Operation – Enerpac SC-1 User Manual

Page 3

3

Mounting Swing Clamp

Secure swing clamp to fixture using one of

the following methods:

■ Screw threaded housing into tapped hole

(1 7/8”-16 UN).

■ Bolt cylinder down using the 4 mounting

holes in the flange. Mounting holes are 0.40”

diameter.

■ Mount in a through-hole and secure with a

locknut (P/N SC1CN).

Operation

Connection for Single Acting

Connect pressure line to 1/4”-18 NPT port in

flange.

Connections for Double Acting

1. Remove plunger return spring.

2. Connect advance line to 1/4”-18NPT lower

side port or the 1/8-27NPT bottom port. If

using the bottom port, plug the lower side

port with a 1/4”-18NPT pipe plug.

Air Removal

1. Apply low hydraulic pressure (approxi-

mately 10-20 PSI) to the system.

2. Loosen plug opposite advance port slight-

ly to allow air to escape until hydraulic fluid

appears.

3. Tighten the plug to prevent further leak-

age.

WARNING

WARNING

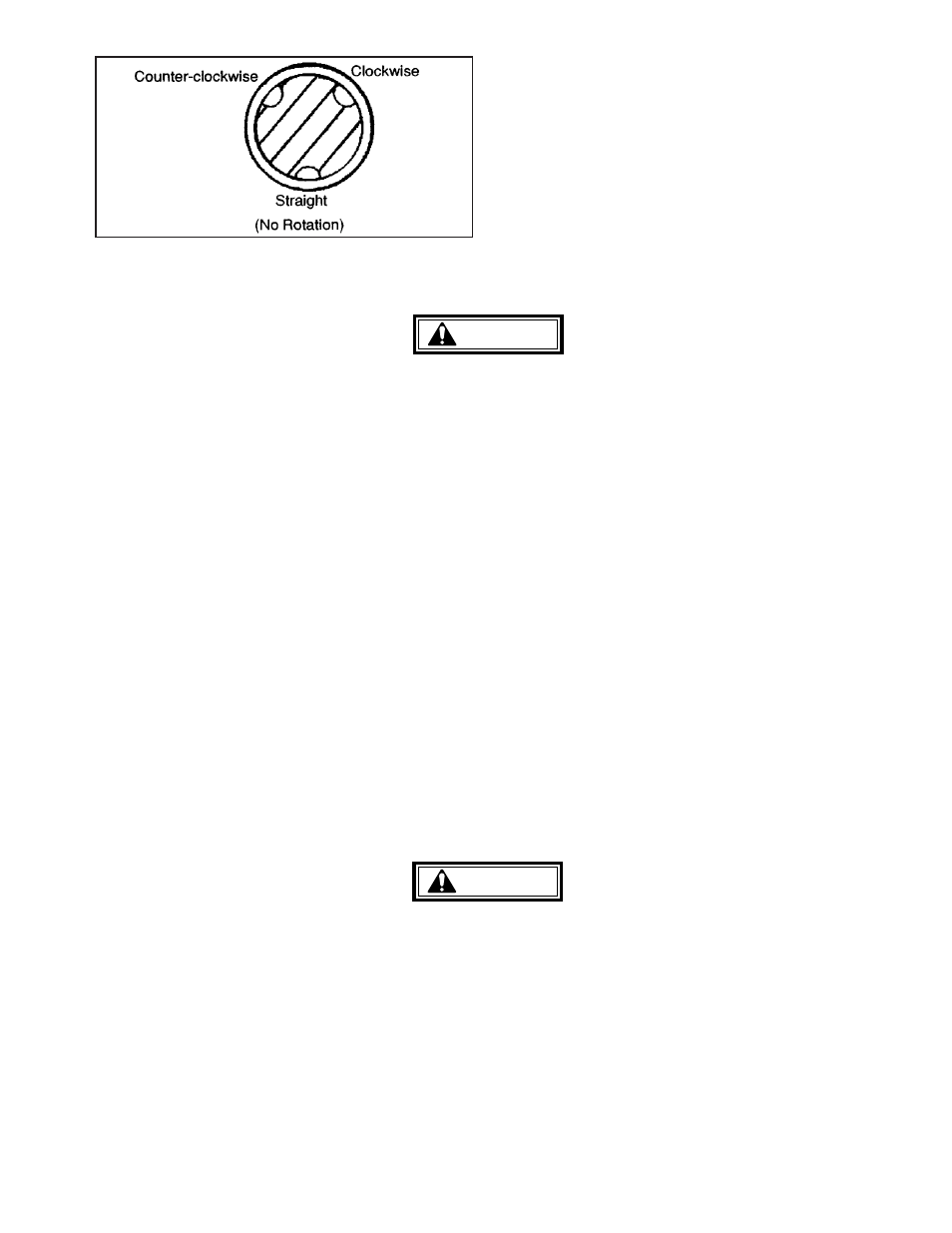

Figure 4: Plunger Rotation (Top View)

NEVER exceed maximum pressure rating of lowest rated component in your system. Maximum

pressure for SC-1 swing cylinder with standard clamp arm is 3000 PSI. When using custom

clamp arms over 4 inches long, the maximum pressure rating is LOWER. See Figure 2 for clamp

arm specifications. Exceeding rated pressure will result in component failure and may cause

equipment damage and/or personal injury.

If your swing cylinder requires repair work, contact a local ENERPAC authorized

service center.

NEVER operate a double-acting swing clamp unless BOTH ports are connected to the hydraulic

circuit. If one of the ports is left uncoupled, pressure will build up behind it when the swing

clamp is operated. This may lead to equipment damage and/or personal injury.