Theory of operation – Despatch LAD Series WITH PROTOCOL PLUS User Manual

Page 13

5

THEORY OF OPERATION

This section details the function and operation of assemblies and subassemblies on the

Despatch LAD Series Ovens. These ovens have the most effective heat distribution

system and the fastest processing time of any lab ovens their size. They are especially

useful for testing, preheating, sterilizing, drying, aging and curing as well as other

production applications. Horizontal airflow with precision digital control delivers uniform,

fast processing. The overall result is efficient productivity under strenuous conditions.

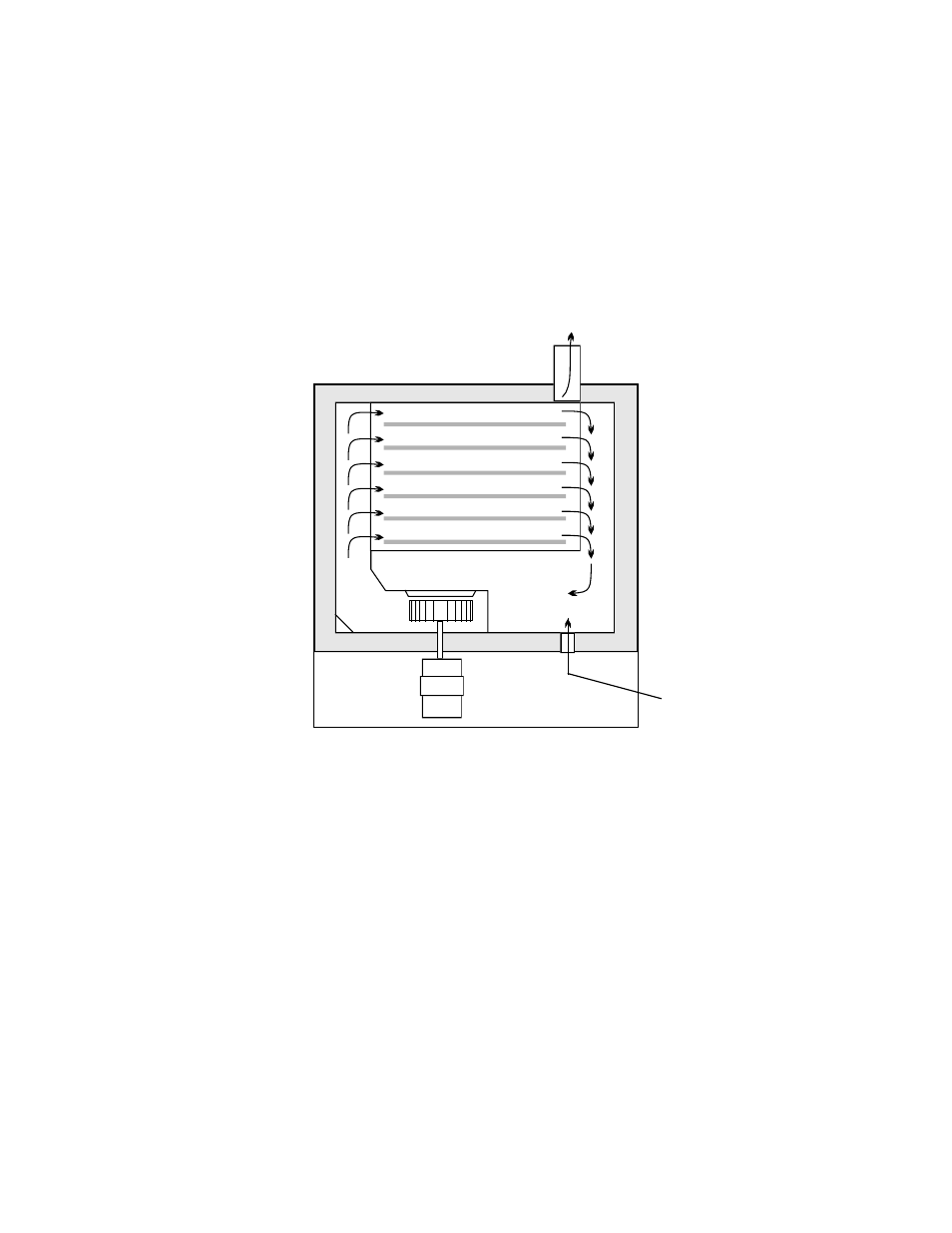

Figure 1. Horizontal Airflow

The unique Despatch computerized design, moves forced convected heat through

perforated stainless steel walls. The air is recirculated with a high volume fan.

Despatch LAD Series Ovens employ higher volume fans than any competitive model.

The chamber can be densely loaded without interfering with the process. The LAD

series air delivery temperature is within 1/2

°

C of the number appearing on the digital

display. Also, fresh air intake is regulated by a panel-mounted damper control. The

exhaust rate is regulated by an adjustable control on the exhaust stack (LAD2-11 and

LAD2-24). The exhaust opening is fixed on the LAD1-42. The exhaust port, located on

the back of the LAD1-42, is covered by a hat bracket. For safety reasons, do not

remove the hat bracket.

Fresh

Air