Notice – Autoquip SUPER TITAN DOUBLE LONG User Manual

Page 37

37

6.3.2 Bleeding Air From System

1. Bleed air from system by raising lift to 50% of full travel, then lower

completely.

2. Hold “DOWN” button for 60 seconds.

3.

Repeat procedure 5-6 times.

If this does not bleed all air from system,

contact Autoquip.

4. Clean up any spilled oil. Dispose of spilled oil in an environmentally

safe manner.

6.3.3 Hydraulic Velocity Fuse (HVF) Replacement

Prevent serious injury or death.

Never go under lift platform until load is removed and scissors

mechanism is securely blocked in raised position with maintenance

devices and hydraulic pressure is relieved.

The HVF is attached to elbow fitting in rod port of cylinder. Do not use a

swivel fitting between HVF and cylinder. If HVF is installed improperly, it

will not lock up in the event of a hydraulic line failure.

Velocity fuse is not repairable. Replace velocity fuse if

defective.

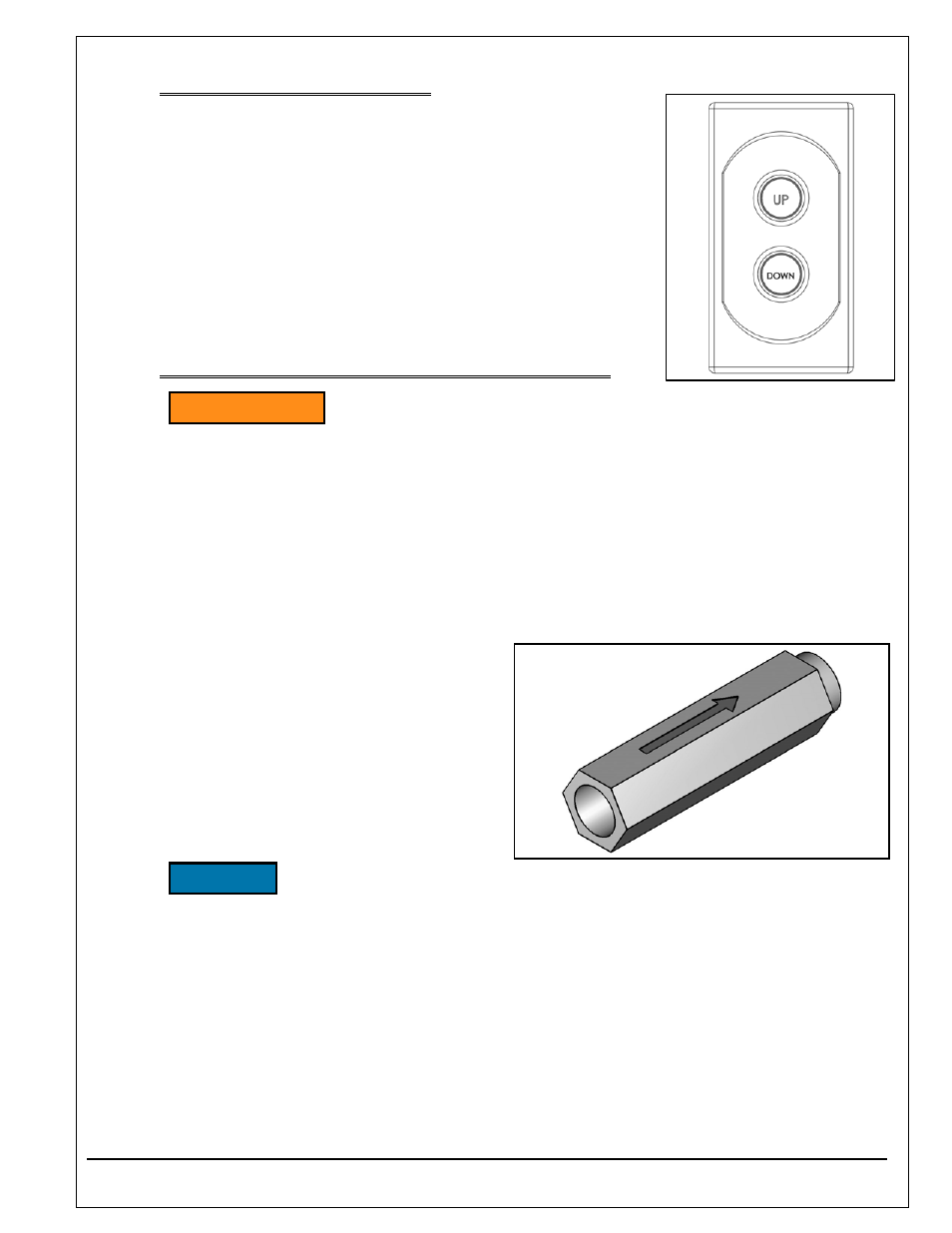

1. Arrow on hydraulic velocity fuse indicates direction

of oil flow restriction. Hydraulic velocity fuse must

be installed with arrow pointing away from cylinder.

Do not use Teflon tape on hydraulic threaded connections. Tape

fragments may damage hydraulic system.

2. Apply Loctite PST #567 pipe thread sealant or equivalent to threads and install fuse to cylinder with

arrow pointing away from cylinder. Tighten fuse.

3. Fill reservoir to full mark if necessary with proper oil.

4. Check all fitting connections for hydraulic leaks and tighten as necessary.

5. Bleed air from system. See “Bleeding Air From System” in this section.

^ WARNING

NOTICE