Operation, Fault log display (based on led status), Configurations – Carlin EZ-Temp 90200HM User Manual

Page 2

Model 90200H/HT Microprocessor Temperature Controls — Instructions

Where appliance instructions differ from this manual, follow the appliance instructions.

- 2 -

Carlin part number MN90200HM Rev. 04/16/09

Model 90200H/HT diagnostic LED’s

90200H/HT controls have a green LED (power & fault indicator) and amber LED (firing rate

percent & fault indicator). See LED conditions below.

GREEN

–

OFF

– ON (

Indicates control is oprational)

–

Short on/Long off flash

–

Long on/Short off flash

–

FLASH uniformly

(about once per second, equal on/off durations)

AMBER

–

OFF

– ON

–

Short on/Long off flash

–

Long on/Short off flash

–

ON time equals firing rate percentage

Operation

LED’s Control status

Power Off:

When no power is applied to the Red-White wire, the modulating

output is at LOW FIRE.

Power On:

When power is applied to the Red-White wire, the circuit is energized

starting the Fault Log Display followed by the Self Test. When these are complete

the control becomes operational and turns the Green LED on steady

See Fault log display below — faults will display when power is applied.

NOTE: When flashing, the LED’s flash once every second in Fault display mode. The

green LED flashes once every 3 seconds when in Self Test mode.

Self Test:

When the fault log display is complete, the self test checks the sen-

sor and the microprocessor and internal circuits. This test lasts up to 6 seconds

before the control becomes fully operational. During the self test the green LED

flashes on once every 3 seconds.

Burner @ High-Fire:

When the sensor temp is at or below the operating

temp minus 1/2 the modulating band, the modulation signal is at High-fire. The

Amber LED is full on.

Burner @ Low-Fire:

When the sensor temp is at or above the operating

temp plus 1/2 the modulating band, the modulation signal is at Low-fire. The

Amber LED is full off.

Burner in Proportional Modulation:

When the sensor temperature is in

the modulating band (1/2 the band setting either side of the operating temp),

the control modulation signal varies proportionally between high and low fire. The

Amber LED flashes proportionally. The percentage of time the LED is on equals

the modulating output percentage.

Lockout:

The control goes into lockout on ANY of the fault code conditions

and Logs the fault code indicated below under “Fault log display.”

While in lockout, the Motor modulation output is at low fire. The Amber LED is

off. The green LED flashes uniformly once per second.

Reset from Lockout: The control automatically resets from Lockout when

ALL conditions return to normal. The control returns to whatever state is defined

by its inputs.

Latch-up: Control goes into Latch-up on hardware failure. Control should be re-

placed. The green LED is off. The amber LED is on. (This will occur immediately if

power is turned off and back on again in control is in latch-up.)

Fault log display (based on LED status)

If the control has detected a fault condition, it will display the fault conditions when

power is turned off, then turned on again. Each fault code will occur 4 times. The control

will then display the next fault code, if any. The fault log is erased after displaying the

results. The codes will display in the following sequence:

1

Internal control microprocessor failure.

2

Temperature sensor is shorted.

3

Temperature sensor is open. (Repeats the same code)

4

Internal control microprocessor — pin is open.

5

Modulating band internal circuit is open.

6

Operating temperature internal circuit is open. (Repeats the same code)

7

Control internal diagnostic failure.

