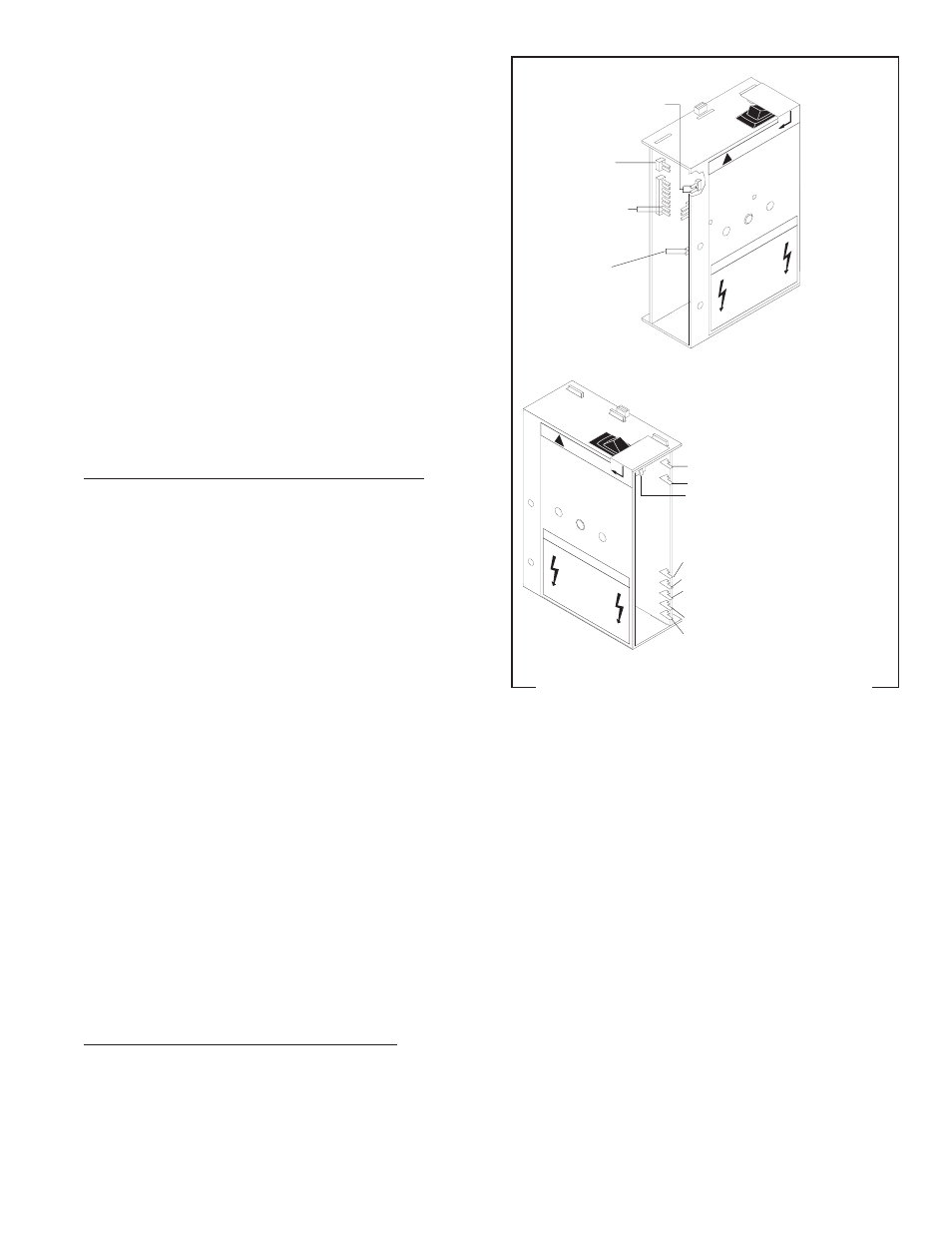

Fig. 12 electronic control board terminals – Bunn DUAL TM (Serial # DUAL010000 - Up) 27040.0000F User Manual

Page 27

Page 27

SERVICE (cont.)

ELECTRONIC CONTROL ASSEMBLY (cont.)

O

N

CAUTION

!

Failure

To Comply Voids Warrant

y!

Hot Water

Systems

– Water Tank Will F

ill

Automatically Whe

n Unit Is Connect

ed To Po

wer!

