Operation, Warning, Caution – Enerpac WMC-Series User Manual

Page 2

OPERATION

PRELIMINARY INFORMATION: Be sure to observe safe operating procedures. Follow the warnings listed below and all

other safety information contained in this document or decals attached to cutter. Failure to do so will result in personal injury

and/or equipment damage.

WARNING

CUTTING HAZARD: Keep

hands away from cutter

blades. Only one person

should operate cutter. Do

not have one person working

near the blades while another

person controls the pump.

WARNING

Never use the cutter on

electrically active or "hot" wire

or cable. Be sure power has

been turned off before working

on electrical wire or cable.

WARNING

When working with wire rope or

cable, wrap section being cut to

prevent pieces from fl ying loose

as they are cut.

2

1. WHC and WHR models: Couple pump hose to cutter. Turn

collar on coupler fi nger tight only. No tools are needed to make

this connection.

2. Select material to be cut. When cutting short pieces of wire

rope, clamp or tape it fi rst to help prevent wires from jamming

between the blade and head.

3. Inspect blade and cutting head. Cutting case hardened steel

will dent blades and cutting heads. The blades will eventually

fatigue and crack. Replace cracked blades immediately. DO

NOT operate tool with cracked or chipped blades.

4. Unlatch cutter head.

5. Place material between blade and head shear.

6. IMPORTANT: Securely latch the cutter head.

CAUTION

Most broken blades are the result of not latching the cutter

head. When the blade is advanced, it pushes on the cutter

head. As the cutter head is pushed open, a diagonal force

causes the blade to break, and, in some cases, the cutter

head may crack.

7. On self-contained units, push release lever in toward cutter

body. For hydraulic cutterheads, close or shift valve on pump to

advance position.

8. Operate handle or pump until blade is fully advanced. DO

NOT exceed maximum cutting limits printed on tool decal.

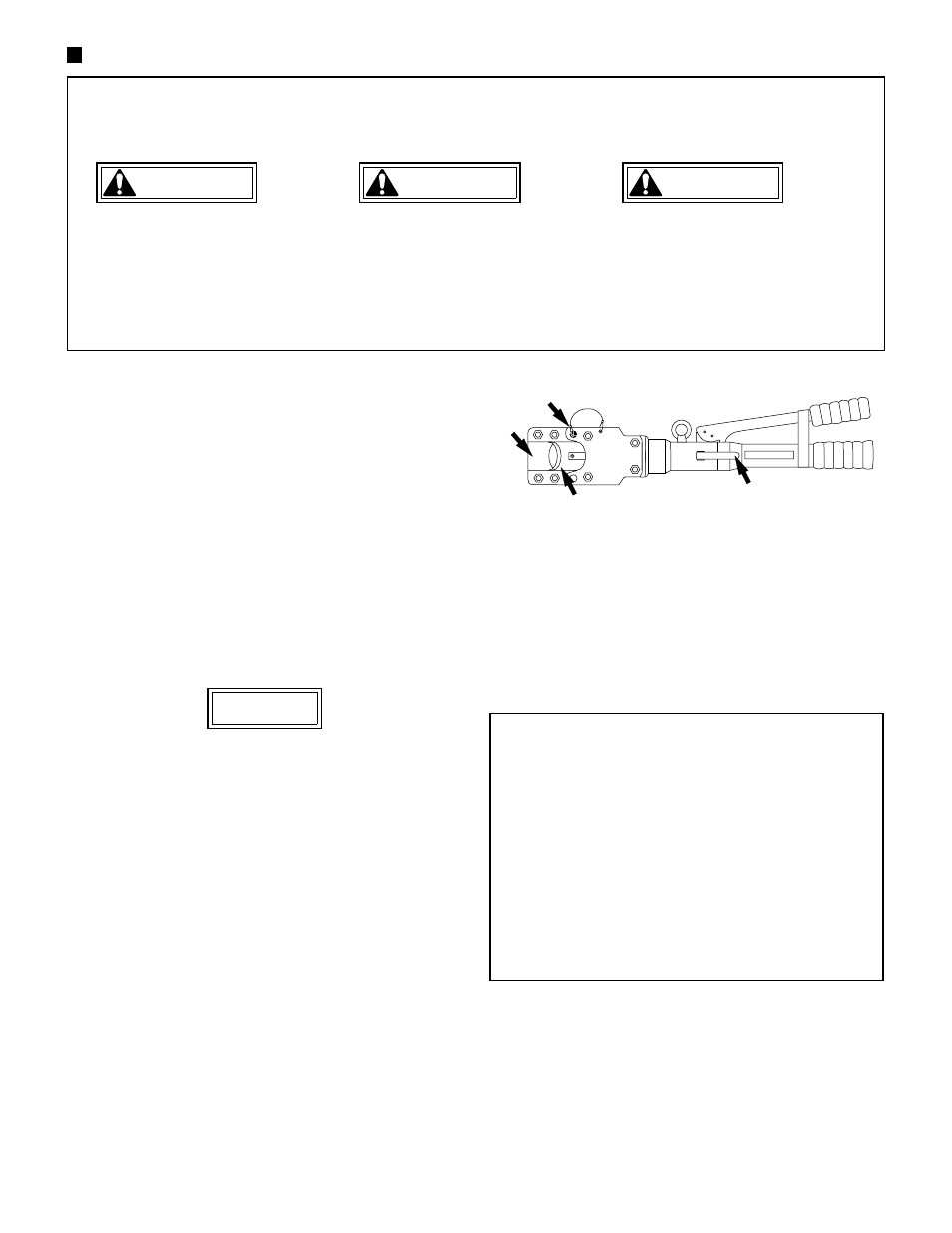

Cutter Head

Latch Pin

Release

Lever

Blade

Head

Shear

9. If the material being cut (usually wire rope or soft cables)

seems to be cut but does not break free of the tool, the blade

is hung up on something and needs to be removed. See

"Troubleshooting" on page 3.

10. Lift release lever or shift pump to release position to retract

blade. If blade does not retract, see "Troubleshooting" on

page 3.

11. Return tool to carrying case to protect from dirt and

corrosion. Always keep a spare blade on hand.

NOTE: Do not operate an empty cutter. The new blade

and cutter head shear edges will "roll" slightly with the

fi rst material cut, creating a burr. This burr falls off as

the cut takes place. Extending the blade prior to the

fi rst material cut will also raise a burr on the blade. With

no material present to knock the burr off , the blade and

head shear edges may lock together and the cutter will

not retract. To correct this situation, the blade must be

removed. Remove blade screw and blade. Unlatch cutter

head.

Use a sharpening stone to remove burr from blade. Run

the stone across the blade on the fl at side (not the knife

edge side). Keep the stone fl at and parallel to the blade.

Take care not to create a gap between the blade and

head shear.