Lenze MGXQK DC motors User Manual

Page 16

16

Checking and replacing carbon brushes

1. For MGXRK series:

Dismantle blower hood and tightening

strap.

For MGXQU series:

Dismantle cover sheets at the B--side

endshield.

2. Loosen carbon abrasion inside the motor

using a brush and suck off.

Do not blow out, because the dust may be

blown inside the motor and in the winding

heads.

3. Take off spring of the brush holder, take out

carbon brushes and measure the length of

the brushes:

-- The carbon brushes are marked with

letters. The lower edge of the letters is

the wear limit.

-- If this limit is almost reached, always

replace the carbon brushes in sets.

Only use genuine carbon brushes or

those approved by the manufacturer,

otherwise the commutation and brush

life are endangered (for orders see

chapter 8.2).

4. Insert carbon brushes such that they easily

slide in the brush holders.

Place the wires such that the carbons can

slide without being obstructed, when they

are shortened due to wear.

5. To ensure a good electrial contact between

carbon brushes and collector, grind the

carbon brushes such that they are adapted

to the collector diameter before the motor

is commissioned:

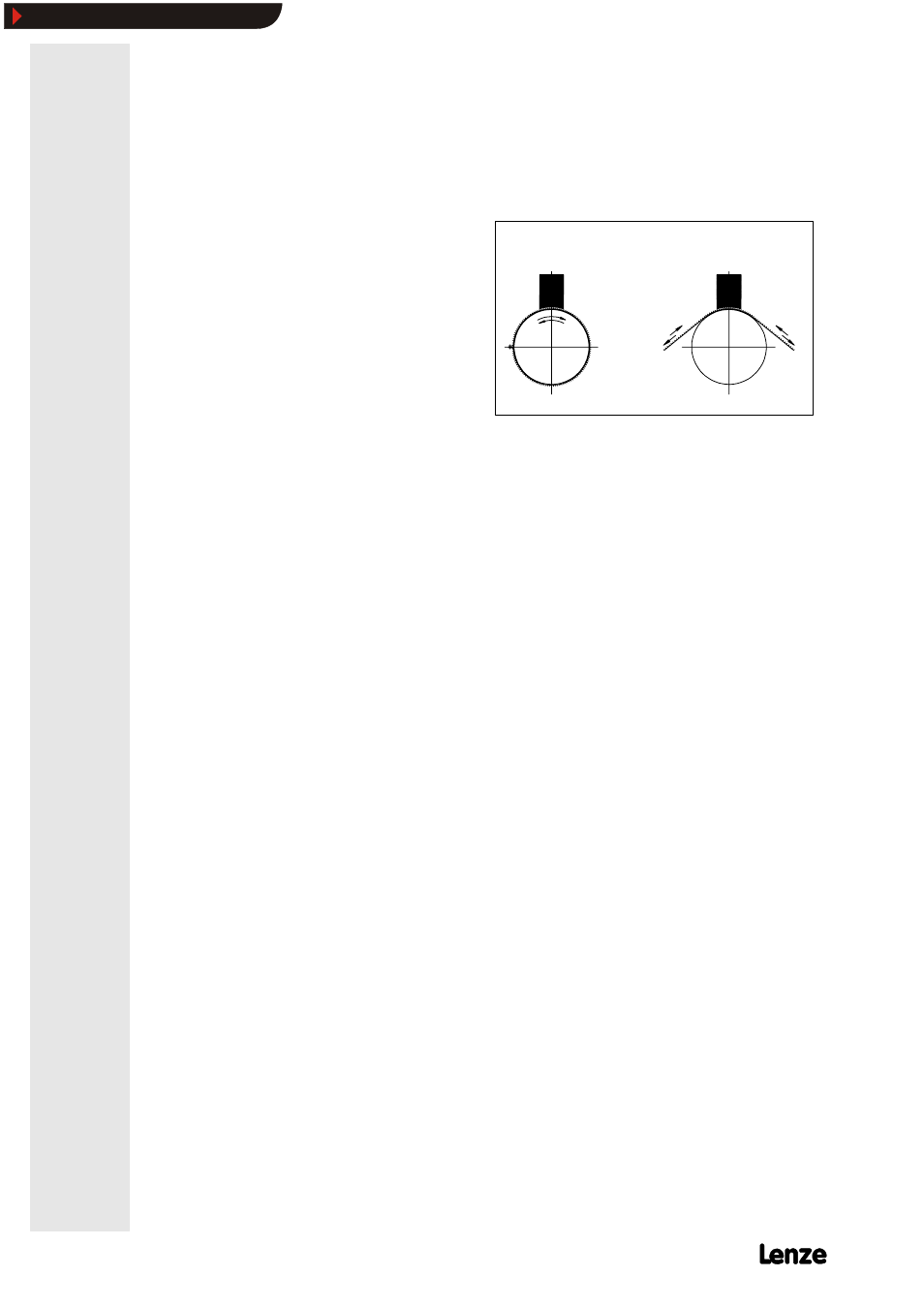

-- For motors which have free access to

the shaft ends and where the rotors can

easily be rotated by hand (fig. 4,

sketch 1):

Fix abrasive paper or abrasive cloth of

grain 180 or hold by hand.

Insert the new carbon brushes and

place spring of the brush holder on the

carbon brushes.

Then turn the rotor of the motor to both

sides until the contact surface of the

carbon brushes has completely adapted

to the running surface diameter of the

collector.

-- For heavy motors which are difficult to

move and those motors the shafts ends

of which are not accessible, the carbon

brushes of each pole must be ground

separately (fig. 4, sketch 2):

Lay a strip of abrasive paper or abrasive

cloth of grind 180, the length of which

corresponds to the length of the

collector running surface, between the

running surface and the brush holders of

a pole.

Insert the new carbon brushes and

place the spring on the carbon brushes.

By moving the abrasive paper under the

carbon brushes to both sides along the

collector shape, grind all carbon

brushes of a pole at the same time.

sketch 1

sketch 2

K33.0005

Fig. 4: Grinding of carbon brushes

6. Take carbon brushes out of the brush

holders. Carefully remove grinding and

carbon dust.

7. Insert carbon brushes again.

8. After disconnecting and turning the brush

yoke:

-- Set ”neutral zone” again. For this, the

mark at the brush yoke and the

endshield must exactly coincide.

Reconnect brush yoke.

9. For MGXRK series:

Reassemble tightening strap and blower

hood.

For MGXQU series:

Reassemble cover sheets.

The motor is now ready to operate again.

Show/Hide Bookmarks