Det-Tronics UD10 FlexVu Universal Display SAFETY MANUAL User Manual

Page 2

2.1

95-8668

2

DESIGN

The Model UD10 Universal Display is a stand alone

device that performs all the functions of a gas controller

and is classified as Type B smart device according to

IEC61508. It provides an isolated 4-wire 4-20 mA output

that is representative of the received input 4-20 mA

level. The UD10 contains extensive self-diagnostics

and is programmed to send the current output to a

specified failure state upon internal detection of a

failure (see UD10 instruction manual for details). Alarm

and Fault relay contact outputs are provided in addition

to the analog signal output, and can be programmed

in the field by the user. The relay output and analog

output are not to be used in combination for the safety

function.

Safety-Certification of the UD10 Universal Display

includes:

• the 4-20 mA input and output

• the High Alarm, Auxiliary, and Fault relay outputs

Safety Certification of the UD10 Universal Display

includes the following non-interfering outputs:

- UD10 display and magnetic switches

- HART communication

- Modbus communication

- Foundation Fieldbus communication.

The HART communication protocol is non-interfering

and is to be used for diagnostics within the SIL 2

safety loop in the Safety operation mode. Diagnostics

are defined as read only information. Local HART

communication with the UD10 Universal Display using

a handheld HART field communicator, or AMS program

connected to the 4-20 mA output, is acceptable. Proper

analog signal loop resistance must be installed as

documented in the instruction manual to enable local

HART communication.

vALID INpUT RANGE

UD10 fault annunciation is provided on the 4-20 mA

signal output loop by signaling to a specific mA current

output level. The receiving device must be programmed

to indicate a fault condition when current levels reach

undercurrent of 3.6 mA or less.

NOTE

The UD10 analog signal and relay outputs are not

safety-rated during detector warm-up, calibration

mode, or during signal output loop testing.

Alternative means should be used at the job site

to ensure facility safety during these activities.

DIAGNOSTIC RESpONSE TIME

The UD10 Universal Display will perform all critical

diagnostic functions within 58 minutes, worst case

diagnostic detection time.

CERTIFICATION

The UD10 Safety-Certified version is certified by exida

®

to IEC61508 for single input use in low demand, SIL 2

Safety Instrumented Systems.

SAFETY-CERTIFIED pRODUCT IDENTIFICATION

Safety Certification of all UD10 models meeting SIL 2

safety standards is clearly identified on the product label.

INSTALLATION

NOTE

For complete information regarding performance,

installation, operation, maintenance and

specifications of Model UD10, refer to instruction

manual 95-8661.

No special or additional detector installation

requirements exist above and beyond the standard

installation practices documented in the Model UD10

instruction manual.

The operating temperature range for the Safety

Certified UD10 is –55°C to +75°C for the analog output

and –45°C to +75°C for the relay outputs. Other

environmental operating specifications are applicable

as published in the general specifications section in the

Model UD10 instruction manual.

The UD10 operating power distribution system should

be designed and installed so the terminal voltage does

not drop below 18 Vdc when measured at any specific

location. The maximum current limit per device must

be less than 2 amperes. The external system providing

power to the UD10 must have over-voltage protection

that ensures supply voltage does not exceed 30 Vdc.

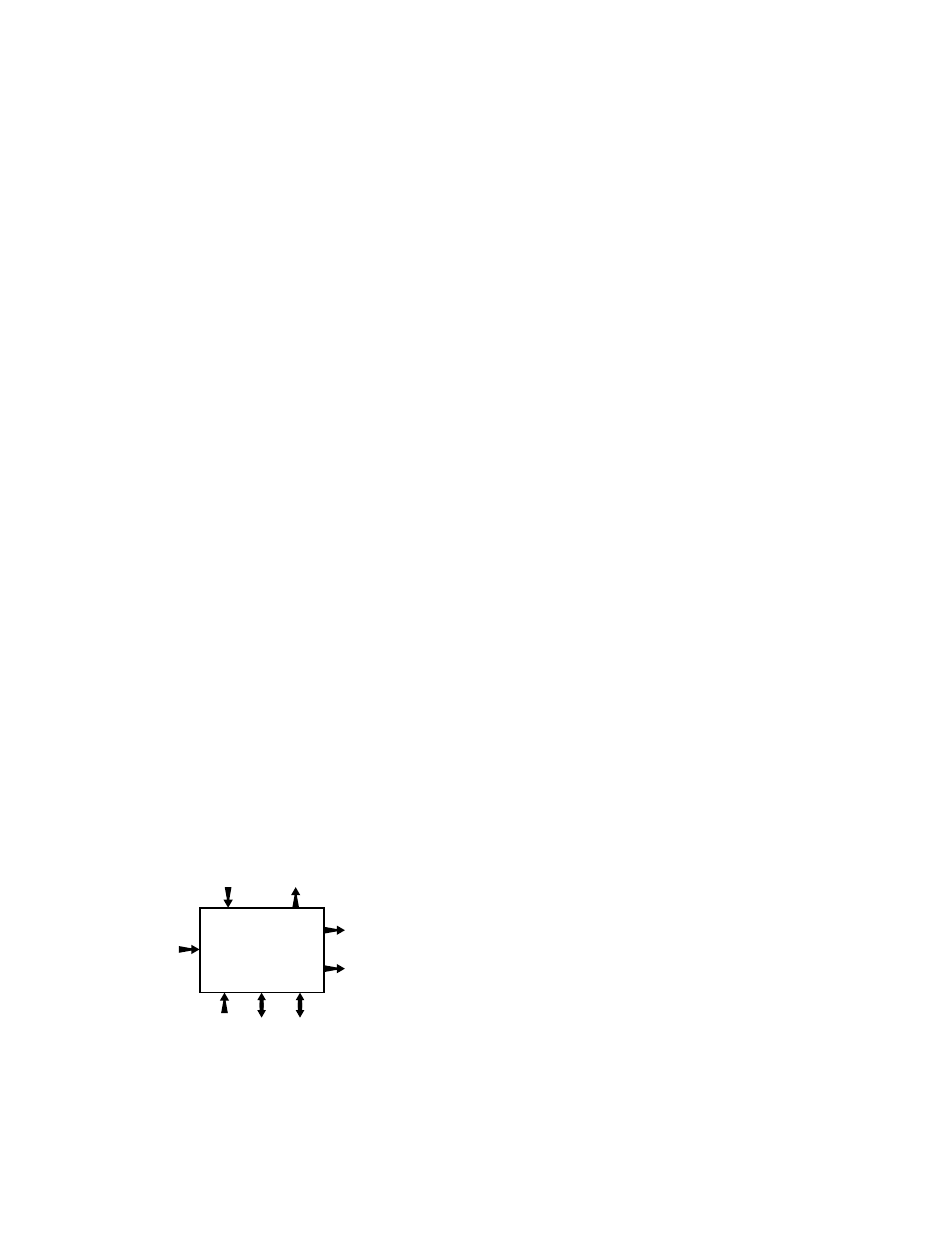

UD10

Universal

Display

4-20 mA Current Loop

with HART

(HART Master)

4-20 mA Current Loop

(HART Slave)

Relay Outputs

(Fault, High Alarm,

Auxiliary)

24 VDC

Visual Outputs

(Output Meter,

Alarm & Menu)

Ma

gnetic S

witc

hes

MODB

US /

Foundation F

ieldb

us

HAR

T

(via 4-20 mA Output)

Power

Visual

Input

Outputs

Configuration & Maintenance