Bryant 355MAV User Manual

Page 10

CAUTION:

UNIT DAMAGE HAZARD

Failure of plastic components may occur.

Do not use ethylene glycol (Prestone II antifreeze/coolant

or equivalent automotive type).

6. Replace drain connection cap and clamp to inducer housing.

7. Replace main furnace door.

8. Propylene glycol need not be removed before restarting

furnace.

WIRING DIAGRAM

See Fig. 12, 13, and 18 for Wiring Diagram

TROUBLESHOOTING

Use the troubleshooting guide, the status code LED on the furnace

control and the component test to isolate furnace operation

problems.

A more detailed troubleshooting guide is available from your

distributor.

For an explanation of status codes, refer to service label located on

back of main furnace door. (See Fig. 17.)

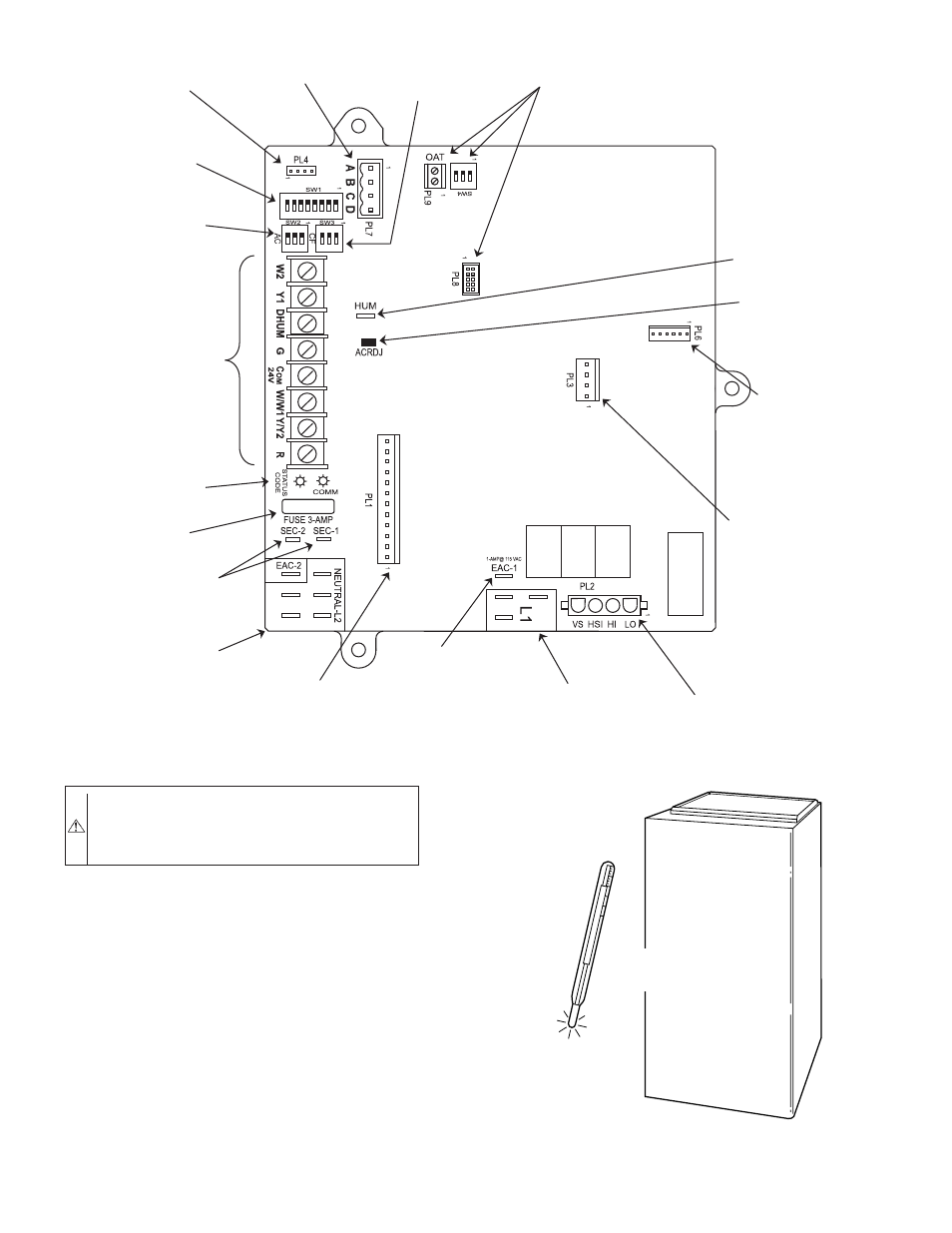

Fig. 13—Variable Capacity Furnace Control

A02278

FLASH

UPGRADE

CONNECTOR

(FACTORY

ONLY)

ACRDJ – AIR

CONDITIONING

RELAY DISABLE

JUMPER

HUMIDIFIER

TERMINAL (24-VAC

0.5 AMP MAX.

CONTINUOUS FAN

(CF) AIRFLOW

SETUP SWITCHES

COMMUNICATION

CONNECTOR

AIR CONDITIONING

(A/C) AIRFLOW

SETUP SWITCHES

MODEL PLUG

CONNECTOR

SW1 SETUP

SWITCHES AND

BLOWER OFF-

DELAY

STATUS AND COMM

LED LIGHTS

3-AMP FUSE

TRANSFORMER 24-VAC

CONNECTIONS

PL3 – ECM BLOWER

HARNESS

CONNECTOR

PL1 – LOW VOLTAGE MAIN

HARNESS CONNECTOR

EAC-1 TERMINAL

(115-VAC 1.0 AMP MAX.)

115-VAC (L1) LINE

VOLTAGE CONNECTIONS

115-VAC (L2) NEUTRAL

CONNECTIONS

PL2 – HOT SURFACE

IGNITER & INDUCER

MOTOR CONNECTOR

24-V THERMOSTAT

TERMINALS

FUTURE

APPLICATIONS

Fig. 14—Freeze Protection

A93058

32

°

F MINIMUM INSTALLED

AMBIENT OR FREEZE

PROTECTION REQUIRED

—10—