Autoquip SUPER TITAN DOUBLE LONG User Manual

Page 36

36

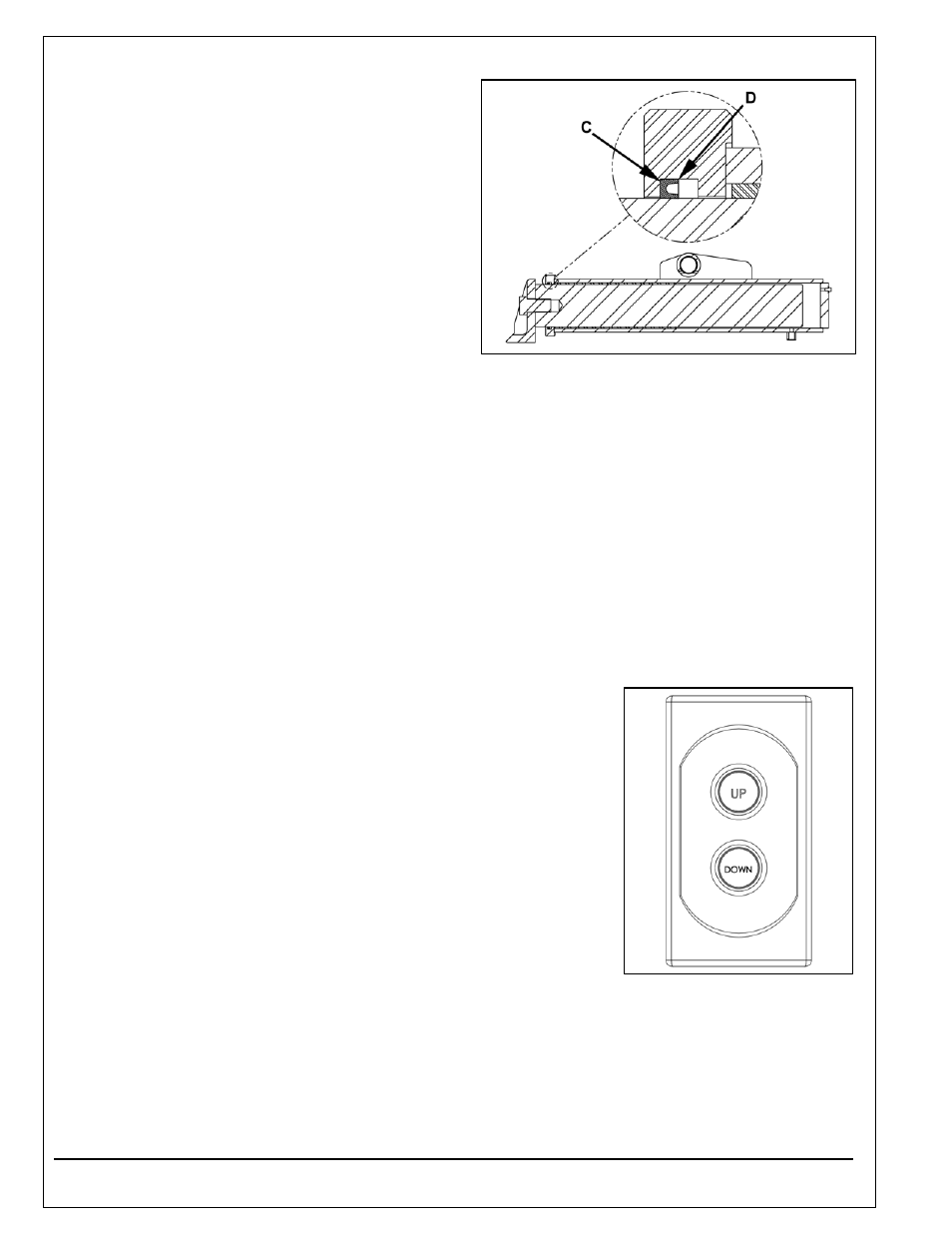

6.3.1.2. Replace Cylinder Seals

1. Remove sealing ring (C).

2. Use a bright light to inspect inner walls of barrel.

Use a cylinder hone to remove any apparent nicks

or scratches. Clean and flush the barrel after

honing.

3. Inspect ram and seal groove (D) for nicks or

scratches that could affect seal or barrel walls;

remove as necessary.

4. Clean seal groove (D) thoroughly and install new

seal and backup ring. Make sure backup ring is

toward open end of cylinder.

6.3.1.3. Cylinder Ram Replacement

1. Clean ram of all foreign materials

2. Liberally lubricate the ram and seal with CLEAN grease or oil.

3. Insert ram carefully back into cylinder taking precaution against pinching or tearing seal ring.

4. Position cylinder foot and reinstall thrust angle clips (A).

5. Reconnect cylinder hose.

6.3.1.4. Placing Cylinder Back Into Service

Loctite PST #567 pipe thread sealant or equivalent is recommended. Do

not use Teflon tape. Tape fragments may cause hydraulic system to

malfunction.

1. Check that lift anchors are tight (when used). Check all pins and other

mechanical and hydraulic connections.

2. Restore oil level. See oil recommendations in “Oil Requirements”

section.

3. Turn on electrical power and press “UP” button. Loosen the bleeder

plug at the top end of the ram casing and operate the pump to remove

trapped air from the ram. When clear oil appears, tighten the plug and

raise the lift slightly to remove the maintenance locks.

4. Lower lift completely and hold “DOWN” button for 60 seconds to allow

air in cylinders to bleed back into reservoir.

5. Raise lift to 25 – 50% of full travel, then lower and hold “DOWN” button for an additional 60 seconds.

Repeat procedure 8 – 10 times.

6. Clean oil fill breather cap.