C.B.S. Scientific DTSK-2401-220 User Manual

Page 40

40

www.cbsscientific.com

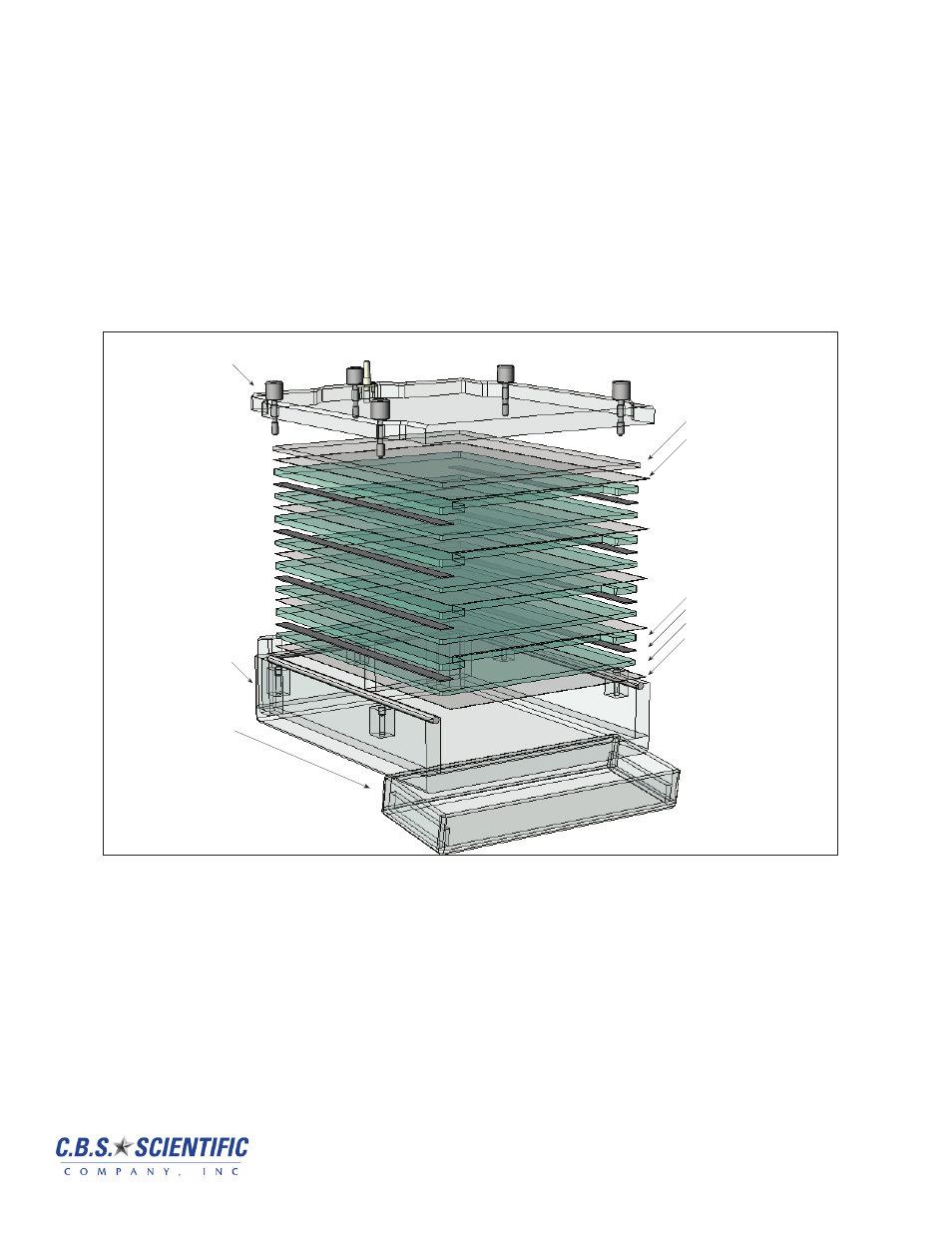

separation sheet

notched glass plate

spacer

unnotched glass plate

shim sheet

front panel with

captive thumbscrews

casting chamber

lid (used to tilt

assembly)

separation sheet

figure 1.

D. Vertical gradient gel casting using GM-40 gradient maker, Mini-Pump and Multi-Gel Caster for DGGE.

1) Multi-Gel Caster Assembly

a) Clean the gel caster with soap and water and the glass plates with alcohol.

b) Place lid on bench and put the top end of the casting chamber (locating groove provided) on

the lid so that it rests at an angle with the gasket facing up.

c) Start by stacking one separation sheet, followed by unnotched glass plate, spacer set, then

notched glass plate. Repeat this sequence until all 4 sets (or 10 sets) are neatly stacked into the

casting chamber. Place one additional separation sheet on the last glass plate. See figure 1.

d) Place front panel on chamber and tighten the 5 captive thumbscrews. With 4 (or 10) sets of

glass plates with 0.75mm spacers, the front panel seals against the gasket and compresses

the glass sandwiches. Using fewer than 4 (or 10) glass plate sets at 0.75mm thick will require

the use of the enclosed shim sheets to achieve a tight seal and light compression of the glass

plate sets. Use of other than 0.75mm thickness spacers may require the use of additional shim

sheets, which must be ordered separately.

e) Bring assembled caster to the vertical position. Test the tightness of the assembly by pulling

one of the polycarbonate shim sheets. If it comes out easily, use extra shims to increase

tightness against the front panel.