Start up & operation - engine drive – Kifco T40x1320 - Two Axle 380,601 - Present Operator Manual User Manual

Page 29

P/N 19302460

Copyright © April 2012 by Kifco

®

Inc.

Start Up & Operation - Engine Drive

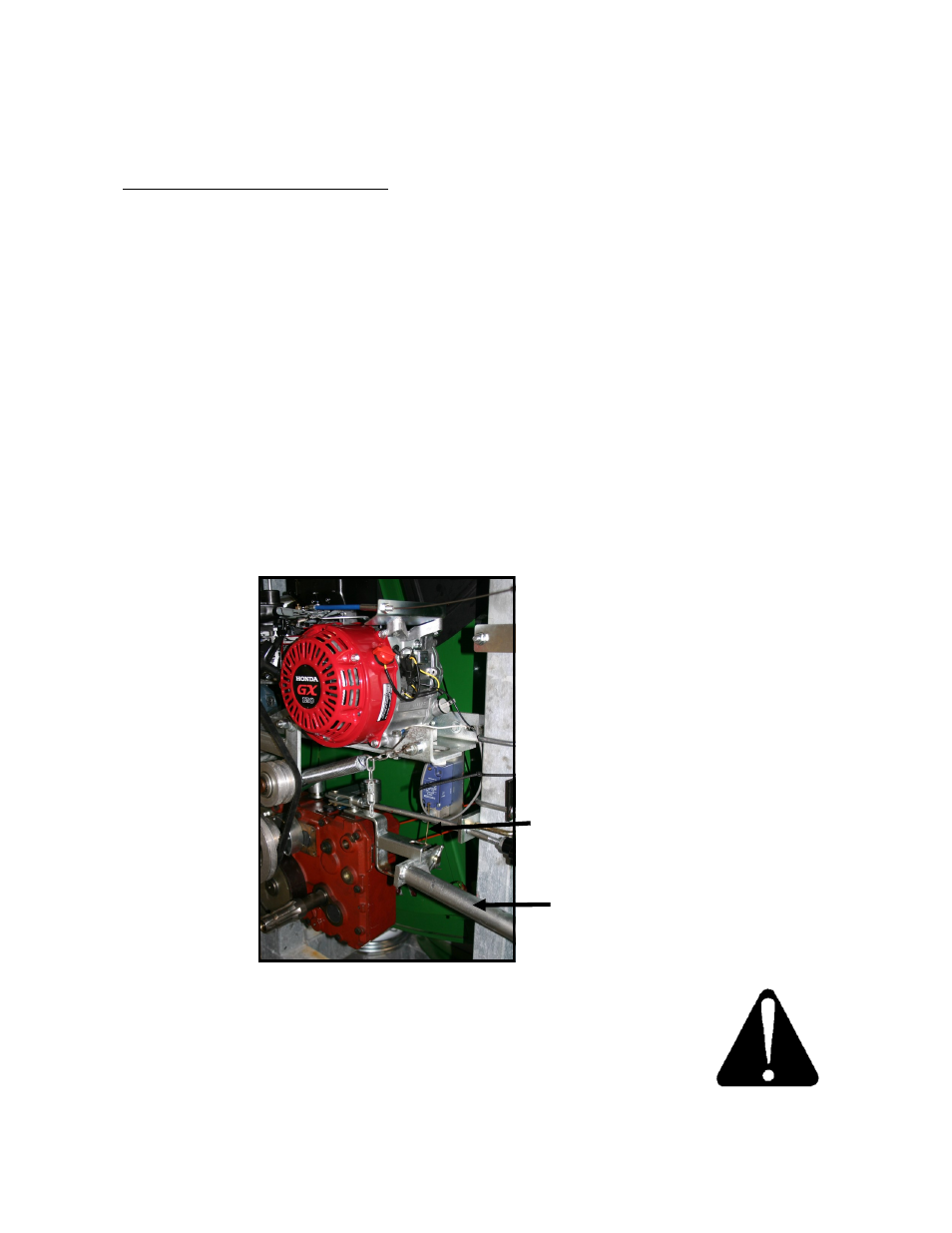

Engine Drive Shut-Off Switch Adjustment

There is seldom any adjustment required to the shutoff mechanism unless a part has been removed, replaced

or damaged.

When adjusting the engine shut-off switch, the tube should be on its last layer (Full Spool).

Position the bar as if it was on its last layer, the switch ramp should already be in contact with the wobble

switch. The wobble switch should just be on the verge of “clicking”. When the switch “clicks”, it grounds the

engine ignition & stops.

To ensure that the engine will not run after the irrigation cycle is complete, make sure the wobble switch

“clicks” before the gearbox is shifted into neutral. Once the gearbox is in neutral the sprinkler cart will not

advance the compensation/shut off bar and the engine grounding switch will be unable to ground the ignition

system. The engine will continue to run. As the sprinkler cart comes into the machine, the sequence of events

is as follows:

a. The sprinkler cart will contact the shut-off bar.

b. The shut-off rod and switch ramp will trip the wobble switch

c. The engine will shut-off automatically

Warning! Ensure that the gearbox shut off lever will trip the wobble switch be-

fore the shut-off bar has reached the level wind frame. If the shut-off bar is al-

lowed to reach the levelwind frame before engine shut down or before the

gearbox has been shifted to neutral, machine damage will occur.

Set switch rod to

point where switch is

nearly ready to click.

Gearbox Shutoff Lever

26

- E40x1250 380,601 - Present Operator Manual T40x1250 380,601 - Present Operator Manual E37x1220 380,601 - Present Operator Manual T37x1220 380,601 - Present Operator Manual E37x1080 380,601 - Present Operator Manual T37x1080 380,601 - Present Operator Manual E33x1120 380,601 - Present Operator Manual E30x1200 380,601 - Present Operator Manual T33x1120 380,601 - Present Operator Manual T30x1200 380,601 - Present Operator Manual E30x980 380,601 - Present Operator Manual T30x980 380,601 - Present Operator Manual