Enhanced intermittent level test feature, Hi temp lock-out, 3operating instructions – Hydrolevel CG470 Series User Manual

Page 3

OPERATING TEST PROCEDURE

1. After installation, bring the boiler water to

a safe operating level, turn on power and

set the thermostat to call for heat. The

amber LED lamp should be off. The boiler

will fire immediately.

2. Slowly lower the boiler water to a point

below the probe. The amber LED lamp on

the control will light. The lamp may begin

to flicker with the bouncing water level.

Stop draining the boiler when the lamp

glows steadily. NOTE: The water should

not be lowered beyond a visible point in

the gauge glass.

3. The boiler will shut down within 15

seconds.

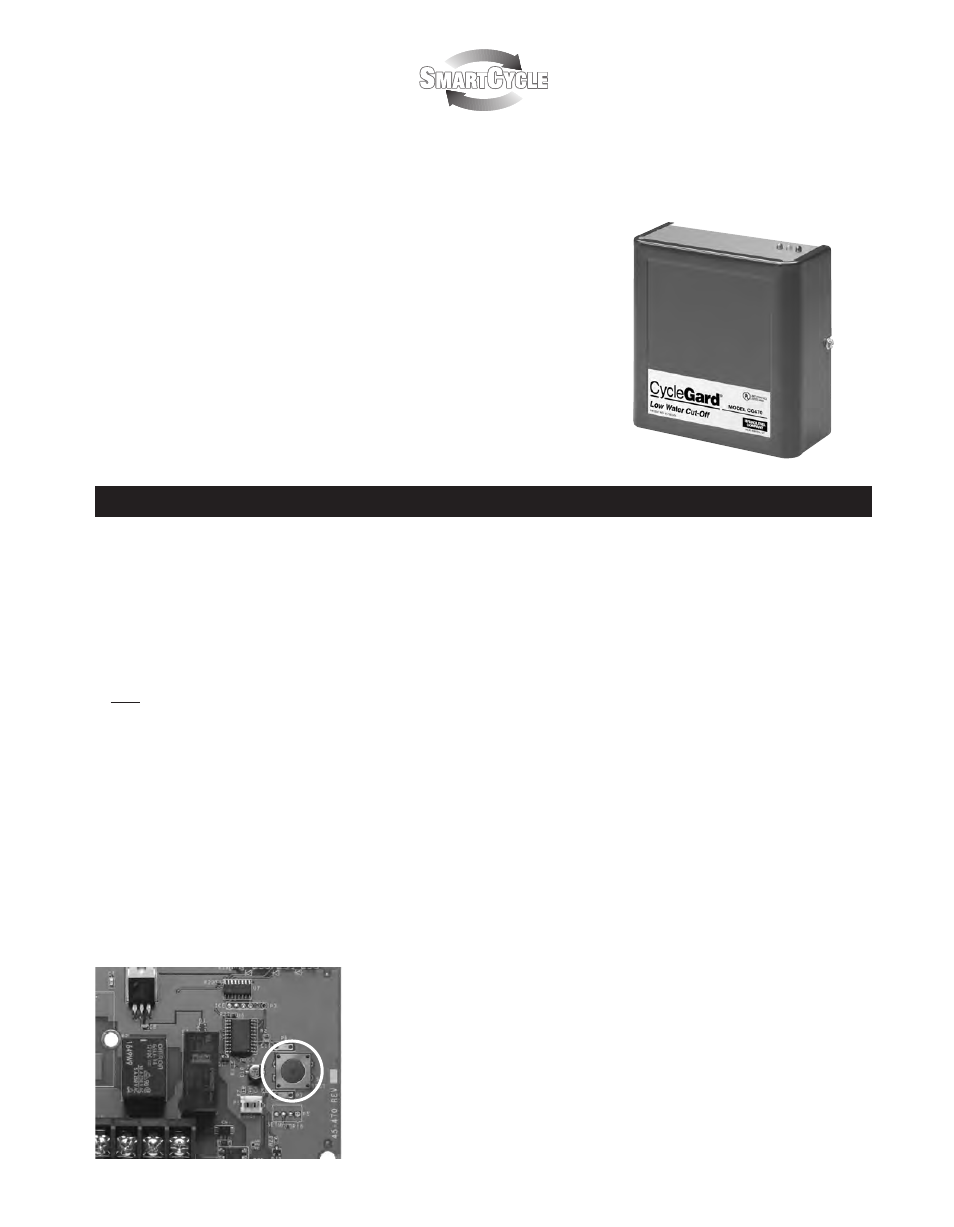

TEST BUTTON

The CG470 is equipped with a button to test

wiring and control operation. To use the test

button, remove the cover and press the but-

ton located on the circuit board. The burner

will shut off for the length of time the button

is pressed. If the burner does not shut off,

remove power and recheck wiring. Note:

Hydrolevel recommends lowering the water

level (as described in “Operating Test

Procedure”) to functionally test the control

and probe operation on an annual basis.

