10 fault clearance, 11 technical data – Festo DRRD-08/10 User Manual

Page 4

10

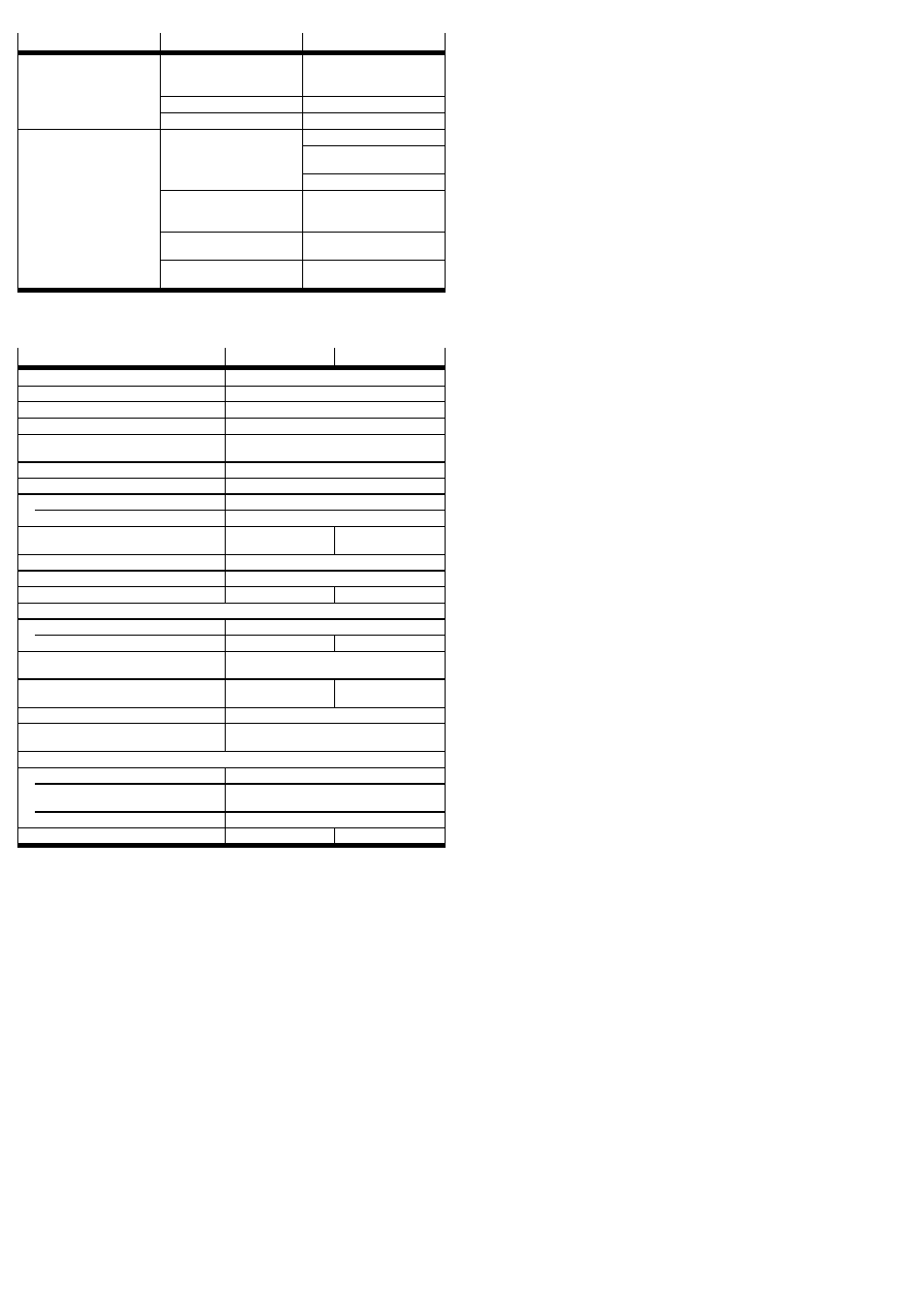

Fault clearance

Malfunction

Possible cause

Remedy

Uneven movement of the

payload

Flow control valves inserted

incorrectly

Check the flow control

function (supply or exhaust air

flow control)

Asymmetric angle setting

Symmetric setting preferred

DRRD defective

Return to Festo

Hard metal impact at the end

position

Flanged shaft does not remain

in the end position

(rebounding)

Residual energy too high

Select a lower swivel speed

Move only against residual air

cushion on the exhaust side

Select a lighter load

Semi-rotary drive moves

against an unpressurized

chamber

Pressurize semi-rotary drive

on both sides

Shock absorber unscrewed

too far

Observe the maximum

permissible unscrewing length

Cushioning component

defective/worn

Replace cushioning component

(

8 Disassembly and repair)

Fig. 18

11

Technical data

Size

8

10

Design

Semi-rotary drive with twin pistons

Cushioning

Elastic cushioning rings/plates at both ends

Pneumatic port

M3

Operating medium

Compressed air to ISO 8573-1:2010 [7:4:4]

Note on the operating medium

Lubricated operation possible (in which case

lubricated operation will always be required)

Operating pressure

[bar]

3 … 8

Mounting position

any

Swivel angle

[°]

180

Setting range on both sides

[°]

infinitely adjustable between –100 … +10

Cushioning angle (

Z minimum swivel

angle)

[°]

38

37

Repetition accuracy

[°]

≤ 0.03

Ambient temperature

[°C]

–10 … +60

Theoretical torque at 6 bar

[Nm]

0.2

0.4

Max. axial load (static)

Tension

[kN]

0.26

Pressure

[kN]

0.7

1.1

Max. permissible axial and radial

force on flanged shaft

dependent on the distance of the force

application point (

www.festo.com/catalogue)

Max. permissible mass moment of

inertia

[kgcm

2

] 15

20

End-position adjustment

by turning the cushioning components

Note on materials

Contains paint-wetting impairment substances

(PWIS)

Materials

Housing

Anodised aluminum

Flanged shaft, plug, shock absorber

retaining plate, screws

Steel

Seals

TPE-U (PU), NBR

Product weight

[kg]

0.16

0.25

Fig. 19