Flint & Walling Commander Pro 100 User Manual

Page 5

Flint & Walling, Inc. • 95 North Oak Street • Kendallville, IN 46755 • www.flintandwalling.com

© Copyright 2008 Flint & Walling, Inc. All rights reserved.

5

1.

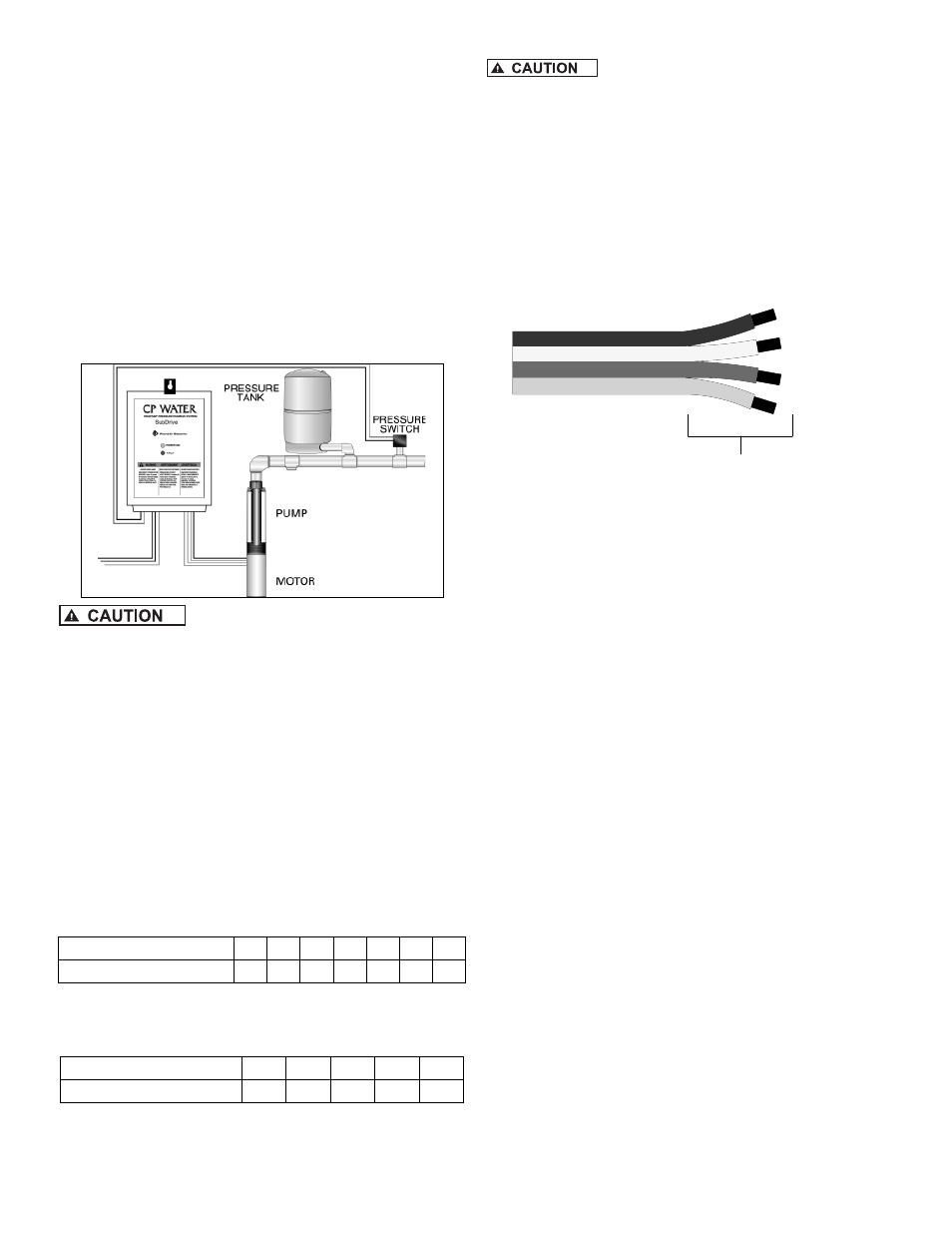

A tank tee is recommended for mounting the tank,

pressure sensor, pressure gauge, and pressure relief

valve at one junction. If a tank tee is not used, the

pressure sensor should relocated within 6 ft. (1.8

meters) of the pressure tank to minimize pressure

fluctuations. There should be no elbows between the

tank and pressure sensor.

