Start up & operation - engine drive, Setting the travel speed – Kifco T40x1320 - Two Axle 380,601 - Present Operator Manual User Manual

Page 28

P/N 19302460

Copyright © April 2012 by Kifco

®

Inc.

Start Up & Operation - Engine Drive

Engine Drive Water-Reels are powered by a 4 HP gasoline engine driving a set of two-step pulley reductions

and a two-speed gearbox that provides a wide speed range. Most engine powered Water-Reels have a travel

speed range from 60 ft/hr to 400 ft/hr. They are speed compensated by the engine throttle.

The engine used on these machines is the Honda GX-120 with a 6 Gallon fuel cell. Operating and service infor-

mation on the engine is provided by the engine manufacturer and is packed separately with the Water-Reel

engine drive machine.

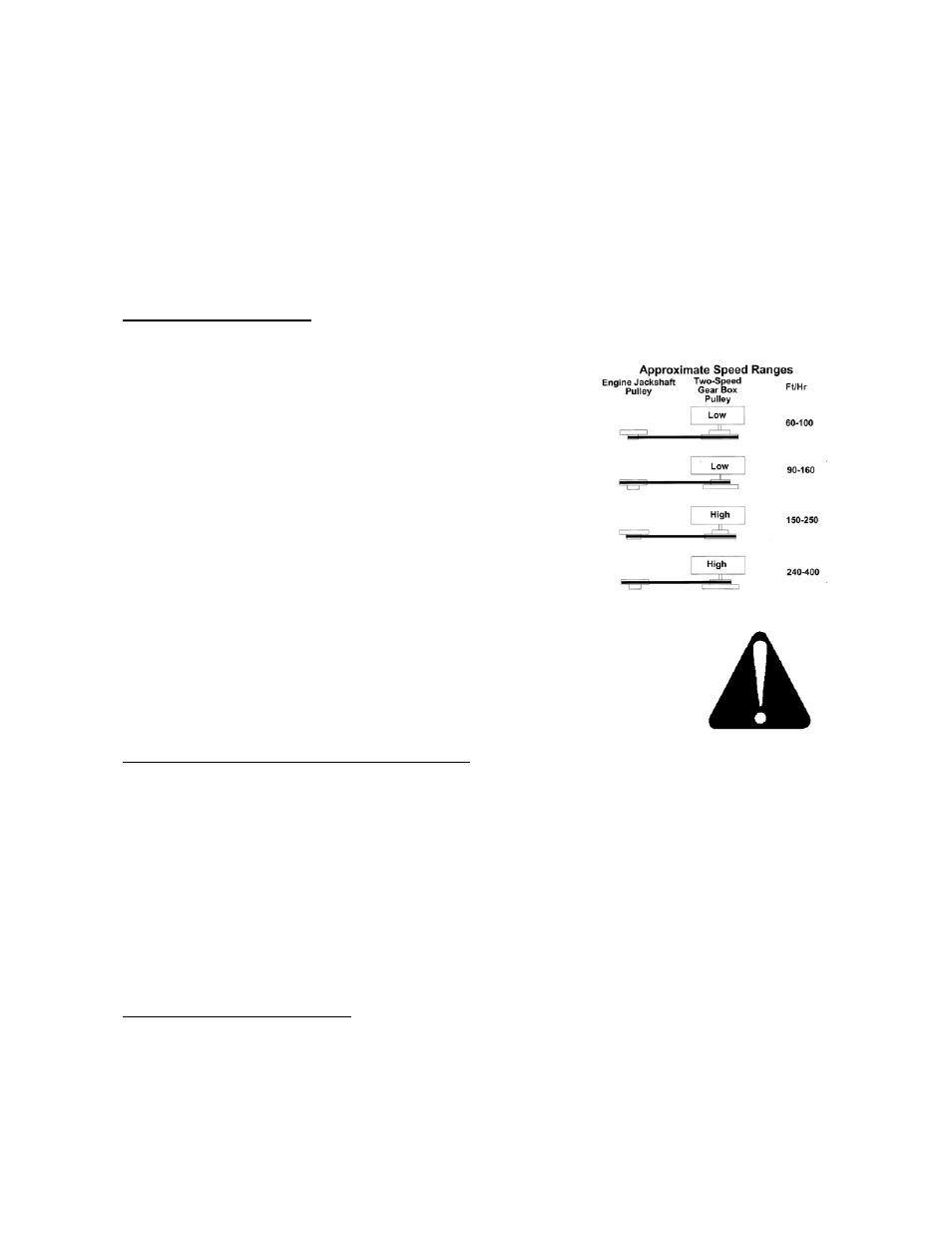

Setting the Travel Speed

1. Select the proper speed range from the following “Engine Drive

Speed Range” chart.

2. Select the desired Jackshaft Pulley setting based on desired speed

of retraction (Ft/Hr).

3. Select the desired gearbox setting with the right gearbox handle

(High or Low).

4. Loosen the speed control knob and slide the throttle link handle

until the desired speed is shown on the travel speed indicator. Re-

tighten the speed control knob. See the illustrations on page 22 for

the location of the controls.

5. As the machine progresses, the compensation/shut-off bar will

move the throttle linkage and maintain the travel speed as the irri-

gation tube accumulates on the spool.

Caution! Do not engage or disengage the gearbox under high loads. Engaging or disen-

gaging the gearbox under high loads may damage the gear train.

Caution! Never attempt to change gearbox from High to Low (Right Handle) when the

gearbox when the gearbox is under load. Serious damage could occur to the gearbox.

Steps for Removing Load for Gearbox Setting Changes

1. Stop machine (Turbine or Engine) and Pump

2. Confirm anti-reverse pawl is down (This pawl should be under load. If it is not, it is now safe to change

speed setting. If it is under load, continue to step 3.)

3. Use hand wheel to rotate gearbox PTO counter-clockwise, simultaneously lift the anti-reverse pawl and

allow the spool to slowly unwind (one gear tooth only).

4. Repeat step 3 until anti-reverse pawl is no longer under load.

5. It is now safe to change gears.

6. Before restarting your machine, confirm all remaining coils of tube are tight and neatly packed and that

the anti-reverse pawl is in the down position.

Engine Drive Speed Control Linkage

There is seldom any adjustment required to the speed control linkage unless a part has been removed, re-

placed or damaged. The engine should run at 3600 RPM with the control linkage at its maximum adjustment

and with no compensation (tube on first layer).

After starting engine loosen knob and adjust to required speed.

25

- E40x1250 380,601 - Present Operator Manual T40x1250 380,601 - Present Operator Manual E37x1220 380,601 - Present Operator Manual T37x1220 380,601 - Present Operator Manual E37x1080 380,601 - Present Operator Manual T37x1080 380,601 - Present Operator Manual E33x1120 380,601 - Present Operator Manual E30x1200 380,601 - Present Operator Manual T33x1120 380,601 - Present Operator Manual T30x1200 380,601 - Present Operator Manual E30x980 380,601 - Present Operator Manual T30x980 380,601 - Present Operator Manual