Maintenance, Service, Maintenance service – Danuser 2312 AugerBucket User Manual

Page 15

The Auger Bucket is practically maintenance free. There is only one grease zerk used to

lubricate the motor seal. The zerk is located in the motor mounting plate. Grease the motor

seal every 40 hours.

Thoroughly clean the Auger Bucket after each use, and apply a water based, non-corrosive

releasing agent. Do not allow concrete to dry in the bucket or water to freeze in the bucket.

This will cause damage to the rubber flighting and damage the bucket itself.

Rubber flighting disc replacement should be done only when performance has been reduced

or material leaks out of the discharge end when the auger is not rotating. It is not necessary

to replace all of the rubber flights at once. Replace only the flights that have extensive wear

(usually the ones at the discharge end of the auger).

STEP 1: Lower the Auger Bucket onto a flat, level surface.

STEP 2: Shut off the vehicle engine, lower the arms, relieve all hydraulic pressure (by

activating the vehicle controls), and remove the vehicle key before leaving the

vehicle seat.

STEP 3: Disconnect the hydraulic hoses from the vehicle’s auxiliary hydraulics.

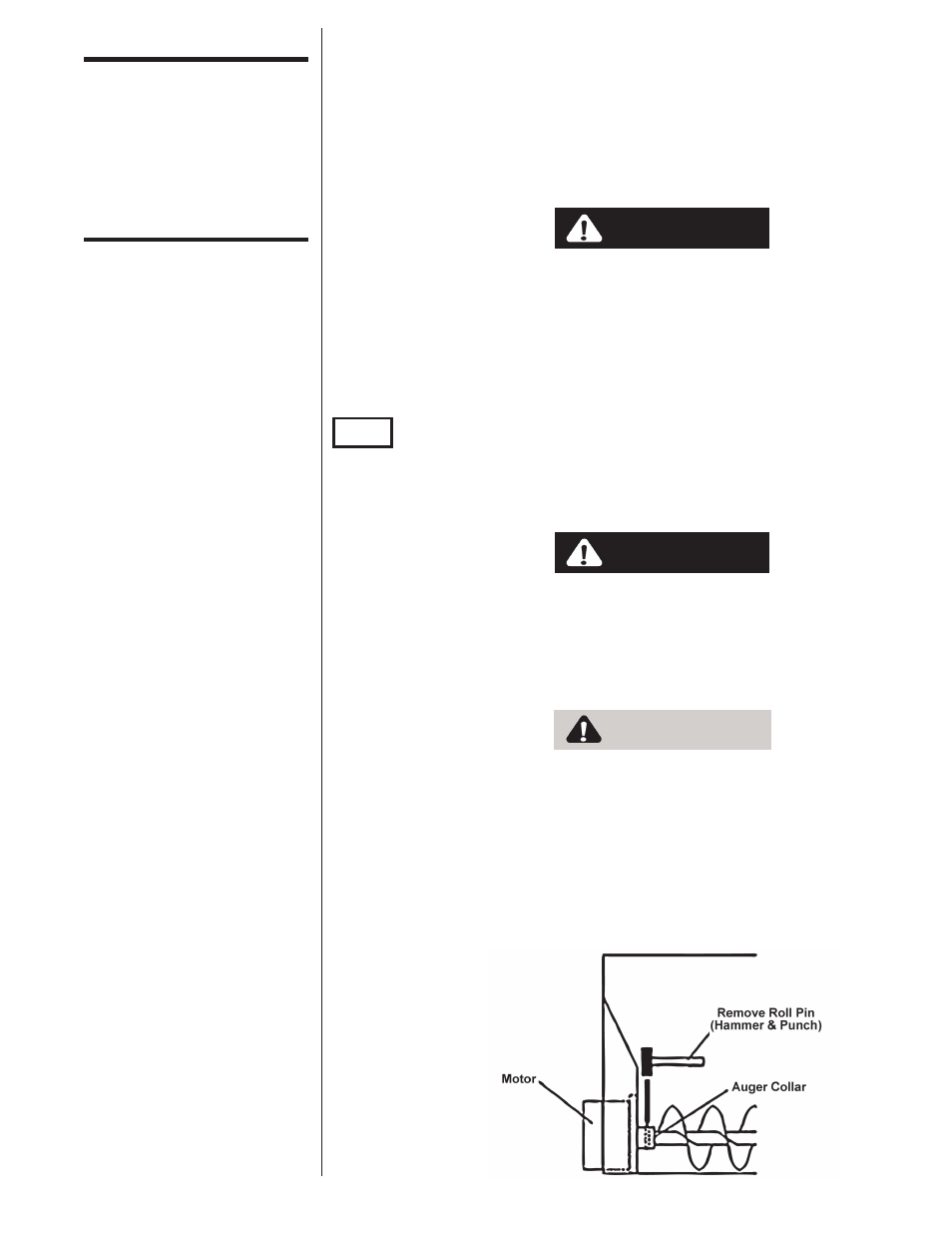

STEP 4: Using a 5/16” punch and hammer, remove the spring pin in the auger collar.

Maintenance

Service

Never attempt repairs or adjustments while the equipment

is in operation.

Never allow anyone under the attachment at any time.

Before disconnecting hydraulic lines or fittings be sure

to relieve all pressure by cycling all hydraulic controls

after shutdown. Remember hydraulic systems are under

pressure whenever the engine is running and may hold

pressure after shutdown.

w A R N i N G

D A N G E R

D A N G E R

15

Use genuine Danuser replacement parts only. Substitute parts may not meet the

standards required for safe, dependable operation.

NOTE