Bryant 355MAV User Manual

Page 16

A02350b

11

NO PREVIOUS CO

DE – Sta

tus

code

s

are

er

ased after

72 hours

or

can

be man

ua

lly

er

ased

b

y

putting setup s

w

itch

SW1-1

in

the

ON posi

tion

an

d jumper

ing

R,

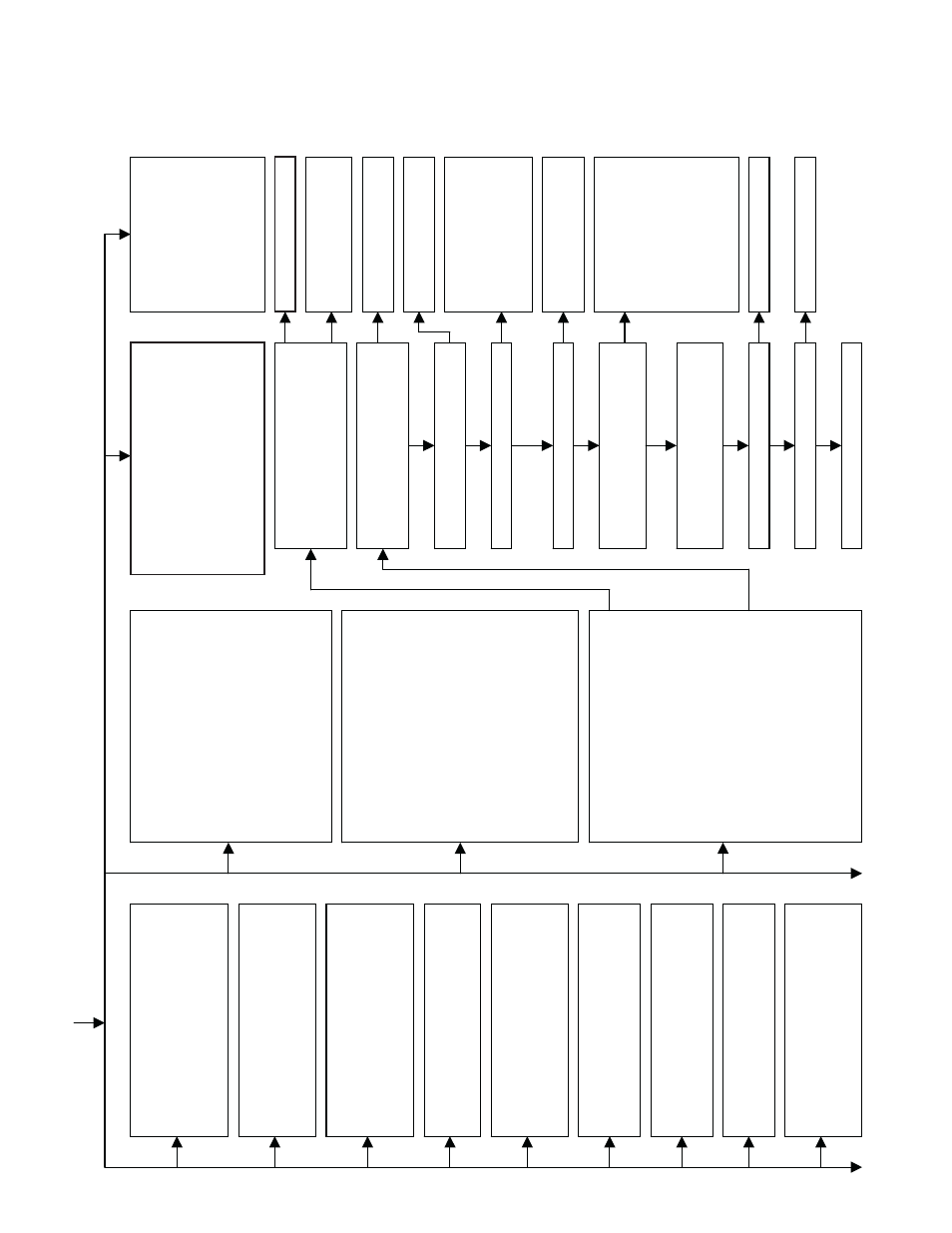

W/W1

,

and

Y

/Y

2

sim

ul

tane

ously

until statu

s

c

o

d

e

#11 is

fla

shed

.

Run sy

stem

through a lo

w

-

heat, high-hea

t, or

cooling

cy

cle to

che

ck

sy

stem

.

12

BLO

WER ON

AFTER PO

WER UP

–

(115V

OR 24V)

– Nor

mal oper

a

tion

.

Blo

wer r

uns f

o

r 90

seconds

, if uni

t is

po

wered up dur

in

g

a

call

fo

r heat (R-

W/W1

clo

sed)

or w

hen (R-

W/W1

ope

n

s

)

dur

ing

the

b

lo

w

er on-dela

y

period.

13

LIMIT C

IRCUIT LOCK

OUT – Loc

k

out

occurs if

the

limit or

flame

rollout s

w

itch is

open longer

than

3

min

utes or 10

succe

ssiv

e limit

tr

ip

s occurred

dur

ing high-

heat.

