Carbolite Work Tube End Seals User Manual

Page 4

MS76 – 1.00

2

2.0 I

NSTALLATION

2.1 Unpacking & handling

Care must be taken when unpacking the end seals to avoid damaging the silicone seal mating

surfaces. Scratches and marks can lead to lower than intended performance of the end seal.

Ensure all surfaces are clean and free of dirt.

Avoid the use of solvent based cleaners on the end seals.

If needed warm water should be used for cleaning with a lint free cloth.

3.0 O

PERATION

3.1 Fitting of the end seals

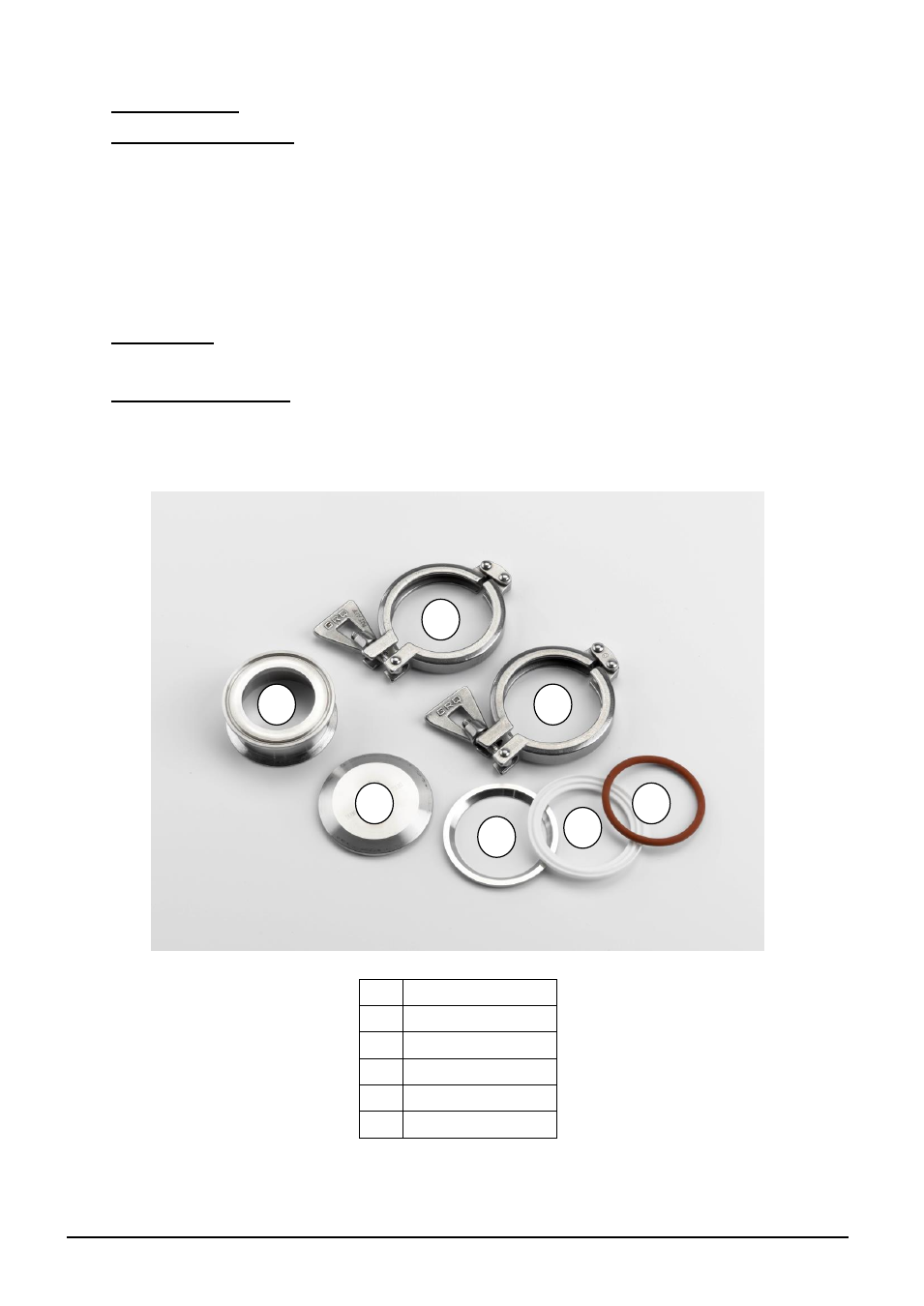

a) Below are the component parts which make up the ‘twin clamp’ end seal.

1

CLAMP RING

2

‘O’ RING

3

CLAMP

4

BOSS

5

SEAL

6

BLANK PLATE

1

1

3

1

6

1

4

1

5

1

2

1

3

1

See also other documents in the category Carbolite Kiln:

- Peak Series (16 pages)

- AX30 (12 pages)

- GP Series (16 pages)

- GPC Series (16 pages)

- LHT Series (16 pages)

- HRF (MF05) (16 pages)

- HRF 7/45 (12 pages)

- ABA 7/35B (72 pages)

- TLD Series (12 pages)

- CR Series (16 pages)

- MTT 12/38/850 (16 pages)

- CF 15 - CF 60 (20 pages)

- PTC 12/20/150 (16 pages)

- CFM Series (16 pages)

- AAF Series (16 pages)

- SNF Series (12 pages)

- HZS Series (16 pages)

- MTF Series (16 pages)

- TZF Series (16 pages)

- GHA Series (24 pages)

- TZF Series (16 pages)

- STF Series (20 pages)

- EHA Series (28 pages)

- CWF Series (16 pages)

- ABF 8/28 (16 pages)

- VCF Series (16 pages)

- ELF Series (16 pages)

- HTR 11/75 (16 pages)

- HST Series (16 pages)

- STF Series (20 pages)

- VST 17/-- (16 pages)

- BLF 17/3 (16 pages)

- RHF Series (17 pages)

- HTF 17 (20 pages)

- RHF Series 3 litre - 35 litre (16 pages)

- CDF 15/1b (16 pages)

- CAF 16/38 (16 pages)

- CAF DIGITAL IMAGING (52 pages)