Enerpac CYDA-Series User Manual

Page 2

cylinder base for added stability. Do not weld or otherwise modify

the cylinder to attach a base or other support.

Avoid situations where loads are not directly centered on

the cylinder plunger. Off-center loads produce

considerable strain on cylinders and plungers. In

addition, the load may slip or fall, causing potentially dangerous

results.

Distribute the load evenly across the entire saddle

surface. Always use a saddle to protect the plunger.

IMPORTANT: Hydraulic equipment must only be serviced

by a qualified hydraulic technician. For repair service,

contact the Authorized ENERPAC Service Center in your

area. To protect your warranty, use only ENERPAC oil.

WARNING: Immediately replace worn or damaged parts

by genuine ENERPAC parts. Standard grade parts will

break causing personal injury and property damage.

ENERPAC parts are designed to fit properly and withstand high

loads.

1.0 FEATURES

1.1 At 3000 psi hydraulic pressure CYDA-15 will

provide clamping force (push) of 1230 lbs.

Retracing force (pull) at same pressure is 600

lbs.

1.2 CYDA-15 has a maximum stroke of 1.5 inches.

1.3 CYDA-15 can be operated by air or hydraulic

pressure. Air pressure shall not exceed 200 psi,

hydraulic pressure shall not exceed 3000 psi.

1.4 All pressure ports are located at one end (base).

The base can be removed and multiple cylinders

can be attached to a common manifold. See

Figure 2.

1.5 Many mounting brackets and accessories are

available for CYDA-15. Refer to Enerpac

Workholding Catalog.

2.0 INSPECTION

Upon removal from the shipping container, the unit

should be visually inspected for any shipping

damage.

3.0 INSTALLATION

3.1 Remove and discard all protective plastic caps. The unit can

be mounted on suitable Enerpac mounting brackets with other

Enerpac accessories. Mount unit on bracket.

CAUTION: DO NOT USE ALUMINUM BASE AS A

MOUNTING SURFACE.

3.3 Set operating pressure from 100-500 psi. Cycle the unit a few

times until all air is bled out from the connectors. Then tighten

connectors to prevent leakage. Reset hydraulic pressure to

normal operating setting.

4.0 PERIODIC INSPECTION AND MAINTENANCE

The CYDA-15 require maintenance only when wear or leakage is

noticed. Repair as required. Maintenance Kit CYDA-15K contains

seals and instructions for repair of this unit. Overhaul maintenance,

in most cases can be performed by the user and good results.

Occasional visual inspection should be performed to detect any

problem which would necessitate overhaul maintenance.

www.enerpac.com

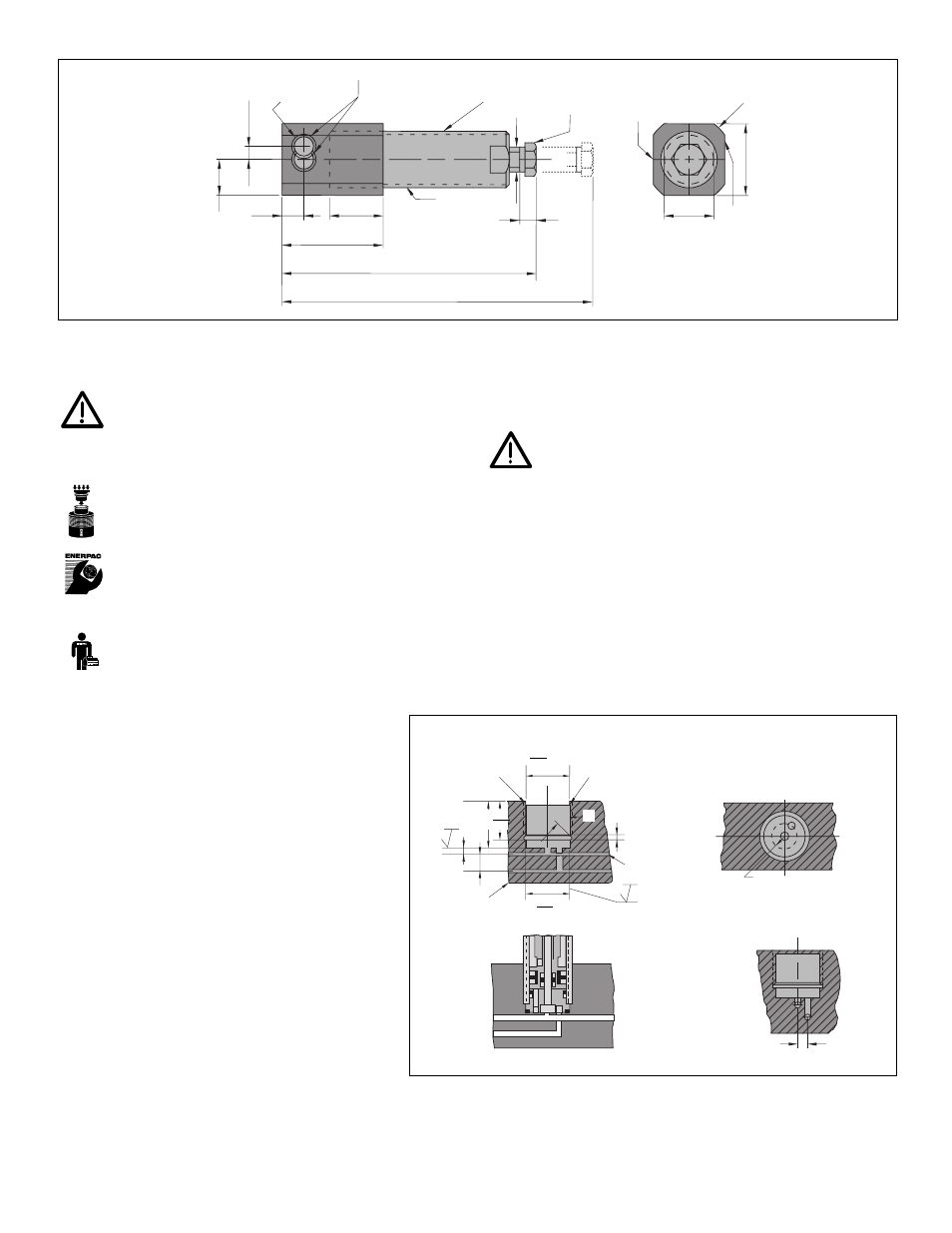

5.97

4.41

1.75

1.00

1.50

.38

.88

1.0 - 12 UNF

.50

1.25

.63

.20

.125-27 NPT

Advance Port

.312-24, .50 DP

.31

Retract Port

CYDA-15

Without Base

MANIFOLD MACHINING INSTRUCTIONS FOR USE

WITHOUT SQUARE BASE

.910

.928

.259

.259 R Ref

Dia.

.775

.790

1.00

1"- 12 UNF-2B

Thread

.12 X 1.02 Dia.

Th’d Relief

.09 Dia. Typ.

32

32

.75 Min.

Hyd. Manifold

45°

.875

.877

Dia.

.19

Cham. 45° X

1.02 Dia.

Figure 1

Figure 2