2 pneumatic installation, 3 electrical installation, 5 commissioning – Festo DRRD-08/10 User Manual

Page 2: 1 commissioning end-position adjustment

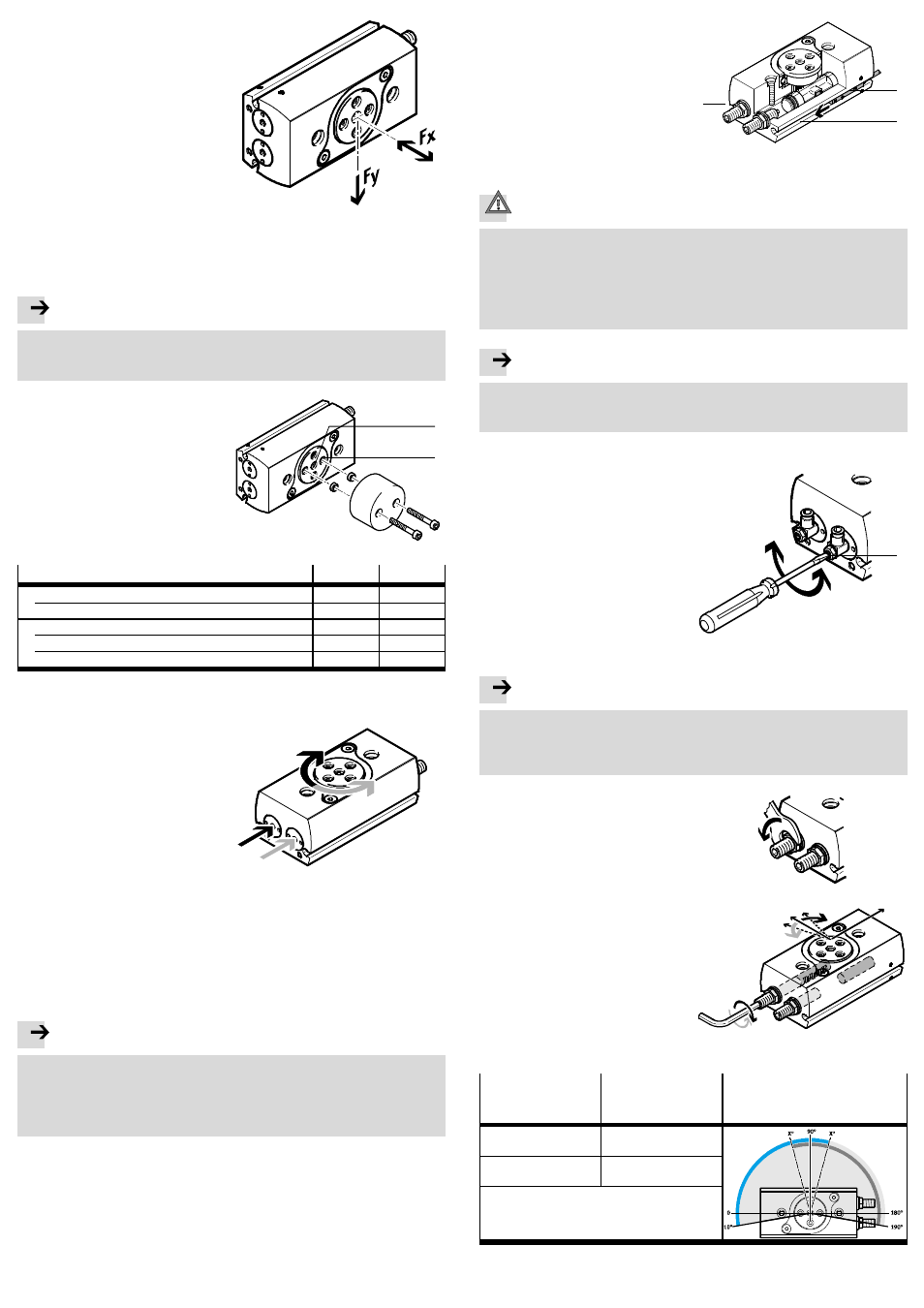

3. Pull tubing and cables through the

hollow flanged shaft, if necessary.

Diameter for wiring (

Fig. 6).

4. When mounting the payload, ob-

serve the following specifications:

– installation without tilting

– permissible radial force Fy

– permissible axial force Fx

– permissible mass moment of

inertia

– a structure that is as rotationally

symmetrical as possible.

Fig. 4

The mass moment of inertia of the payload should be calculated. Lever arms,

cantilevers and masses should be considered in the calculation (maximum per-

missible values

www.festo.com/catalogue).

Note

If there are demanding requirements for concentricity of the components on the

flanged shaft:

• Use the middle centring hole

4 as well as one of the 4 existing centring holes.

5. Secure the payload to the drive

flange at the mounting interface

5

by using at least two screws posi-

tioned opposite one another and

centring sleeves.

Observe the tightening torque

(

Fig. 6).

Fig. 5

5

4

Size

8

10

Shaft opening

4

[mm]

∅ 3

∅ 3

Centring sleeve ZBH for middle centring hole

[mm]

5

5

Screw for thread at

5

M3

M3

Centring sleeve ZBH

[mm]

5

5

Tightening torque

[Nm]

1.2

1.2

Fig. 6

4.2 Pneumatic installation

• If necessary, remove the covers in the

pneumatic ports.

To adjust the swivel speed:

• Use the GRLA one-way flow control

valves.

These are screwed directly into the

compressed air supply ports.

Fig. 7

For vertical installation and eccentric loads:

• Use the controlled check valve HGL or a compressed air spacer compensation

reservoir VZS.

In this way you can prevent the effective load from sliding down suddenly if

there is a sudden pressure drop.

4.3 Electrical installation

Note

Multiple switching cycles of proximity sensors are possible, dependent on the

design.

• Make sure the proximity sensors are always set to the first switching point.

To do this, push the cylinder switch (A

Fig. 8) in from the slot end where the

piston to be sensed is located until the first switching occurs.

• Place the proximity sensors for

sensing the end positions into the

slots

7.

Fig. 8

7

(A)

7

5

Commissioning

Caution

Danger of injury from rotating loads.

• Make sure the DRRD is only set into motion with protective devices.

• Make sure that in the swivel angle of the DRRD

– nobody can reach in

– no foreign objects can enter

(e.g. by means of an individual protective guard).

Note

• Comply with the following prerequisites:

– the shock absorbers are secured with lock nuts

– the operating conditions are within the permissible ranges.

5.1 Commissioning end-position adjustment

1. Rotate both upstream one-way flow

control valves (B):

– at first completely closed

– then open them again

approximately one turn.

2. Pressurize the drive optionally in one

of the following ways:

– slow pressurisation of one side

– simultaneous pressurisation of

both sides with subsequent

exhausting of one side.

(B)

Fig. 9

Note

Risk of damage!

If the shock absorber is unscrewed too far, it will result in the piston colliding

with the end cap with insufficient cushioning.

• Observe the permissible shock absorber settings (

Fig. 13).

3. Pressurize the corresponding port to

swivel the DRRD into the desired end

position.

4. Loosen the lock nut on the shock

absorber.

Fig. 10

5. Turn the corresponding shock

absorber until the desired end

position adjustment has been

reached.

Fig. 11

Angle setting

Reaction

Setting range related to the

basic factory setting (example

DRRD-...-180)

Turn the shock absorber

clockwise

Reduce the swivel angle

Turn the shock absorber

anti-clockwise

Increase the swivel angle

Fig. 12