4 power unit wiring, 5 accordion skirt installation – Autoquip SUPER TITAN DOUBLE LONG User Manual

Page 23

23

2. The remote contractor power unit is equipped with power unit mounting brackets and can be wall or

floor mounted using these brackets. If equipped with a vertical power unit, optional power unit

mounting brackets must be used for wall mounting.

3. The electrical work is to be done in accordance with local codes by a qualified electrician. See the

“Maintenance” section for the standard wiring diagram.

4. If permanent electrical work is not complete, some means of temporary power with an on/off device

for the motor will be required.

5. Fill the reservoir with oil per instructions in the "Maintenance” section.

4.4 Power Unit Wiring

4.4.1 Heavy Duty Remote Power Unit

1. The Vertical 'HD' Power unit utilizes a 5 HP/ 208-230-460 Volt / 60 hertz / 3 phase Heavy Duty motor,

(with a 30 minute continuous duty rating). The power unit is coupled with a high-pressure positive

displacement gear pump, and Autoquip Corporation’s patented Deltatrol valve assembly.

2. The motor connection diagram should be referenced in connecting the motors to a power source.

Remember that heavy wire must be used all the way to the power source.

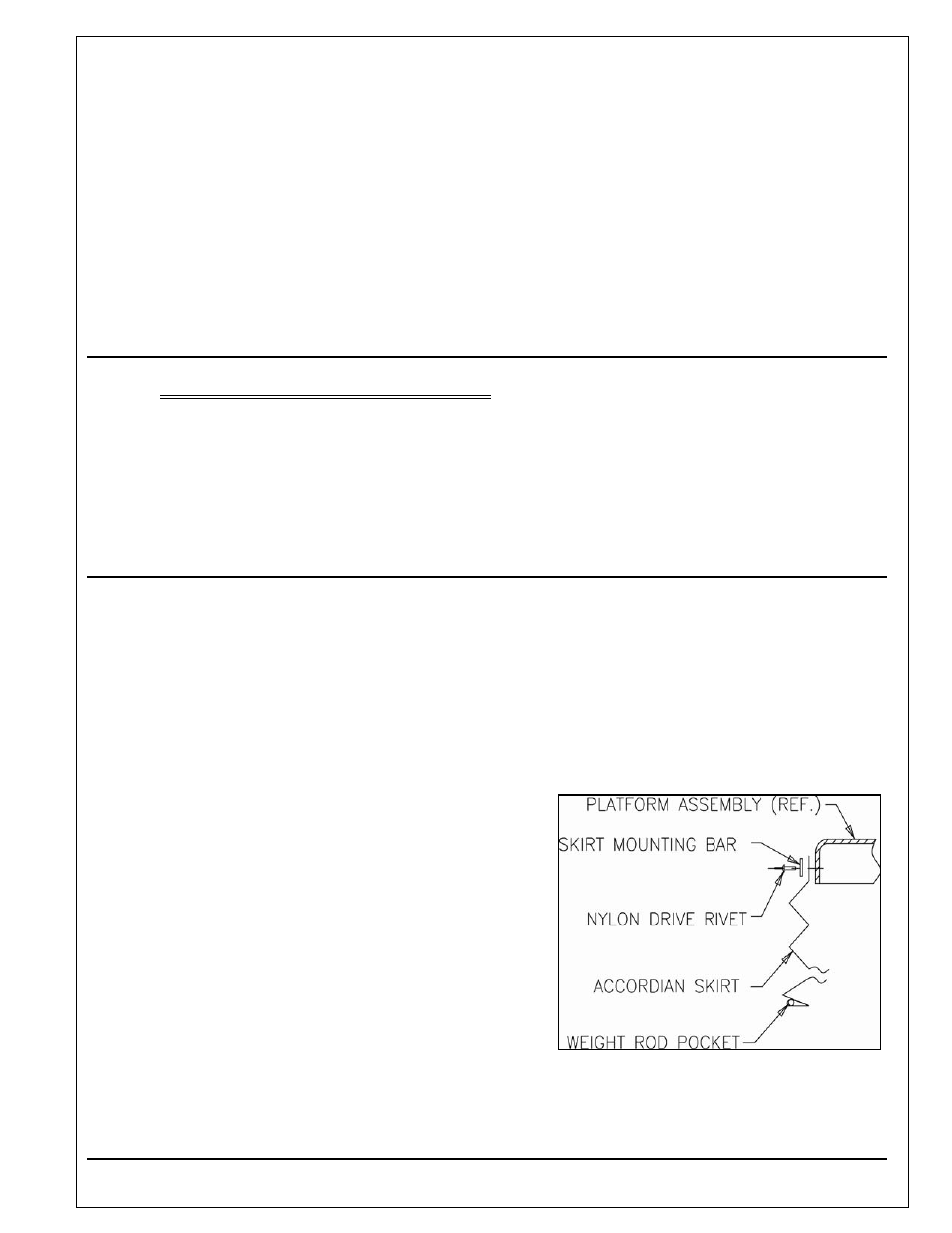

4.5 Accordion Skirt Installation

1. Position platform in raised position. Engage maintenance locks (see “Lift Blocking Instructions”

section). Position accordion with weight rod pocket at bottom and mounting collar at top. The

breathable material when provided must be positioned at top of skirt with mounting collar.

2. Slip skirt over end of platform. Turn skirt as required to slide over other end of platform and leg

assembly. The skirt should be in position under platform while enveloping base assembly.

3. Select from the following mounting configurations.

Mounting Accordion Skirt On Platform Side

Raise one side of skirt along with a skirt-mounting bar (1/8”

x 1”) to (1) side of platform. When possible, center skirt-

mounting collar and skirt-mounting bar (1/8” x 1”) on

platform side.

Align pre-drilled holes in side of platform with skirt-mounting

bar holes and punch holes in skirt-mounting collar.

Push a nylon drive rivet through each hole in skirt-mounting

bar. Hammer aluminum pin into rivet until flush with rivet

head. Repeat mounting process for remaining sides of

accordion skirt.