4 recognition of incorrect operating conditions – Lenze MGXQK DC motors User Manual

Page 18

18

7.4 Recognition of incorrect operating

conditions

The function of the collector and the carbon

brushes is influenced by many factors. For

example humidity, pollutants in the air in the

form of gases, oil or solvent spray etc. as well

as a very low temperature of the cooling air,

low loads over a long time or vibrations acting

on the motor are decisive factors for the

commutation and wear of collector and

carbon brushes.

A prerequisite for a good function of the

carbon brushes is the right choice of the

brush material and the correct total

cross--section of the carbon brushes of each

pole, which must be perfectly adapted to the

motor and the operating conditions of the

motor.

Lenze have a long experience in

manufacturing motors and selecting optimum

carbon brushes. For special operating /

ambient conditions the brush material and the

number of carbon brushes can be adapted

for an optimum wear.

Before selecting another type of carbon

brushes, always contact the Lenze Service.

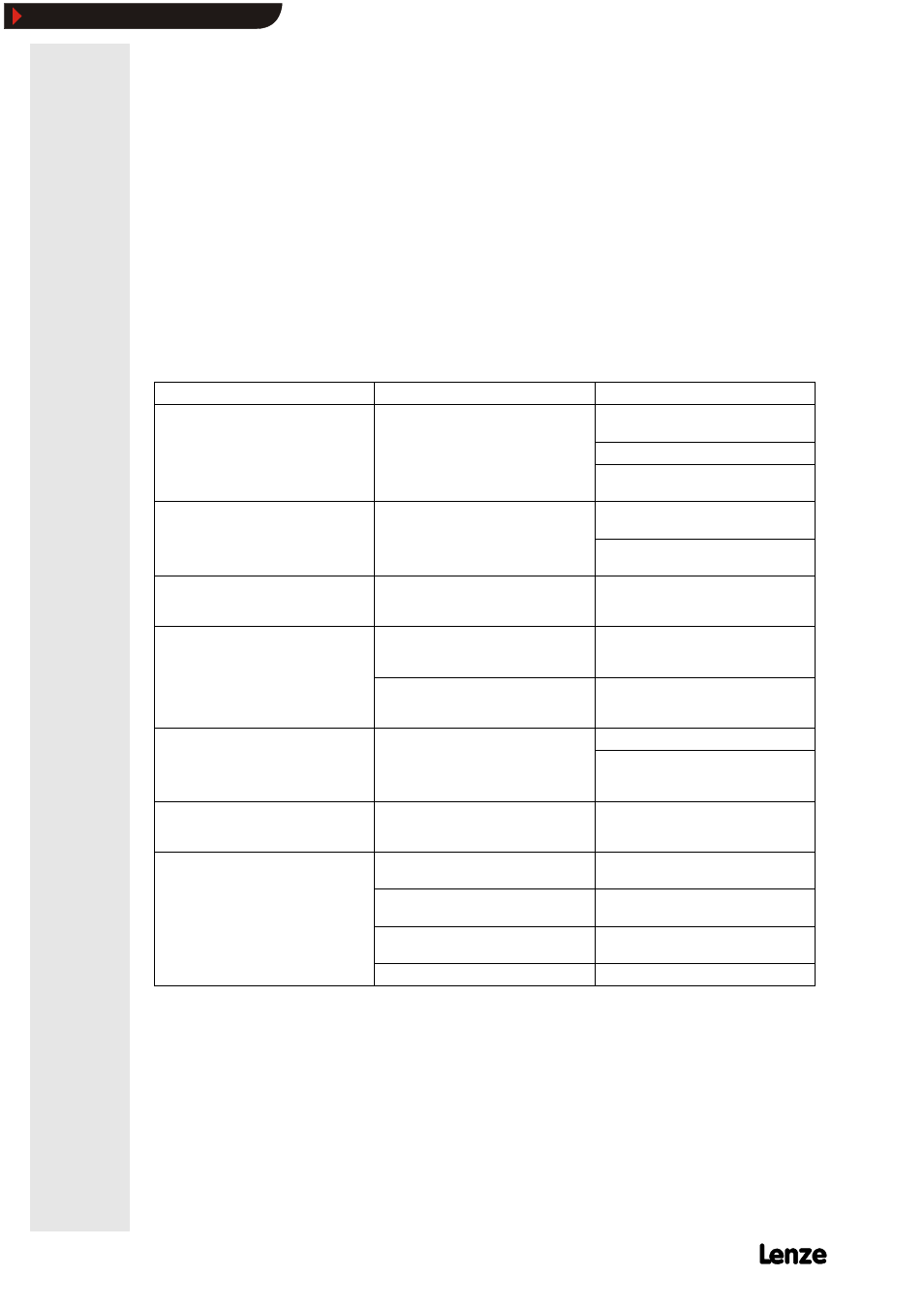

In the following, some troubles, possible

causes and measures to improve the

commutation and the wear are listed:

Fault

Cause

Remedy

Sparking,

increased brush wear,

black coarse spots on the collector s rface

Penetration of oil or oil spray

Avoid penetration of oil into the collector area

by sealing

black, coarse spots on the collector surface

Remove pollutions

Slightly grind the collector and thoroughly

clean carbon brushes

Sparking,

chatter marks on collector and carbon brush

r nning s faces

Solid dust particles under the carbon brushes

cause chatter marks

Where necessary, ensure efficient protection

against dust using filter elements

running sufaces

Supply motor with clean cooling air via a tube

system

Sparking,

collector surface has the colour of copper,

increased wear

Formation of patina impossible because of

very dry air

Increase humidity by air-conditioning of the

operating rooms or by other measures

Insufficient or missing patina,

run-in marks at the collector

Temperature of the collector surface and the

carbon brushes too low for the formation of

patina

Increase ambient temperature and thus the

cooling air temperature

Very low cooling air temperature or motor

operation with a considerably lower load

current than the rated current over a long time

Reduce carbon brushes according to the load

Contact the Lenze Service

Strong sparking,

bl e or green lights

High motor overload

Reduce motor load

blue or green lights,

burns at the bar edges and chipping at the

edges of the carbon brushes

Check field supply,

measure armature current and adapt to the

rated current

Sparking,

excessive wear of carbon brushes,

collector with clear chatter marks

Operation in rooms with chemically polluted

atmosphere

Supply motor with clean cooling air using

suitable filter elements or supply of external

fresh air

Sparking,

burnings at the collector,

increased wear

Insufficient contact between carbon brushes

and collector

Clean collector in regular intervals

increased wear

Acumulation of carbon dust and other

pollutants

Check if carbon brushes can easily slide in the

brush holders

Missing pressure

Ensure easy sliding of the carbon brushes with

continuing wear

Reduction of the pressure by high accelerations

Fit stronger springs in the motor

Show/Hide Bookmarks