4 fault - cause - remedy – Lenze MGXQK DC motors User Manual

Page 14

14

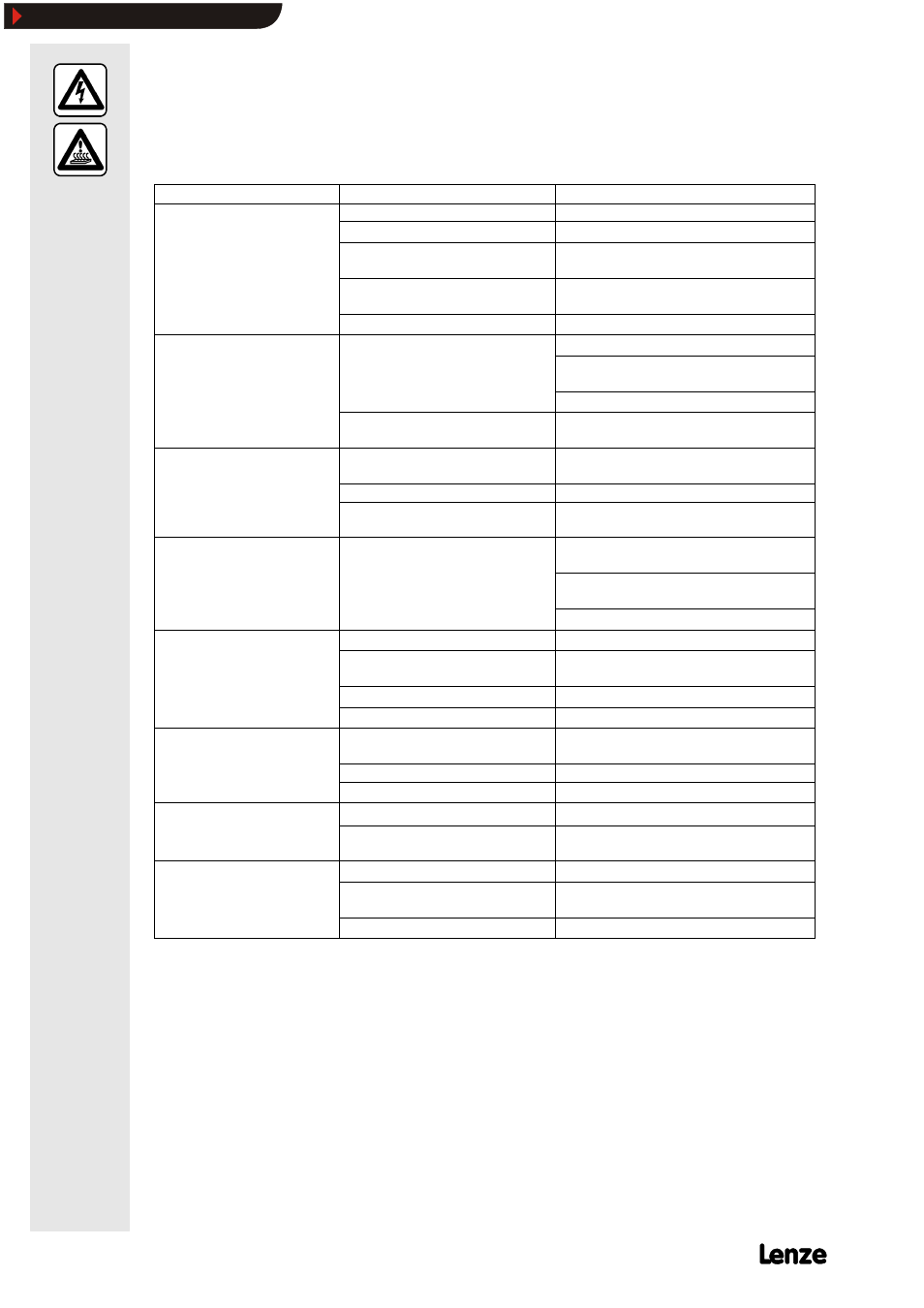

6.4 Fault -- Cause -- Remedy

n

Maintain and repair the drive only when no

voltage is applied!

n

High temperatures of the motor surfaces.

Keep cooling times!

n

Remove loads from the motor or secure

loads acting on the drive!

