Flint & Walling SPJ User Manual

Page 2

2

© Copyright 2012. All rights reserved.

PIPING

1. Plastic or galvanized steel pipe may be used

in the installation. Plastic pipe must have a

minimum pressure rating 160 P.S.I. Galvanized

steel pipe must be in good condition free of rust

and scale. Threads should be sharp, cleanly

cut.

2. Both the suction and discharge pipe should be

no smaller than the corresponding tappings

of the pump (See Figure 1). If long runs are

encountered larger pipe should be used.

Smaller pipe will reduce the capacity of the

pump.

3. All joints and connections should have pipe

sealing compound (male threads only) applied

and drawn up tightly.

CAUTION: The entire system must be air and water

tight for efficient operation.

PUMP INSTALLATION

1. Refer to Figures 3, 4, 5, and 6 for typical

installations. If galvanized pipe is used, both the

suction and discharge pipe should be supported

at a point near the pump to avoid strains being

placed on the pump.

2. The suction pipe should slope upwards from the

water source to the pump. Locate the pump

as close to the water as possible keeping the

suction pipe as short as conditions permit.

3 Avoid dips or pockets in offset piping or air

will accumulate at high points which will make

priming difficult.

4. A foot valve located in the water or a check

valve located as close to the water as possible

will reduce priming time of the pump and help

maintain prime. A strainer must be used on the

suction line to filter out dirt and debris.

5. Install a gate valve and union in the discharge

line. For removal of the pump for service, close

the gate valve and disconnect the union.

CAUTION: Do not use a globe valve or other

restricting type of valve at the discharge. This will

seriously restrict the capacity of the pump.