Coffee Brewers

– Fill The Water Tank In

Accordance W

ith T

he Install

ation Instructions!

DO NOT

Turn

On The Tank

Heater Switch

Until Water Comes From

Opened Faucet!

HAZ

ARD

OU

S

VO

LTA

GE

DISC

ONN

ECT F

RO

M

PO

WER

SO

URC

E

BE

FO

RE

RE

MO

VIN

G!

W

AR

NIN

G

OFF

N

O

N

CAUTION

!

Failure To Comply Vo

ids Warr

anty!

Hot Water

Systems

– Water Tank Will Fil

l

Automatically When Unit Is Conne

cted To Power!

Coff

ee Brewers –

Fill The Wate

r Tank In

Accordance With The Installat

ion Instructio

ns!

DO NOT

Turn

On The T

ank Heater

Switch

Until Water Come

s From

Opened Faucet!

HAZARDOUS

VOLTAGE

DISCONNECT FROM

POWER SOURCE

BEFORE REM

OVING!

WARNING

STOP

READ NOTICE

O

P1

P2

P3

P4

OFF

ON

ST

OP

RE

AD

N

OT

IC

E

heater terminals (5). Connect the brewer to the

power source. The indication must be:

a.) 208 volts ac for three wire 120/208 volt models

and 240 volts ac for three wire 120/240 volt

models while the red indicator on the circuit board

is on or blinking.

b.) 200 to 240 volts ac for two wire 200 or 240 volt

models while the red indicator on the circuit is on

or blinking.

14. Disconnect the brewer from the power source.

If voltage was present as described, the temperature

control of the system is operating properly. Return the

new electronic control assembly (1) and temperature

sensor (8) to Bunn-O-Matic for credit.

Electronic Controls Removal and Replacement

NOTE - each electronic control assembly is calibrated

to a temperature sensor. Both components MUST be

replaced as a set.

1. Remove all wires from the electronic control as-

sembly terminals.

2. Remove the two 8-32 screws holding the elec-

tronic control assembly to the component bracket.

3. Disconnect the temperature sensor and ready

indicator wires from the left side of the electronic

control assembly board.

4. Remove the temperature sensor from the grom-

met in the tank lid.

5. Install the new temperature sensor into the grom-

met on the tank lid. Route the wires to the location

of the new electronic control assembly.

6. Attach the temperature sensor and ready indicator

wires to the electronic control assembly.

7. Fasten the new electronic control assembly to its

bracket.

8. Reconnect the wires.

9. Refer to Fig. 12 when reconnecting the wires.

10. Review the initial set-up procedures and adjust the

control as required for the desired temperature.

Triac Assembly Removal and Replacement

NOTE - each triac installation requires the use of an

approved silicone heat sink compound. Bunn-O-

Matic recommends the use of Dow Corning 340 com-

pound or equivalent. It can be purchased direct from

Bunn-O-Matic (part number M2522.0002).

P784

1. Place the tank heater switch on the electronic

control assembly in the “OFF” position.

2. Completely drain the tank.

3. Place a stryofoam or wood block between the

center of the tank and the rear of the brewer.

4. Disconnect triac wires, white/violet from terminal

block, blue from right tank heater, blue from

electronic control and tan from tank heater switch.

5. Carefully set the brewer on its back.

6. Remove the two 2" dia. hole plugs from the bottom

cover.

7. Remove the four #10-32 keps nut securing tank to

tank mounting bracket.

8. Remove the twelve #8-32 slotted head screws

securing the bottom cover.

9. Remove the bottom cover with the four feet, the

tank mounting brackets, triac/heat sink as an

assembly.

10. Remove triac/heat sink from right tank mounting

bracket and discard.

27040 032201

FIG. 12 ELECTRONIC CONTROL BOARD

TERMINALS

GRY to GRY to

InterLock Assy

WHI & WHI to

Temperature Sensor

PNK (Top) &

GRY (Bottom) to

Interlock Assy

PNK (Top) & GRY

(Bottom) from LED

#7 BLU from Triac Assy

#6 WHI/BRN to Tank Heater Switch

TAN from Triac Assy to Tank Heater

Switch

#5 PNK to Liquid Level Probe

#4 RED to Terminal Block (Red Insert)

#3 BLK to RED Lead from Liquid Level

Switch

#2 GRN to Ground

#1 WHI/BLU to Solenoid