4 example 2:write parameter, 4 process data, Example 2: write parameter – Lenze 2131IB User Manual

Page 32: Process data, Parameter setting, 4 example 2: write parameter

Parameter setting

6-9

BA2131EN

6.3.4

Example 2: Write parameter

Task

The heatsink temperature (value = 43

C) C0061 is to be read by the controller.

Job (byte 1/ service)

Bit 0-2 = 2

Write job

(xxxx x001)

Bit 3 = 0

Reserved

(xxxx 0001)

Bit 4-5 = 3

Data length 4 byte

(xx11 0001)

Bit 6 = X

Handshake changes frequently

(xx11 0001)

Bit 7 = 0

Only relevant with response

(0x11 0001)

SUBINDEX (byte 2)

Subindex = 0, as there is not subindex under code C0061.

INDEX (byte 3 + 4)

Index calculation:

Index = 24575 - code number

Index = 24575 - 61 = 24514 = 5FC2

hex

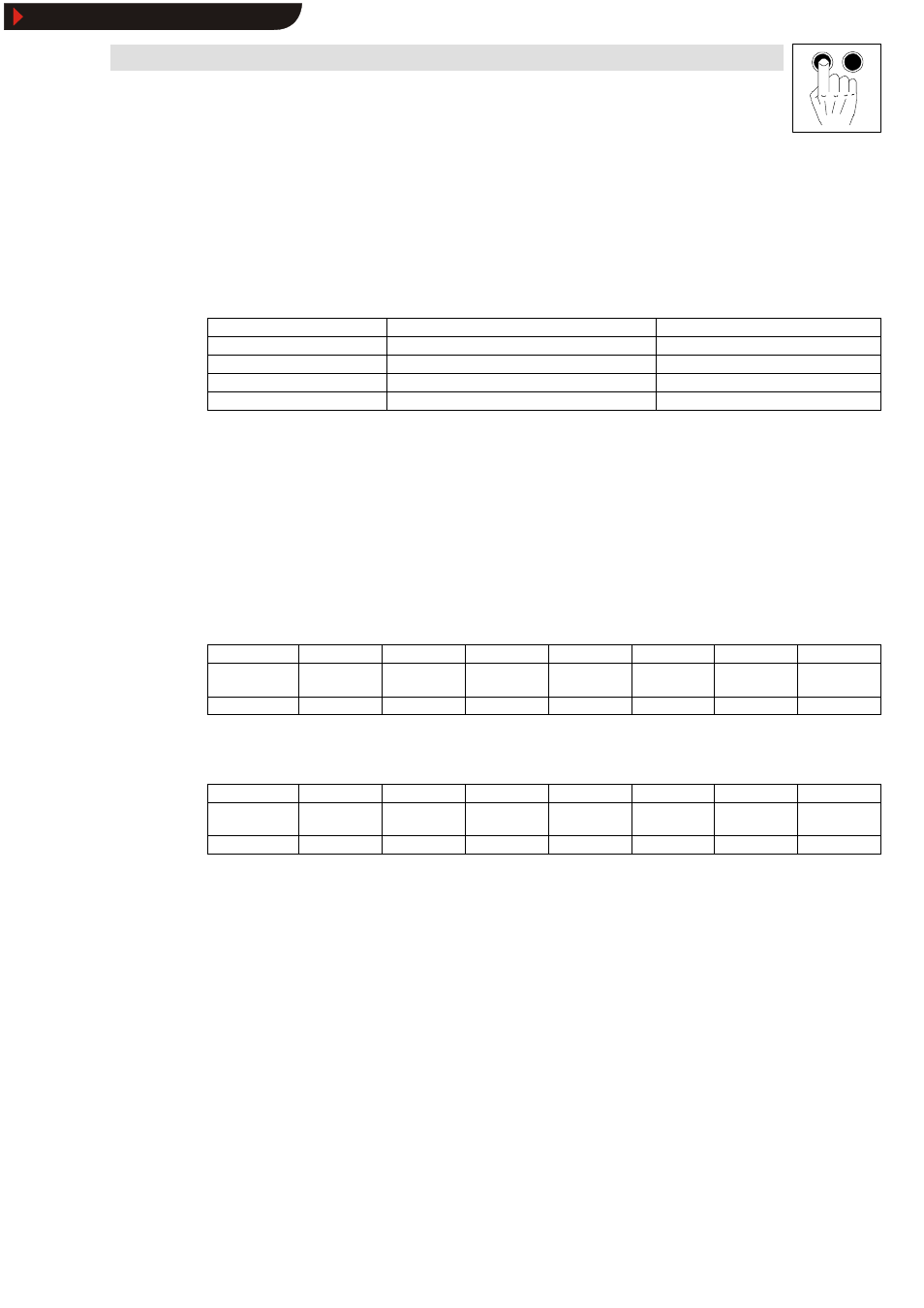

Response to drive

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8

Service

Subindex

Index

High byte

Index

Low byte

Data 4

Data 3

Data 2

Data 1

0x11 0001

0

5F

C2

00

00

00

00

Response of the controller when no fault occurs

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8

Service

Subindex

Index

High byte

Index

Low byte

Data 4

Data 3

Data 2

Data 1

0x11 0000

0

5F

C2

00

06

8F

B0

Index of the read request = 5FC2

hex

Data 1 to data 4 = 43

C x 10000 = 430000 = 00 06 8F B0

6.4

Process data

Process data are data memories in which several parameters for a new parameter - the process

data - are summarized for fast transmission. The host has direct access to the process data. In the

PLC, for instance, the data are directly assigned to the I/O area. These process data are cyclically

exchanged between the controller and the master. They are subdivided into

l

Process output data (PO data)

l

Process input data (PI data)

Here the data flow starts from the master, i.e. the PO data of the master are PI data for the controller.

The controller gets the control information from the master and returns status information.

Show/Hide Bookmarks