Control w

ill auto-re

se

t after 3 hours

.

See code

33.

14

IGNIT

ION LOCK

O

U

T – Sy

stem

faile

d

to

ignite

gas and pro

v

e flame

in 4 attempts

.

Control

w

ill auto-reset afte

r 3 hours

.

See

sta

tu

s code

34

.

21

GAS HEA

T

ING L

O

CK

OUT –

T

u

rn

off

po

wer and wait 5 min

ute

s

to

retr

y.

Check

fo

r:

-

Stu

ck close

d ga

s v

alv

e rela

y

on contro

l.

-

Mis

w

ire

or shor

t to

gas valv

e

w

ire

.

22

ABNORMAL FLAM

E-PR

O

VING

SIGN

AL

Flame is pro

v

ed w

h

ile gas v

a

lv

e is de-

energiz

e

d

.

Indu

cer

w

ill r

un un

til

f

a

ult is

cleared

. Che

ck

fo

r:

-

Stu

ck

open

or leaky

gas v

a

lv

e

.

23

PRESSURE SW

IT

CH DID NO

T OPEN –

Check f

o

r:

-

Obstr

u

cted

pressur

e tube

.

-

Pressure

s

w

itch stu

c

k closed.

24

SECOND

AR

Y

V

O

LT

A

GE FUSE

IS

OP

EN

Check f

o

r:

-

Shor

t ci

rcu

it in

se

co

ndar

y

v

oltage (24V)

w

ir

ing including

the

rmosta

t leads

.

Disconnect ther

mo

sta

t

lead

s to

isolate

short cir

cui

t.

32

LO

W

-HEA

T PRESSURE SW

ITCH DID

NO

T CLOSE

OR R

E

OPENED –

If ope

ns

dur

ing b

lo

w

er on-d

ela

y

per

iod,

b

lo

w

er w

ill

come on

fo

r the

sel

ecte

d b

lo

w

er off-dela

y

.

If opens w

ithin

5 min

ute

s after igniti

on

the

ne

x

t heating

cy

cle

w

ill be restr

icted

to

high-hea

t.

Che

ck

fo

r:

-

Proper v

ent sizing

.

-

L

o

w

inlet gas pressure (if LGPS

used).

-

Restr

icted comb

ustion

air

supply

.

-

Disconnected or obstr

ucted

pressu

re

tubing.

-

Def

ectiv

e or mis

w

ired pressure

s

w

itch

es

- Ex

cessiv

e

w

ind.

- Plugged

cond

ensa

te

dr

ain

.

-

W

a

ter

in v

ent pipin

g, possib

le

sagging

pipe

.

33

LIMIT C

IRCUI

T F

A

UL

T – Indicat

e

s

t

h

e

limit

o

r flame rollou

t

s

w

itch

is

open or the

fur

na

ce

is oper

atin

g in

high-hea

t only

mode due to 2 successiv

e lo

w

-heat limit

tr

ip

s

.

Blo

wer w

ill r

un f

o

r 4 min.

or

until

open

s

w

itch

remak

es w

h

iche

v

er is longer

.

If

open

longe

r than

3

min., cod

e chang

es

to loc

k

o

u

t #13.

If open less

than

3 min.

sta

tu

s code

#33

co

ntin

ue

s to

fla

sh

un

ti

l

b

lo

w

er shuts off

.

Flame rollou

t

s

w

itch

require

s man

ual reset.

Che

ck

fo

r:

-

Proper rear

air baffl

e

.

-

Loose

b

lo

w

er w

heel.

-

Def

ectiv

e s

w

itch

or

conne

cti

ons

.

-

Improper

lo

w-heat gas inpu

t

adj

ustme

nt.

-

Improper

or misalig

ned limit and/or

limit

shield.

-

Stu

ck high-heat

sol

enoid in gas v

a

lv

e

.

34

IGNIT

ION PRO

V

IN

G FAILURE

–

If

fla

me is

not sen

sed

dur

in

g the

tr

ial f

o

r

igni

tion

per

iod,

the con

trol

w

ill

repeat the

igni

ti

on

sequen

ce

3 more

ti

mes bef

ore

loc

k

out

#14

occurs

.

If

flame

sig

nal is lost dur

ing

the

b

lo

w

er on-dela

y

per

iod, b

lo

w

er w

ill come on

for the

sele

cted

b

lo

w

er

off-dela

y

.

Che

ck

the f

ollo

w

ing

it

ems first

bef

ore pro

ceed

ing

to

the

ne

x

t step

.

-

Gas v

a

lv

e tur

ned

off

.

- Man

ual

shut-off

v

a

lv

e

.

-

Green/Y

ello

w w

ire MUST be

conne

cte

d

to

fur

na

ce

sheet metal.

-

Flame sen

sor

m

ust not be

g

rounded.

