Automatic venting of a vacuum chamber, Max. turning the adjusting screw (6/2) clockwise – INFICON VSC150A absolute switch, passiv User Manual

Page 18

max. turning the adjusting screw (6/2) clockwise.

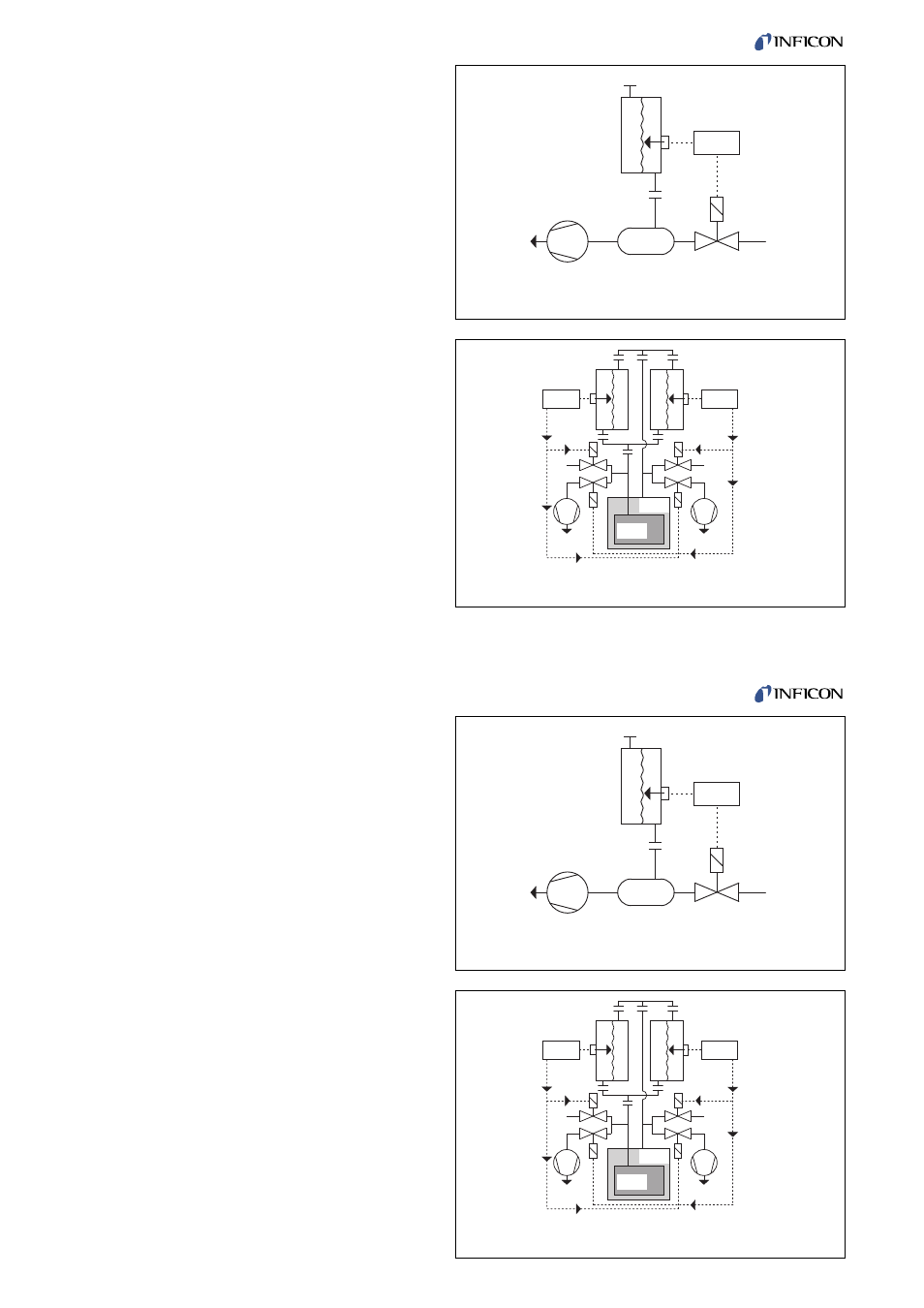

2.5.4 Automatic Venting of a Vacuum Chamber

to a Slight Overpressure

Assembly as in Fig. 9.

Loop the control circuit of the venting valve via the break

contact of the switching amplifier relay, terminals 12 and

13 (see Fig. 5). The switching pressure can be raised by

20 mbar max. above atmospheric pressure by turning

the adjusting screw (6/2) clockwise.

2.5.5 Differential Pressure Monitoring, Positive

and Negative Going

In an annealing plant with „holding vacuum“ pump down

and venting of the annealing pot and the vacuum fur-

nace must be regulated so that the differential pressures

in both directions will not exceed 10 mbar (Assembly as

shown in Fig. 10).

Starting from the basic adjustment set the two Vacuum

Switches by turning the adjusting screw (6/2) clockwise

so that at a pressure of 10 mbar in the reference cham-

ber against the pressure in the sensing chamber the

switch contact opens by flexing of the diaphragm. Con-

trol venting valves and pump valves each via the break

18

18

tina42e1 (2005-03) VSC150.ga

tina42e1 (2005-03) VSC150.ga

max. turning the adjusting screw (6/2) clockwise.

2.5.4 Automatic Venting of a Vacuum Chamber

to a Slight Overpressure

Assembly as in Fig. 9.

Loop the control circuit of the venting valve via the break

contact of the switching amplifier relay, terminals 12 and

13 (see Fig. 5). The switching pressure can be raised by

20 mbar max. above atmospheric pressure by turning

the adjusting screw (6/2) clockwise.

2.5.5 Differential Pressure Monitoring, Positive

and Negative Going

In an annealing plant with „holding vacuum“ pump down

and venting of the annealing pot and the vacuum fur-

nace must be regulated so that the differential pressures

in both directions will not exceed 10 mbar (Assembly as

shown in Fig. 10).

Starting from the basic adjustment set the two Vacuum

Switches by turning the adjusting screw (6/2) clockwise

so that at a pressure of 10 mbar in the reference cham-

ber against the pressure in the sensing chamber the

switch contact opens by flexing of the diaphragm. Con-

trol venting valves and pump valves each via the break

SV

SV

VSC 150

R

VSC 150

M

R

M

Oven

Crucible

Fig. 10

Differential pressure monitoring, positive and

negative going

VSC 150

M

R

SV

Fig. 9

Automatic venting between atmospheric pressure

and + 20 mbar

SV

SV

VSC 150

R

VSC 150

M

R

M

Oven

Crucible

Fig. 10

Differential pressure monitoring, positive and

negative going

VSC 150

M

R

SV

Fig. 9

Automatic venting between atmospheric pressure

and + 20 mbar