2.

The unit should be mounted on a sturdy supporting

structure such as a wall or supporting post -

please account for the fact that the unit weighs

approximately 17 lbs. for NEMA 1 models and 22.0

lbs. for NEMA 4 models.

3.

The electronics inside the CP WATER SD100 are air-

cooled. As a result, there should be at least 6 inches

of clearance on each side and below the unit to allow

room for air flow.

There should be at least 6 inches of

clearance on each side and below the unit to allow

room for proper air flow. There are to be no elbows

between the tank and pressure switch.

4.

The CP WATER SD 100 should only be mounted

with the wiring end oriented downward. The controller

should not be placed in direct sunlight or other

locations subject to extreme temperatures or humidity

(mounting location should not be subjected to

freezing conditions or condensation).

5.

The mounting location should have access to 230V

electrical supply and to the submersible motor wiring.

WIRE SIZING

Maximum wire lengths connecting the CP100 controller

to the main circuit box. (Based on 3% voltage drop at

230V)

Copper Wire Size (AWG)

12*

10

8

6

4

3

2

Maximum Length (Feet)

85

140 220 345 550 680 895

*Wire with 90° C insulation only.

Maximum wire lengths connecting the motor to

the CP100 controller

Copper Wire Size (AWG)

14

12

10

8

6

Maximum Length (Feet)

320

510

810

1280

2010

Due to the inherent voltage changing

characteristics of variable frequency drives (VFD), there

is additional stress placed on the insulation of the wire

between the controller and the motor compared to a

standard pump system. Extra care must be taken when

using Unjacketed Flat Parallel Pump Cable to ensure that

the insulation on each of the separated wires is the same

thickness. Care must also be taken to ensure a proper

seal with shrink tubing on any splices. Failure to take

these precautions can lead to “wire burn through” that will

shut down the system. Under these circumstances, no

permanent damage usually occurs to the controller or motor.

For further details call Technical Support at

1-800-742-5040.

SEPARATED WIRE

IL0837

1. NOTE: DO NOT USE ALUMINUM WIRE.

2. Use 20 Amp circuit breaker for 230V supply

Controller Installation Procedure - SD100

1. Disconnect electrical power at the main breaker

2.

Drain the system (if applicable)

3.

Install pressure sensor - the pressure sensor has a

1/4 - 18 National Pipe Thread (NPT) connection.

4.

Remove the CP WATER SD100 cover by removing

the three lid screws. Install the unit to the wall using

three mounting screws (not included).

Wiring Connections

1.

Verify that the power has been shut off at the main

breaker.

2.

Verify that the dedicated branch circuit for the CP

WATER SD100 is equipped with a 20 AMP circuit

breaker.

3.

Remove the CP WATER SD100 lid.

4.

Feed the motor leads through the opening on the

bottom right side of the unit and connect them to the

terminal block positions marked (green ground wire),

Red (Black) Yellow (Brown) and Black (Blue)

5.

Feed the 230V power leads through the larger

opening on the bottom left side of the CP WATER

SD100 controller and connect them to the terminals

marked L1, GND, and L2 .

6.

Feed the pressure sensor leads through the smaller

opening on the bottom left side of the CP WATER

SD100 unit and connect the red and black leads to

the terminals marked “1” and “2” (interchangeable)

with a small screwdriver (provided).

7.

Use the appropriate strain relief or conduit

connectors.