T

o

dete

rmine w

hether

the

prob

lem

is in th

e

gas v

a

lv

e

, ignite

r,

o

r flame

sen

sor

the

sy

stem can

be oper

ated

in compone

nt test

mode

.

T

o

che

ck

th

e igniter

remo

v

e

the R

ther

mo

sta

t conn

ecti

on

from the con

trol

,

reset po

w

e

r,

and

put

s

e

tup

s

w

itch SW1-6 in

the ON

po

si

tion to

sta

rt

th

e component te

st.

Does

the

igniter

glo

w

or

ange/white b

y

the

end of

the

15

se

co

nd w

a

rm-up per

iod

?

Unplug igni

ter

har

n

e

ss

from

con

trol

an

d

repeat component

test b

y

tur

ni

ng

se

tup

s

w

itch S

W

1-6

OFF and then bac

k

ON.

Chec

k f

or 1

15V

betw

een pin 3 and

NEUTRAL-L2 on

th

e co

ntro

l.

Wa

s 115

V

presen

t

for

the 15

second

per

iod

?

Chec

k conne

cti

ons and

re

tr

y.

If current is near ty

pical

v

a

lue

(4.0-6

.0

nominal) and b

u

rn

e

rs

w

ill not

sta

y

on, repeat

che

ck

in high-h

eat.

If b

u

rners w

ill

stil

l not

sta

y

on replace

control.

If bur

ner

s

oper

ate in

high-heat then

s

w

itch to

lo

w-

heat, che

ck

mani

fo

ld

pressure

.

If OK,

c

h

e

c

k

b

u

rner

carr

yo

ver and flame

sen

sor

loca

tion

.

Clean flame

sen

sor

w

ith fine

steel w

ool

and re

che

ck

curren

t.

Nominal

curren

t is

4.0

to

6.0 microam

ps

.

Is

curren

t near

ty

pical v

a

lue?

Replace

ele

ctro

de

.

Will

main

b

u

rner

s

ignite

and sta

y

on?

Replace furnace

co

ntrol.

NO

YE

S

YES

YES

NO

NO

15

BLO

WER MO

T

O

R

LOCK

OUT –

Indi

ca

tes

the

b

lo

w

er f

ailed

to

reach

250

RPM or the

b

lo

w

er f

ailed

to

co

mmunicate w

ithin 30

seconds afte

r being

turned

ON in tw

o

succe

ssiv

e heating

cy

cles

.

Control w

ill

auto-re

se

t after

3 hours

.

See code

41.

45 CONTR

OL

CIRCUI

TR

Y

LOCK

OUT A

u

to-re

set

afte

r 1 hour loc

k

out due

to:

-

Flame

cir

cui

t

failu

re

.

-

Gas v

a

lv

e rela

y

stu

ck

open.

- Softw

are

che

ck

err

or

.

Reset po

w

er to

cle

ar

loc

k

out.

Repla

ce

control

if code

repea

ts

.

Replace furnace

co

ntrol.

Chec

k f

o

r

con

tin

u

ity

in the

har

ness

and igniter

.

Repla

ce

defec

tiv

e

c

o

mpon

en

t.

Reconne

ct the R

th

er

mostat lead

and

set

ther

m

o

sta

t

to

call

fo

r heat. Con

nect

v

o

ltmeter acro

ss gas v

a

lv

e connections

.

Does ga

s v

a

lv

e receiv

e 24V?

Does ga

s v

a

lv

e open and allo

w gas

to

flo

w?

Do the main b

u

rner

s ignite?

Do the main b

u

rner

s

sta

y

on?

Allo

w

b

lo

w

er to

co

me on and

repeat test

to

chec

k f

o

r

inter

mi

tten

t oper

a

ti

on.

Chec

k that all

gas v

a

lv

es are

tur

ned

on.

Replace

v

a

lv

e

.

Chec

k connecti

ons

.

If

OK

,

replace

control.

Check f

o

r:

-

Inadequa

te

flame

carr

yo

v

e

r

or rough ignition

.

-

L

o

w

inlet gas pressure

.

-

Proper

fir

in

g

rate

.

-

Air leakage

around

igniter

br

ac

k

et.

Repeat

call

for h

eat and check

flame

sen

sor

cur

rent dur

ing tr

ial

fo

r ignition

per

iod.

Is

the

DC

microamp

s bel

o

w

0.5?

YES

NO

43

LO

W

-HE

A

T

PRES

SURE S

W

ITCH OP

EN

WHIL

E HIGH-HEA

T PRESSURE

S

W

ITCH IS CLOS

ED -

Che

c

k f

o

r:

-

L

o

w

-heat

pre

ssure s

w

itch stu

ck

open

.

-

Disconnected or obstr

ucted

pressu

re

tubing.

-

Improper pressure

s

w

itch w

ir

ing.

-

L

o

w

inlet gas pressure (if LGPS

used).

-

Plugged

cond

ensa

te

dr

ain.

-

W

a

ter

in v

ent pipin

g, possib

le

sagging

pipe

.

YES

YES

YES

YES

NO

NO

NO

NO

Fi

x

ed.

NO

—16—