Safety information, Performance characteristics – Despatch 926E Equipment Manual (C-155)Rev 2/11 User Manual

Page 26

21

To avoid moisture collection in the insulation after sustained operation at low

temperatures, the test chamber should be operated for at least one hour at 205

C (400

F) to evaporate the moisture. Do not exceed this temperature with the cryogenic

models which are insulated with high-temperature-resistant polyurethane (isocyanate)

foamed-in-place resin. This insulation will be damaged if temperatures in excess of 205

C (400

F) are sustained.

Safety Information

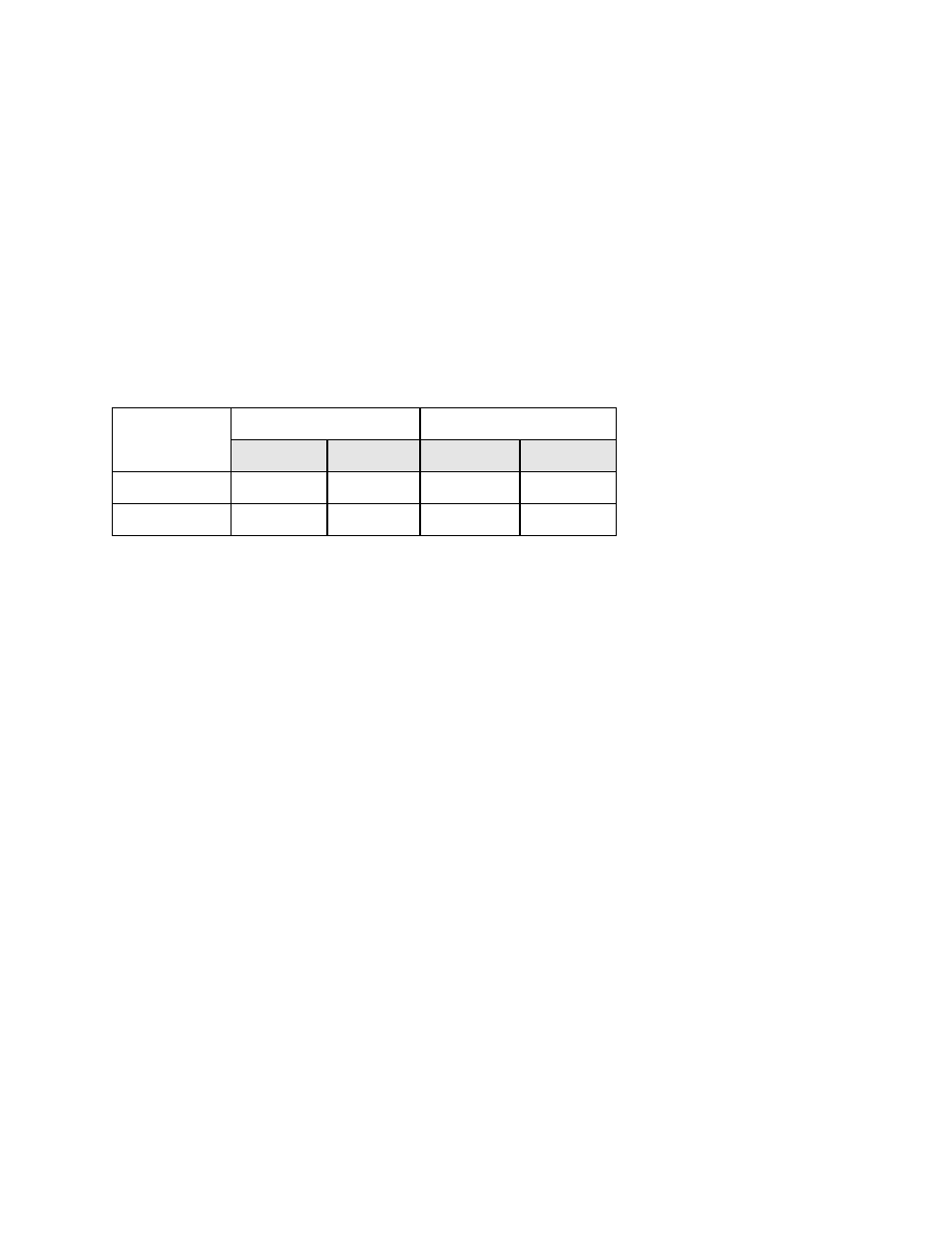

Operating and burst pressures for various hose assemblies are given in the following

table.

Component

Operating Pressure

Burst Pressure

kPa

2

PSI

kPa

2

PSI

CO

2

20685

3000

68950

10000

LN

2

310

45

2586

375

Performance Characteristics

The following tables list the performance characteristics for the test chambers. The

tables are used topically as follows.

1.

Find approximate temperature of test chamber in left-hand column.

2.

Find temperature desired in second column from left.

3.

Determine the CO

2

consumption from the right-hand column under CO

2

CONSUMPTION.

Column AIR lists the amount of CO

2

needed to bring the air temperature in

the test chamber to the desired degree.

The AIR + WALLS column lists the associated amount of CO

2

needed to

bring the air and the chamber walls to the desired temperature.

Column RATE/HOUR lists the hourly rate of CO

2

consumption needed to

maintain the low temperature.

The CO

2

consumption in minutes may vary depending on the heat dissipated

by the size and material of the test object.