Calibration – Det-Tronics UD20 FlexVu Explosion-Proof Universal Display Unit User Manual

Page 8

3.1

95-8620

6

cAlibrAtion

The calibration process is automatic, with the exception

of gas delivery. LEDs on the GT3000 and messages on

the UD20 faceplate guide the operator when to apply

and remove the calibration gas. See Table 1.

NOTE

The UD20 allows the operator to adjust the

calibration gas concentration within the range of

30 to 90% full scale. The default value for all gas

sensors except oxygen is 50% full scale. Oxygen

sensors use a default value of 20.9%.

gENERAl CAlIbRATION INfORmATION

All GT3000 Gas Detectors require a two-point

calibration — zero and span.

The calibration process can be initiated using the

magnetic switch on the GT3000 or using the magnetic

switches on the UD20 faceplate. All sensors, including

oxygen, should be in clean air (20.9% oxygen) when

the calibration sequence is initiated.

Once calibration is initiated, the process proceeds

automatically. The yellow LED on the GT3000 and

the digital display on the UD20 are used to inform the

operator of the progress of the calibration procedure,

and also signal when to apply and when to remove the

calibration gas.

The calibration can be aborted after zero calibration

by activating the magnetic switch on the GT3000 or

navigating the UD20 menu.

If the calibration sequence is aborted or not completed

successfully, the detector reverts back to the previous

calibration values and signals a calibration fault. If

a successful calibration cannot be performed, the

calibration fault can be cleared by activating the

magnetic switch on the GT3000 for one second.

For help assessing when a fault has occurred see Table

2.

The calibration process can fail for the following causes:

• Zero is out of range

• Span is out of range

• Time-Out.

The time and date of calibration events are logged

in the GT3000’s non-volatile memory along with the

calibration outcome. Possible calibration scenarios

include the following:

• Successful Calibration

• Aborted Calibration

• Failed Calibration

NOTE

The calibration procedure must be completed

within a ten minute period. If the calibration is not

completed, a calibration fault will be generated

and the previous calibration data will be used.

NOTE

To ensure reliable protection, it is important to

check and calibrate the detection system on a

regularly scheduled basis. The frequency of these

checks is determined by the requirements of the

particular installation – typically 30, 60, or 90 day

intervals, depending on the ambient conditions.

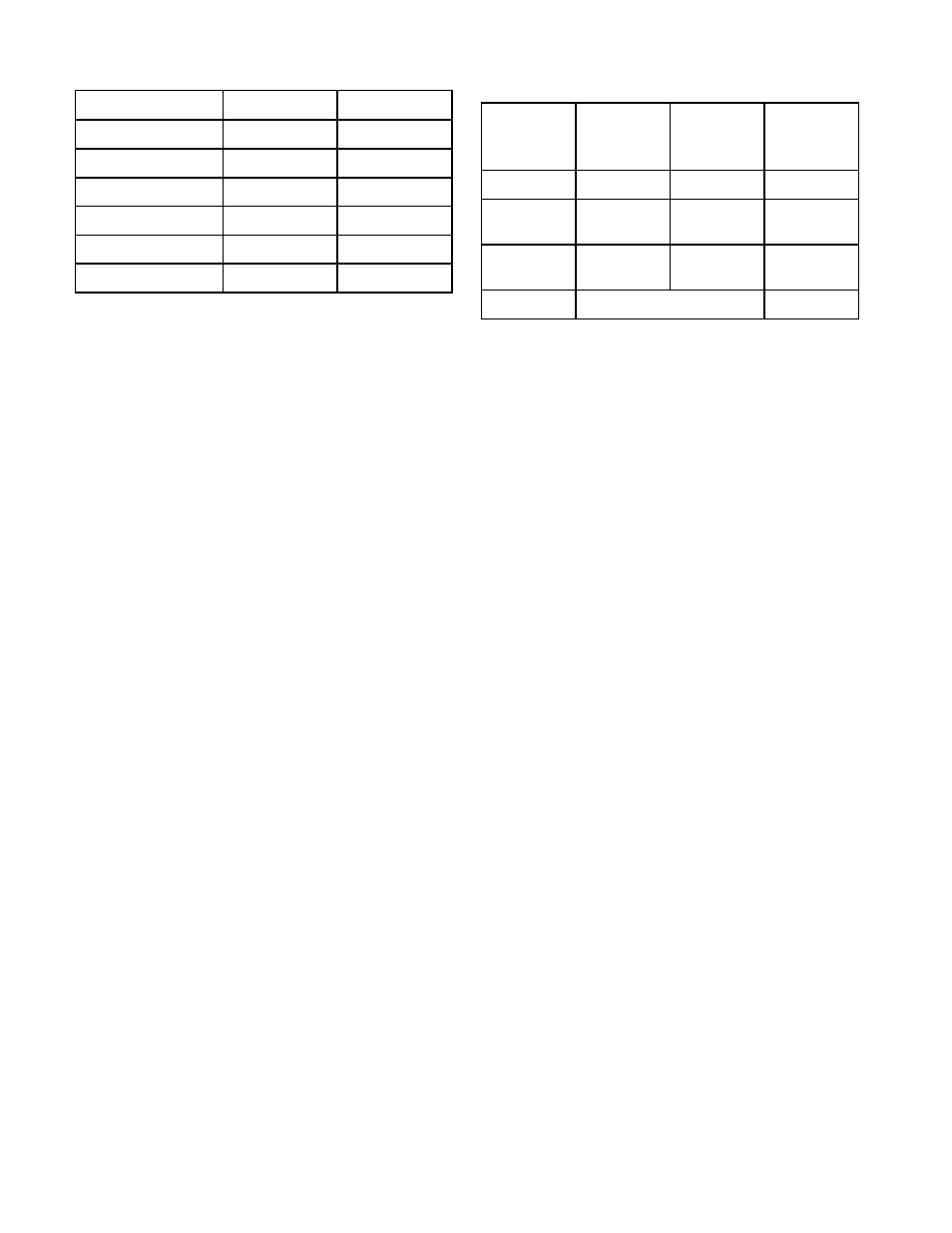

Device Status

green lED

yellow lED

Normal

Steady On

Off

Waiting for Zero

Off

Steady On

Waiting for Gas

Off

Blinking

Waiting for Span

Off

Blinking

Remove Cal Gas

Off

Off

Normal

Steady On

Off

Table 1— GT3000 LEDs During Calibration

Table 2— GT3000 LEDs and 4-20 mA Output

During Various Status Conditions

function

green

lED

yellow

lED

Analog

4-20 mA

Signal

Warm-up

Off

Steady On

3.5

Normal

Operation

Steady On

Off

4-20

Fault

Condition

Off

Steady On

3.5

Calibration

See Table 1

3.8