Operating instructions position switch ng, Electrical connection, Correct use – EUCHNER NGxxx User Manual

Page 3: Incorrect use, Mounting, Setup, Service and inspection, Technical data

Operating Instructions Position Switch NG...

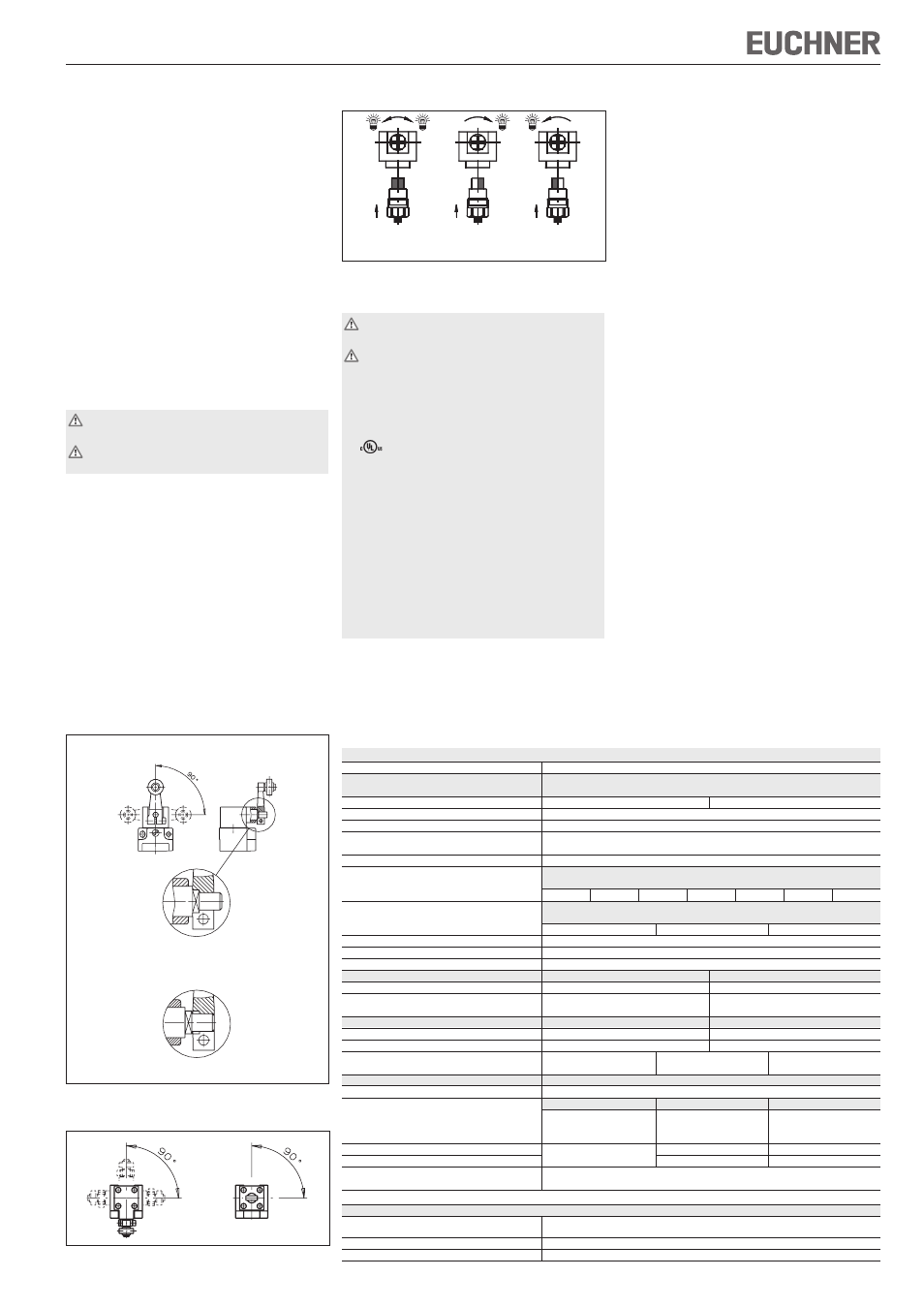

Switching direction change with lever arm actuation

Figure 3: Changing the switching direction

Electrical connection

Electrical connection must be performed only

by authorized personnel.

When choosing the insulation material and wire

for the connections, pay attention to the over-

temperature in the housing (depending on the

operating conditions)!

For NG2:

For use and applications as per the requirements

of

, a class 2 power supply or a class 2

transformer according to UL1310 or UL1585 must

be used.

Connection leads of position switches installed at

the application site must be separated from all

movable and permanently installed leads and non-

insulated active parts of other installation parts which

operate with a voltage of over 150 V, in such a way

that a constant clearance of 50.8 mm is observed.

This does not apply if the movable leads are equipped

with suitable insulation materials which possess an

identical voltage stability to the other relevant

installation parts or higher.

Correct use

Position switches series NG are used for positioning

and controlling machines and in industrial

installations.