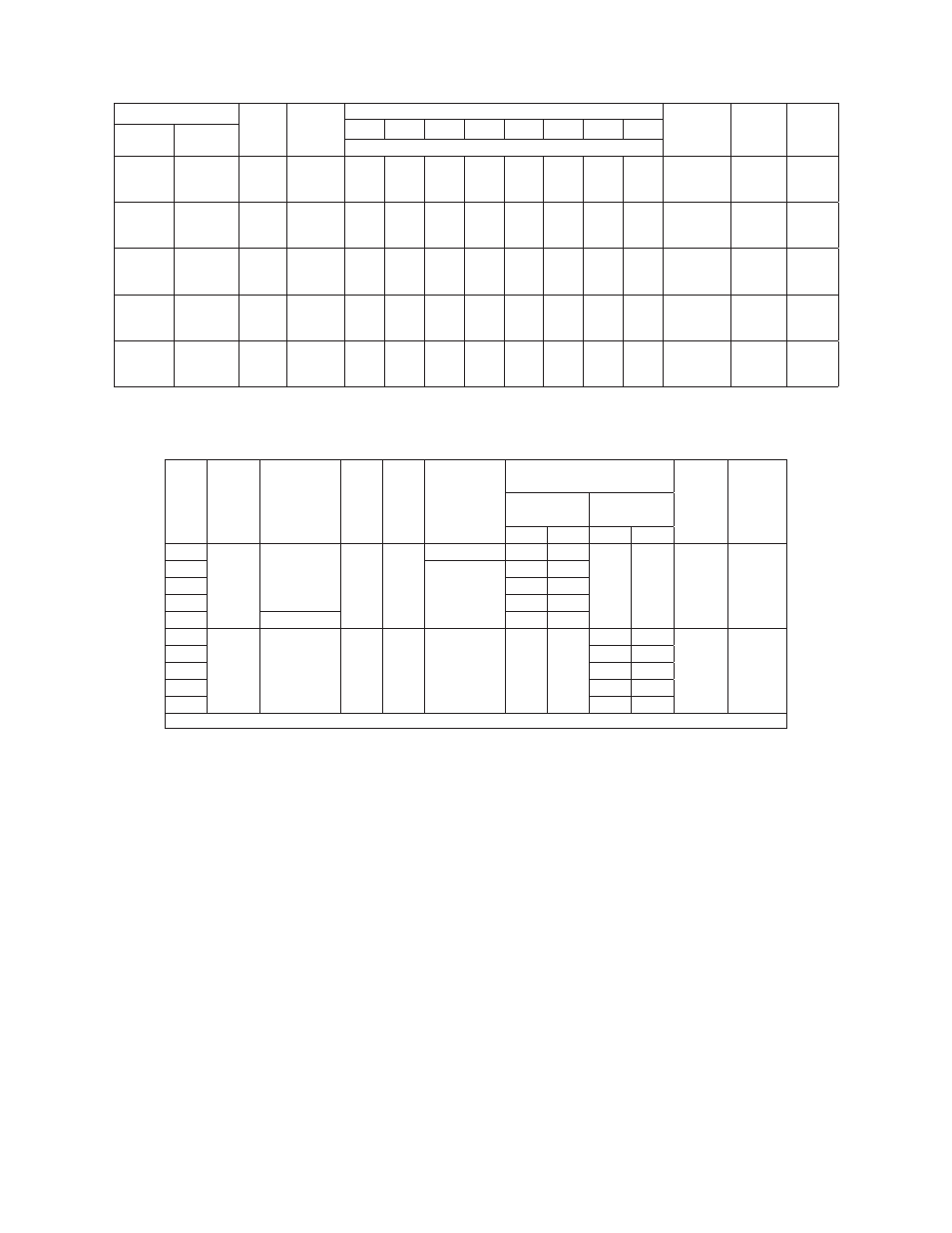

PERFORMANCE

Model Number

HP

Suction

Lift Ft.

Discharge Pressure PSI

Shut-Off

Pressure

PSI

Suction

Pipe Tap

Disch.

Pipe

Tap

10

15

20

25

30

35

40

45

1 Phase

3 Phase

Capacity - U.S. Gallons per Minute

SPJ07P1 SPJ07P3

3/4

5

15

25

56

47

43

48

42

37

42

37

31

37

29

22

29

22

10

21

12

41

37

33

2”

1-1/2”

SPJ10P1 SPJ10P3

1

5

15

25

58

53

48

53

48

44

48

45

38

43

37

33

38

31

25

32

24

14

23

12

11

48

43

39

2”

1-1/2”

SPJ15P1

SPJ15B1

SPJ15B3

1-1/2

5

15

25

78

70

47

77

68

46

74

66

45

70

62

44

62

53

42

53

43

34

43

30

30

47

41

36

2”

1-1/2”

SPJ20B1 SPJ20B3

2

5

15

25

86

76

52

84

74

51

81

72

50

77

69

47

71

64

45

62

55

42

52

43

30

40

25

50

45

40

2”

1-1/2”

SPJ30B1 SPJ30B3

3

5

15

25

88

77

54

86

76

53

85

75

52

84

74

51

80

72

50

73

65

49

64

55

45

53

43

10

54

50

45

2”

1-1/2”

Motor voltage: Single Phase: 3/4 - 2 HP - 115/230V 60Hz; Three Phase: 3/4 - 3 HP - 208-230/460V 50/60Hz

Maximum Case Pressure: 100 PSI

SPECIFICATIONS (Figure 2)

HP

Type

Volts/

Amps

Hz RPM

Motor

Voltage

(Factory)

Connected

Service Factor Motor

Amps

Max

Liquid

Temp

Max

Suction

Lift

Single

Phase

Three

Phase

115V 230V 230V 460V

3/4

Single

Ph

115/230

60

3450

115V

14.0

7.0

-

-

180˚F

25 Ft.

1

230V

18.0

9.0

1-1/2

21.0 10.5

2

25.0 12.5

3

230

-

13.5

34

Three

Ph

20/-230/460 60/50 3450/

2850

230V

-

-

3.5

1.75

180˚F

25 Ft.

1

4.5

2.25

1-1/2

5.7

2.85

2

7.4

3.70

3

9.8

4.90

Suction lift varies, depending upon elevation (altitude) and water temperatures.