Step 3 wiring, Mcdonnell & miller, Ps-800 series – Hydrolevel VXT-120 V2 User Manual

Page 2: Safgard model oem-170td, Float style control, Honeywell model rw-700 guard ring

Step 3

Wiring

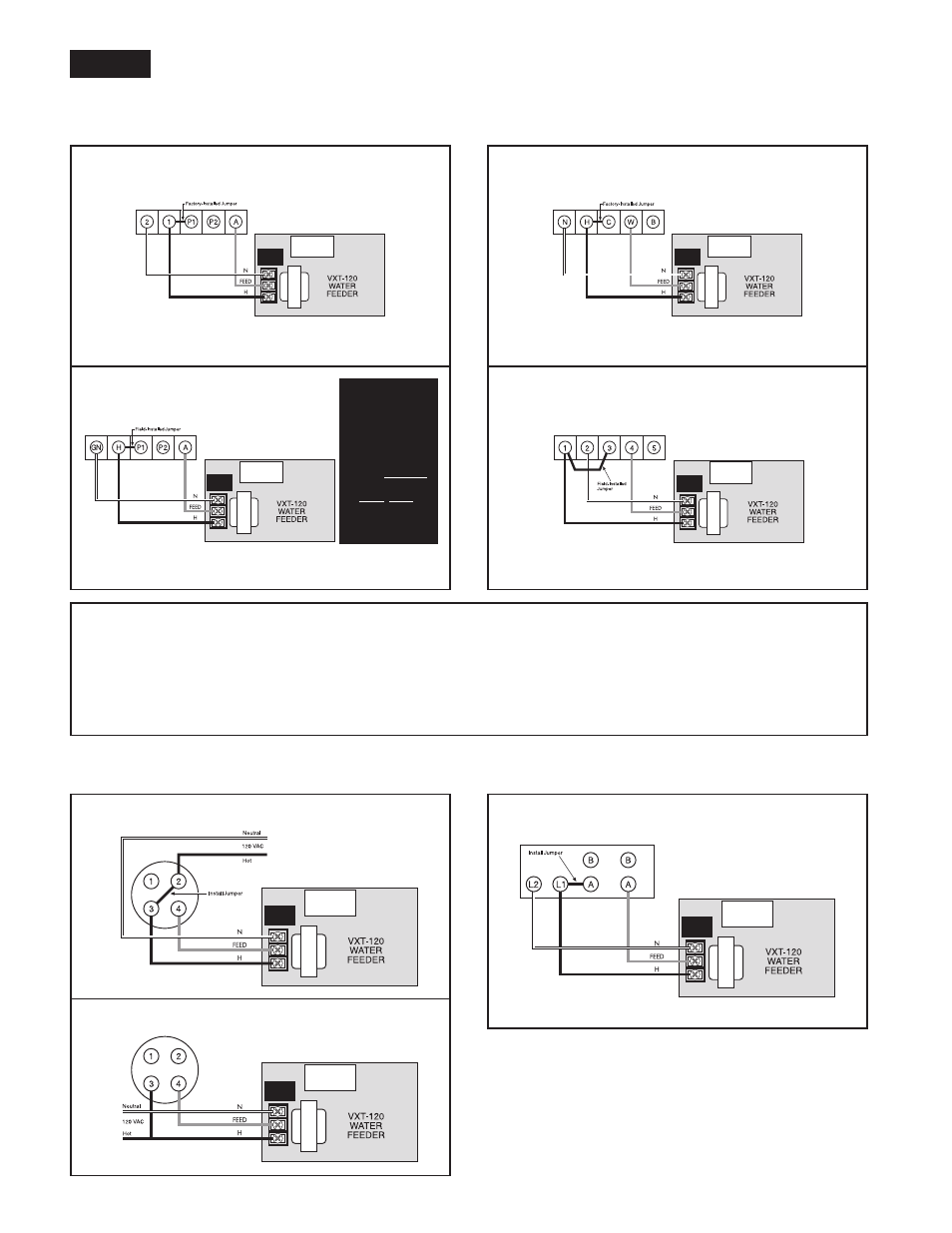

Select the wiring diagram below that corresponds to the low water cut-off installed on the boiler. Consult boiler manufacturerʼs

instructions for proper burner terminal connections.

McDonnell & Miller

Note:

If there is no jumper installed on the low water cut-off

between 1 and P1, see ALTERNATE WIRING box.

Note:

If there is no jumper installed on the low water cut-off

between H and C, see ALTERNATE WIRING box.

Note:

If there is no jumper installed on the low water cut-off

between H and P1, see ALTERNATE WIRING box.

Note:

If there is no jumper installed on the low water cut-off

between 1 and 3, see ALTERNATE WIRING box.

Hydrolevel

Safgard Model 450 / CycleGard CG450

STANDARD WIRING

PS-800 Series

– Newer Models

STANDARD WIRING

PS-800 Series

– Older Models

STANDARD WIRING

Safgard Model OEM-170TD

STANDARD WIRING

IMPORTANT

To prevent over-

feeding and possible

flooding, when used

with the OEM-170TD,

the VXT should be

set with a Feed

Delay of 10 minutes

and a Feed Amount

of 1 to 5 gallons

(see step 5).

DO NOT USE LWCO

SETTING.

Float Style Control

Using the burner circuit to power the feeder

Safgard & CycleGard Models:

If there is no jumper installed between terminals 1 and P1 on the low cut-off

(between H and P1 on Model OEM-170TD), then the cut-off is powered by a

separate power source from the burner circuit and the following wiring must

be used:

Connect a wire from the FEED terminal on the feeder to the A ter-

minal on the cut-off.

Connect a wire from terminal H on the feeder to the

burner circuit hot.

Connect a wire from terminal N on the feeder to burner

circuit neutral.

PS-800 Series:

If there is no jumper installed between terminals H and C on the low water cut-

off (terminals 1 and 3 on older models), then the cut-off is powered by a sep-

arate power source from the burner circuit and the following wiring must be

used:

Connect a wire from the FEED terminal on the feeder to the W (4 on

older models) terminal on the cut-off.

Connect a wire from terminal H on

the feeder to the burner circuit hot.

Connect a wire from terminal N on the

feeder to burner circuit neutral.

Using a separate power source for the feeder

ALTERNATE WIRING

Honeywell

Model RW-700 Guard Ring