INCRA Table Saw Systems Addendum User Manual

INCRA Hardware

w w w. i n c r a . c o m

®

Manufactured by:

Taylor Design Group, Inc.

P.O. BOX 810262 Dallas, TX 75381

www.incra.com

INCRA Tools are protected by one or more of the following US patents:

#4,793,604, #4,930,221, #5,195,730, #5,275,074, #5,423,360, #5,716,045, #6,237,457,

#6,557,601, #6,672,190. Other patents granted or pending. rev.11.03.10

INCRA is a Registered Trademark of Taylor Design Group

©2009 Taylor Design Group, Inc.

Side Winder Side Crank Installation on

INCRA Table Saw Systems

Note: This addendum replaces Fig/Step 10 & Fig/Step

11 of the Woodpecker provided mounting instructions.

Please follow all assembly instructions of the original

manual up to Fig/Step 10 before using this addendum.

MADE IN THE

USA

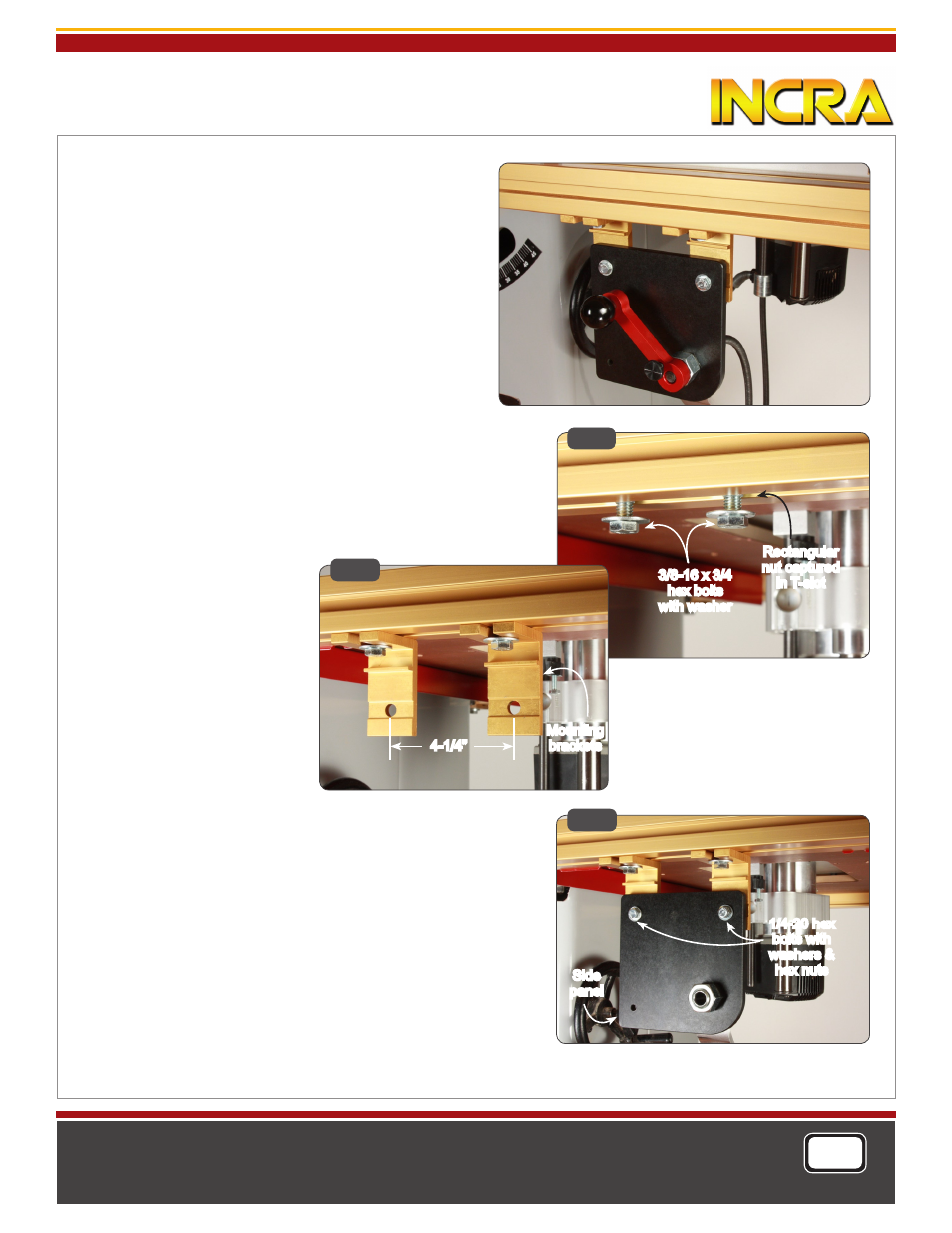

Add a large flat washer to each of the 3/8-16 x 3/4” hex bolts and

thread a 3/8-16 rectangular nut onto the end of each bolt.

Slide the rectangular nut on each of the bolt assemblies into the

T-slot located on the underside of your INCRA TS System’s front

rail and position the bolts close to your router,

Fig. 1. (You’ll be

able to adjust the final position after full assembly.)

Slide the slotted end on each

of the mounting brackets all the

way onto the bolts as shown

in

Fig. 2 then position the

brackets so that the 2 holes

are approximately 4- 1/4” apart.

Finger tighten the 2 bolts.

Attach the Side Winder Crank’s

side panel to the brackets using

(2) 1/4-20 x 1-1/2” hex bolts with

washers and hex nuts,

Fig. 3.

Be sure to place a split lock washer on the end of the bolt before

threading on and tightening the hex nuts. Tighten the (2) 3/8-16

hex bolts that secure the brackets to the underside of the rails.

Continue with Fig/Step 12 in the Side Winder Owner’s Manual.

TIP: Moving the bracket/crank assembly to the left or right along

the rail can improve how easily you are able to rotate the crank

handle. After you have attached the flex shaft to your router,

try sliding the bracket/crank assembly to different positions left

or right to find the easiest crank rotation. In general, the more

relaxed the lower loop or “U-turn” is on the flex shaft, the easier

the crank will rotate.

Fig.1

Fig.2

Rectangular

nut captured

in T-slot

Mounting

brackets

4-1/4”

Side

panel

Fig.3

3/8-16 x 3/4

hex bolts

with washer

1/4-20 hex

bolts with

washers &

hex nuts