IF BURNER DOES NOT SHUT DOWN IN

LOW WATER

1. Check terminal block wiring to insure that

all connections are correct.

2. Check the probe installation to insure that

there is 1/4" clearance from any surface

within the boiler or pipe. (Refer to Step 1

on page 1 of this instruction sheet.

3. Clean the boiler in accordance with the

manufacturer’s instructions. Machining

oils, grease, rust and other contaminants

in the boiler water can cause foaming or

surging and make a low water condition

difficult to detect during burner operation.

IF THE AMBER LED LAMP IS ON

The amber LED lamp indicates that the water

is below the probe. If the gauge glass shows

that the water is at the correct operating level

and the amber LED is lit, check the following:

1. Check for plugged gauge glass.

2. Make sure probe lead wire is properly

secured to the terminal.

3. Check for proper ground between probe

and boiler shell. Excessive use of Teflon

tape or sealing compound may isolate the

probe from the boiler shell.

4. Remove probe and examine for oily

residue. Clean probe with steel wool and

skim boiler.

IF THE RED LED LAMP IS ON

The red LED lamp indicates that the boiler

has experienced an unsafe temperature

(250°F). The control will lock out the burner

circuit and illuminate the LED when this

occurs. DANGER: Adding water to an over-

heated boiler can cause an explosion. The

boiler must be allowed to fully cool before

adding water. The boiler should be evaluated

by a qualified service technician before

restoring operation. The CycleGard control

should be replaced.

IF THE RED LED LAMP IS BLINKING

A blinking red LED lamp indicates that the

control has been locked out on an unsafe

temperature at some point in its history. The

CycleGard control should be replaced.

IF THE GREEN LED LAMP IS ON

The green LED lamp indicates that the control

is conducting an Intermittent Level Test. The

burner does not fire during the test period.

See Intermittent Level Test Feature on this

page for more details.

Enhanced Intermittent

Level Test Feature

To provide added protection to today’s small-

er boilers, CycleGard Model CG470 is

equipped with an enhanced Intermittent Level

Test (ILT) feature. Fifteen minutes after the

boiler reaches boiling temperature, the ILT

feature removes power from the burner for

60 seconds. During this ILT test, foam dissi-

pates and the water level quickly stabilizes,

allowing the CG470 to monitor the true water

level in the boiler. If the water in the boiler is

at a safe level, the control will re-energize the

burner. If the water level has dropped to a

level below the probe, the control will keep

the burner off (and send power to an optional

water feeder) until the water level is replen-

ished. The 60 second ILT test will repeat

every 15 minutes as long as the boiler

remains at boiling temperature. The ILT fea-

ture disengages when the boiler temperature

is below the boiling point.

The optional Smart Cycle feature is designed to

prevent unnecessary ILT tests in the event the

burner cycles off for other reasons (ex. pres-

sure limit or thermostat calls). When activated

(see wiring on previous page), the Smart Cycle

feature restarts the 15 minute timing sequence

each time the burner fires. So, for example, if

the pressure control shuts down the burner,

the Smart Cycle feature will reset the 15

minute clock once the pressure control re-

energizes the burner. This prevents an ILT

from occurring sooner than is needed as the

control was able to monitor the settled water

level during the pressure limit interruption.

Hi Temp Lock-Out

Unlike any other steam low water cut-off, the

CG470 monitors boiler temperature in addi-

tion to water level. This feature will shut

down and lock out the burner circuit if the

boiler reaches an unsafe level (250°F).

3

OPERATING INSTRUCTIONS

NOTE:

For proper low water cut-off operation, the boiler should be cleaned at initial installation and periodically thereafter. Refer to the boiler

manufacturer’s instructions for cleaning procedures.