Interferences

Fault

Cause

Remedy

M t d

t t t

P

l i t

t d

Ch k l t i l

ti

( h t 5 4)

Motor does not start

Power s pply interr pted

Check electrical connection (chapter 5 4)

Motor does not start

Power supply interrupted

Check electrical connection (chapter 5.4)

Motor does not start

Controller inhibited

Check controller display check controller enable

Controller inhibited

Check controller display, check controller enable

No carbon br shes or not correctly installed

Check if br sh set complete and placed correctly

No carbon brushes or not correctly installed

Check if brush set complete and placed correctly

No carbon brushes or not correctly installed

Check if brush set complete and placed correctly

(chapter 7.1)

(chapter 7.1)

Armat re coils defective or short-circ ited

Remove short circ it (often only possible is a special

Armature coils defective or short-circuited

Remove short circuit (often only possible is a special

workshop or by the man fact rer)

workshop or by the manufacturer)

Excitation winding interr pted

Remove interr ption

Excitation winding interrupted

Remove interruption

Motor does not start

Brake does not release

Check electrical connection

Motor does not start

(high c rrent cons mption)

Brake does not release

Check electrical connection

(high current consumption)

Check air gap ’s

L

’ (see operating instr ctions of the

(high current consumption)

Check air gap ’s

Lü

’ (see operating instructions of the

brake)

brake)

Magnetsp le berpr fen

Magnetspule überprüfen

Drive is blocking

Check for free r nning of components ( remove foreign

Drive is blocking

Check for free running of components ( remove foreign

matter if necessary)

matter, if necessary)

S rface temperat re > 90 5C

Overload of the drive

Check c rrent cons mption check load and red ce if

Surface temperature > 90 5C

Overload of the drive

Check current consumption, check load and reduce, if

necessary

necessary

H t di i ti

b t

t d b d

it

Cl

f

f th d i

Heat dissipation obstr cted by deposits

Clean s rface of the drive

Heat dissipation obstructed by deposits

Clean surface of the drive

Cooling d cts inside the motor are obstr cted

Remove deposits inside the motor

Cooling ducts inside the motor are obstructed

by deposits

Remove deposits inside the motor

by deposits

Motor s ddenly stops and does not

Thermal contact interr pts power s pply

Red ce load allow motor to cool (for cleaning see

Motor suddenly stops and does not

start again

Thermal contact interrupts power supply

Reduce load, allow motor to cool (for cleaning see

above)

start again

above)

Check cooling effect (direction of rotation) of the

Check cooling effect (direction of rotation) of the

separate blower

Clean or replace filter element of the separate blower

Clean or replace filter element of the separate blower

Uneven r nning motor stops for a

Carbon br shes are worn

Replace br sh set (chapter 7 1)

Uneven running, motor stops for a

short time

Carbon brushes are worn

Replace brush set (chapter 7.1)

g,

p

short time

Carbon br shes are jamming abrasive matter

Cleaning of the inner part (chapter 7 1)

short time

Carbon brushes are jamming, abrasive matter

in the g idance

Cleaning of the inner part (chapter 7.1)

in the guidance

Winding contact in the armat re windings

Repair in the workshop or by the man fact rer

Winding contact in the armature windings

Repair in the workshop or by the manufacturer

Bar contact at the collector

Check collector and remove contact between the bars

Bar contact at the collector

Check collector and remove contact between the bars

Uneven running (vibrations)

Insufficient balancing of coupling elements or

Rebalancing

Uneven running (vibrations)

Insufficient balancing of coupling elements or

working machine

Rebalancing

I

fi i t li

t f th d i

t i

R

li

hi

t h k b

if

Ins ficient alignment of the drive train

Re-align machine set check base if necessary

Insuficient alignment of the drive train

Re-align machine set, check base, if necessary

Fixing screws are not tightened

Check screw connections and sec re

Fixing screws are not tightened

Check screw connections and secure

Excessive speed motor oscillates n

Br sh yoke shifted from the ne tral zone

Coincide colo r label at the br sh yoke and endshield

Excessive speed, motor oscillates un-

Brush yoke shifted from the neutral zone

Coincide colour label at the brush yoke and endshield

Excessive speed, motor oscillates un-

der load

Brush yoke shifted from the neutral zone

Coincide colour label at the brush yoke and endshield

der load

Interference of excitation current circuit

Check excitation current and voltage, eliminate cause

Interference of excitation current circuit

Check excitation current and voltage, eliminate cause

of interference

Noise

Carbon br shes are not r n-in

S pport r n-in (chapter 7 1)

Noise

Carbon brushes are not run-in

Support run-in (chapter 7.1)

Foreign matter inside the motor

Cleaning of the inside area of the motor, repair by

Foreign matter inside the motor

Cleaning of the inside area of the motor, repair by

manufacturer, if necessary

Bearings damaged

Replace bearings repair by man fact rer if necessary

Bearings damaged

Replace bearings, repair by manufacturer, if necessary

Show/Hide Bookmarks