The built-in switching element with snap-action

function has an NO and an NC contact with double

gap and electrically isolated switching bridge (direct

opening travel 2 x 0.6 mm)

Correct use includes compliance with the relevant

requirements for installation and operation, in

particular

EN 60 204-1, Safety of machinery. Electrical

equipment of machines. General requirements

EN 1050, Safety of machinery. Principles for risk

assessment.

Incorrect use

Position switches with switching element ES510

(snap-action switching element not positively dri-

ven) must not be used in safety circuits.

Mounting

Mounting must be performed only by authorized

personnel.

The position switches must not be used as a

mechanical stop.

The actuator (arm) can be positively mounted to

the actuating shaft.

The square drive on the actuator and actuating shaft

must engage with each other (see Figure 1a).

Continuously adjustable fastening is possible

(interference fit, see Figure 1b).

To ensure correct operation, the trip dog must

move the actuator at least 1 mm or 5° beyond the

switching point (see Figure 4 travel diagrams).

Position switches must be attached and, if

necessary, protected in such a way that predictable

damage can be avoided.

It must be ensured that position switches are

accessible for maintenance and function tests.

Adjustment options

Vertical actuator adjustment

Figure 1: Vertical actuator adjustment

Horizontal adjustment 4 x 90°

Figure 2: Horizontal adjustment

Left / right

Right

Left

switching

switching

switching

(standard position)

Version NG1... (cable entry)

Fit cable gland M20x1.5 with appropriate degree

of protection.

Conductor cross-section 0.34 ... 1.5 mm².

For pin assignment see Figure 9.

Tighten screws for connections to the switching

element to 1 Nm.

Check that the cable entry is sealed.

Close switch cover and tighten screws to 1.2 Nm.

Version NG2... (plug connector SR6)

Conductor cross-section 0.5 ... 1.5 mm².

For pin assignment see Figure 9a.

Version NG2... (plug connector M12/SVM5)

Conductor cross-section 0.34 mm².

For pin assignment see Figure 9b.

Setup

Function test

Actuate plunger or lever arm and check the

switching function.

Service and inspection

No servicing is required, but regular inspection

of the following is necessary to ensure trouble-free

long-term operation:

correct switching function

secure mounting of components

dirt and wear

sealing of cable entry

loose cable connections or

plug connectors.

Exclusion of liability under the following

conditions:

if the unit is not used for its intended purpose

non-compliance with safety regulations

installation and electrical connection not perfor-

med by authorized personnel

failure to perform functional checks.

The year of manufacture of the switch is indicated

in the production code.

Technical data

Parameters

Value

Housing material

Anodized die-cast alloy

NG1... Cable entry

NG2... Plug connector SR6

NG2... Plug connector M12/SVM5

Degree of protection according to IEC 60529

IP 67

IP 65

Mech. operating cycles

30 x 10

6

Ambient temperature

-25...+80°C

Degree of contamination

3 (industrial)

(external, according to EN 60947-1)

Installation position

Any

Approach speed max. [m/min]

HB

HS/

VB

VS

RK

WO/

RG/RS/

SB/SM

KO/DO

RL/FO

300

60

120

30

50

10

20

Approach speed, min.

HB/HS

WO/KO/RS/

FO/VB/

RK/RG/RL/DO

VS/SB/SM

0.1 m/min

0.01 m/min

0.5 m/min

Actuation frequency

7,000 / h

(HB/HS=10,000/h; FO=6,000/h)

Actuating force at 20 °C

15 N

Contact material

Silver alloy, gold flashed

NG1...

NG2...

Connection type

Screw terminals

Plug connector

Conductor cross-section (rigid/flexible)

0.34 ... 1.5 mm²,

SR6: 0.5 ... 1.5 mm²

0.34 ... 0.75 mm² with LED indicator

NG1...M / NG2...SR6

NG2...SVM5

Rated insulation voltage

U

i

= 250 V

U

i

= 50 V

Rated impulse withstand voltage

U

imp

= 2.5 kV

U

imp

= 2.0 kV

Indicator LED

L060

L110

L220

AC/DC 12 - 60 V

AC 110 V ±15%

AC 230 V ±15%

Rated data switching element ES510

Switching principle

Snap-action contact element

Utilization category according to IEC 60947-5-1

1)

Cable entry

Plug connector SR6

1)

Plug connector SVM5

AC-12

I

e

10 A

U

e

230 V

-

-

AC-15

I

e

6 A

U

e

230 V

I

e

6 A

U

e

230 V

I

e

4 A

U

e

30 V

DC-13

I

e

6 A

U

e

24 V

I

e

6 A

U

e

24 V

I

e

4 A

U

e

24 V

Short circuit protection (control circuit fuse)

1)

see

6 A gG

4 A gG

Conventional thermal current I

th

1)

Utilization category

6 A

4 A

Switching current, min. at

10 mA

Switching voltage

24 V DC

1) Limitation for NG2... at ambient temperature > 70 ... 80 °C:

NG2...SR6

Utilization category according

AC-15

Ie 2 A

Ue 230 V

to IEC 60947-5-1

DC-13

Ie 2 A

Ue 24 V

Short circuit protection (control circuit fuse)

2 A gG

Conventional thermal current I

th

2 A

Positive mounting 4 x 90°

Continuously adjustable interference fit mounting

Figure 1a

Figure 1b