

maintenance.

5.4 Electrical connection

n

Make electrical connections only when no

voltage is applied! Danger of unintended

startings or electrical shocks.

n

Electrical connections must only be made

by skilled personnel.

¯

Operate DC shunt motors only at DC

voltage. The supply is normally via DC

speed controllers. Make sure that the

supply voltage / controller output voltage is

identical with the nameplate data.

¯

A separate blower, which may be

connected, requires a single--phase or

three--phase AC voltage according to the

nameplate.

¯

A spring--loaded brake, which may be

attached, requires a suitable DC voltage or

an AC voltage which corresponds to the

connected rectifier.

¯

Dimension the connecting cables

sufficiently large to avoid a

non--permissible heating.

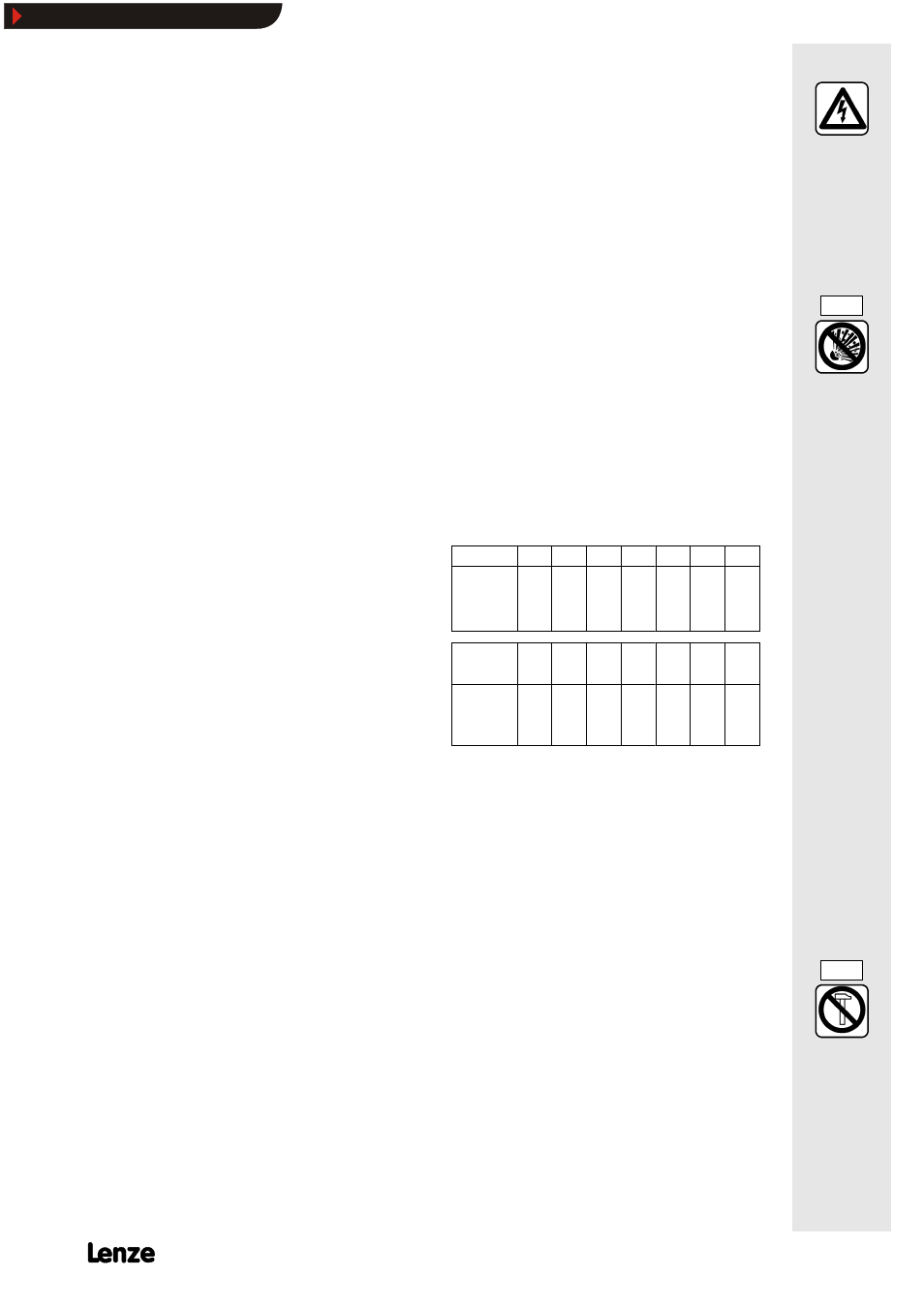

current [A] ≤6 ≤10 ≤16 ≤20 ≤25 ≤35 ≤50

Cable

cross-section

[mm

2

]

0.75

1

1.5

2.5

4

6

10

Rated

current in [A]

≤63 ≤80 ≤100 ≤125 ≤160 ≤200 ≤250

Cable

cross-section

in [mm

2

]

16

25

35

50

70

95

120

When the cables are very long, select a

cross--section one size larger to reduce

losses.

¯

The motor cable cannot be protected by

the thermal sensors of the motor winding.

Provide measures according to DIN 57100

/ VDE 0530.

¯

Make electrical connection according to

the connecting diagram which is attached

to every motor. The connecting diagrams

for the standard factory design are shown

in fig. 2 and fig. 3.

5.2

5.3

Show/Hide Bookmarks