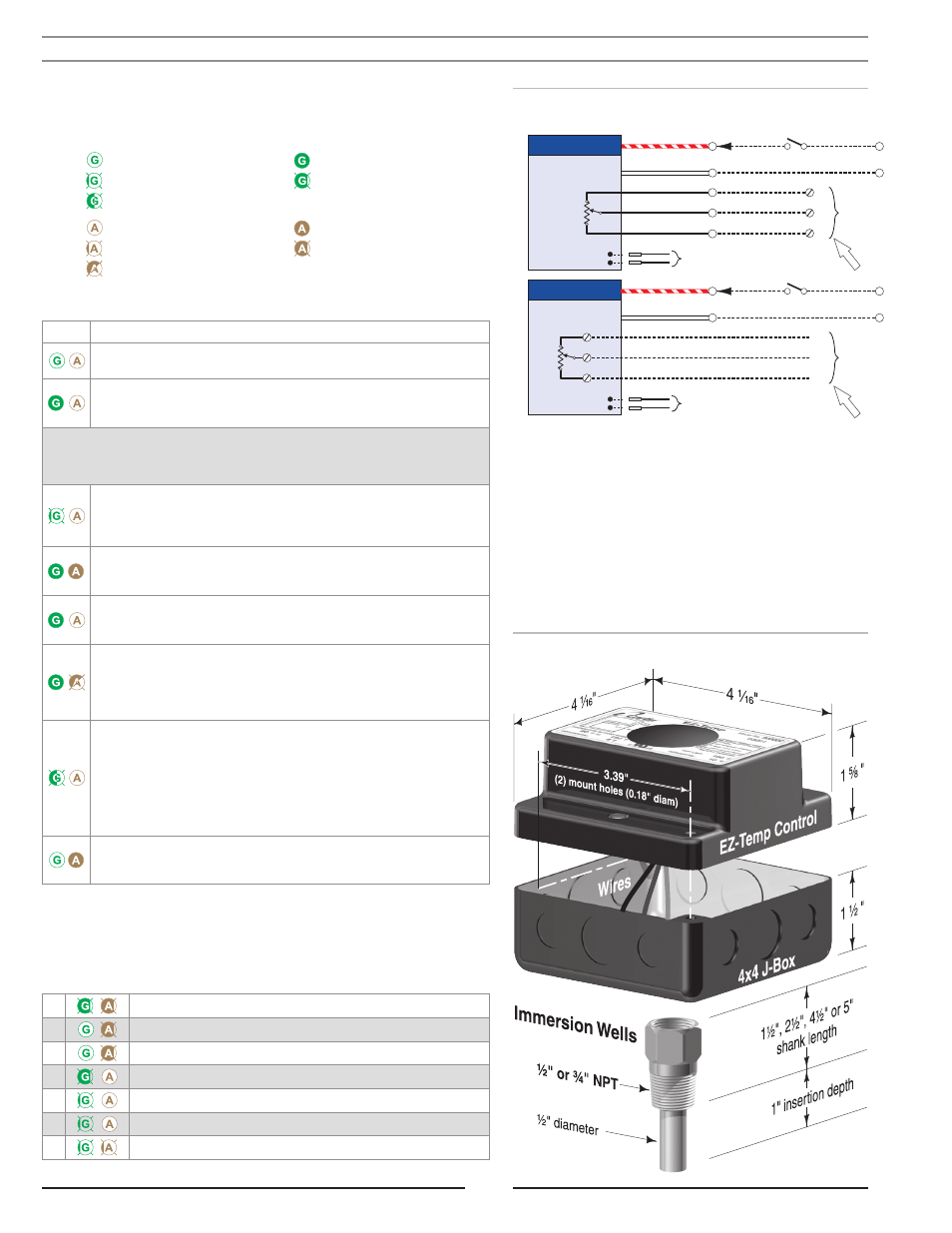

Figure 1 Wiring connections

White

N

H

Service

switch

Red/White

120

VAC

90200H

135-ohm

modulated

device

To sensor

Sensor

W

R

B

Yellow/White

Yellow/Red

Yellow/Black

White

N

H

Service

switch

Red/White

120

VAC

90200HT

135-ohm

modulated

device

To sensor

Sensor

W

R

B

W

R

B

Swap connections to B and W to reverse the motor direction.

Configurations

•

Control kits — 90200H/HT controls mount to a standard 4x4 J-box,

supplied with the control. Mount the box directly to a well (new or

existing) with hardware supplied, or panel mount. See Figure 2 for

dimensions.

•

Well kits — Wells for 90200H sensors are available in the sizes

shown in Figure 2. Well kits include sensor mounting hardware

designed to hold sensor securely in position.

•

Sensors — Sensors are available in single configurations.

Figure 2 Mounting the 90200H/HT