Autoquip SUPER TITAN DOUBLE LONG User Manual

Page 21

21

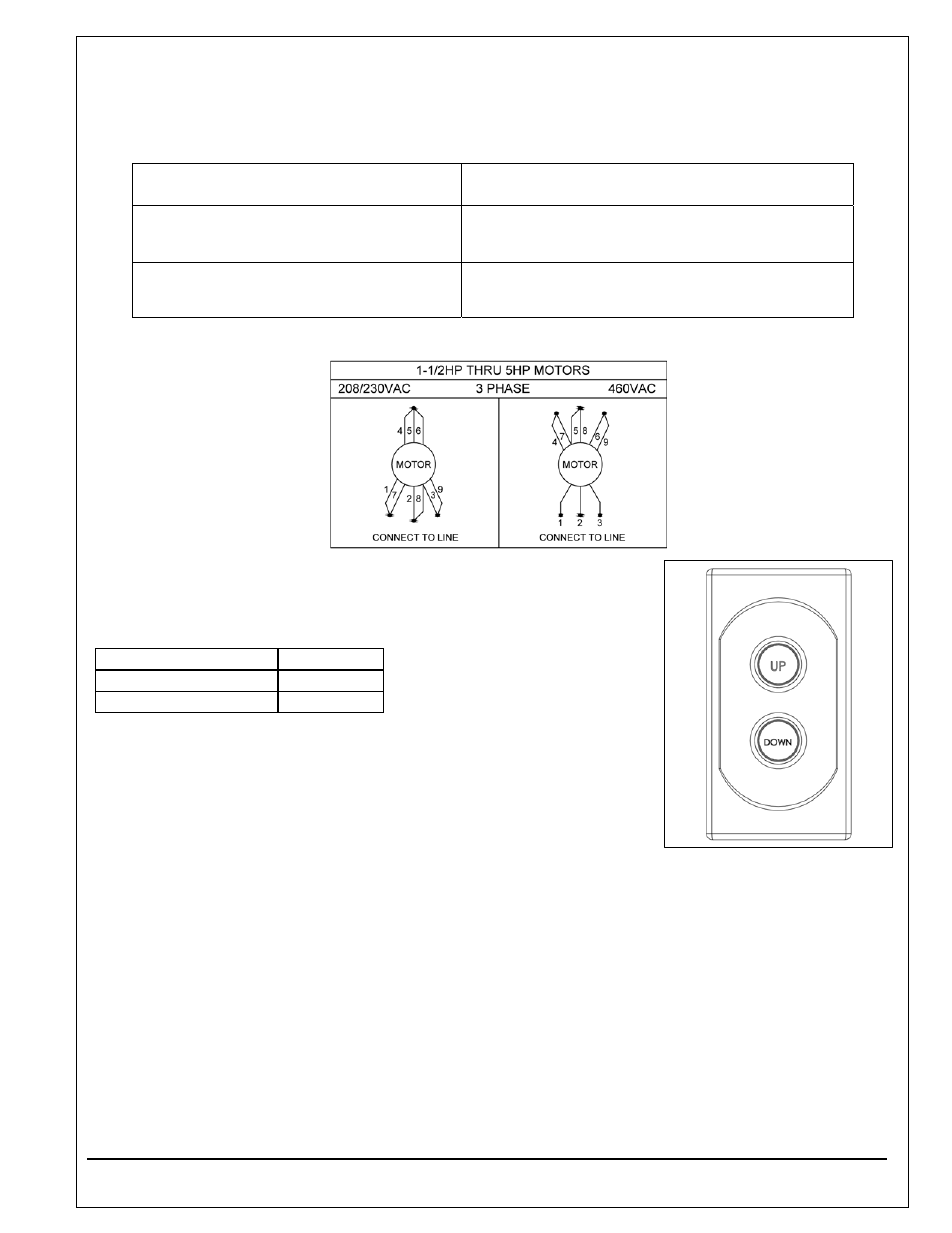

NOTE: For larger horsepower motors, consult factory.

6. Temporarily connect electrical service and hydraulic hoses. The hose

connection on the end of the base frame is 1/2" female NPT.

Hydraulic Piping/Hose Size

Up to 25 feet

½” ID

26 feet to 50 feet

¾” ID

Over 50 feet

1” ID

7. Check the routing of the temporary hydraulic lines to assure that the

hose is clear of legs, bas frame, and platform when lift is in the lowered

position.

8. Fill hydraulic reservoir with proper type and volume of fluid. Oil level

should be 1" to 1-1/2" below the top of the reservoir tank.

9. Press “UP button and raise lift one foot.

10. Press “DOWN” button to fully lower lift. Continue to hold down button for 60 seconds. Repeat

procedure five to seven times to bleed air out of hydraulic system.

11. Raise and lower lift as needed to make positioning adjustments.

12. Adjust platform to a clearance of 1” minimum around perimeter between platform and pit angle.

HP and Voltage

Full Load Amperages

5 HP: 208 / 230 V /60 CY/3 PH

Heavy Duty Motor

208 V=16 Amps

5 HP: 460 V /60 CY/3 PH

Heavy Duty Motor

460 V=7.6 Amps