Warning – Autoquip SUPER TITAN DOUBLE LONG User Manual

Page 20

20

Prevent serious injury or death.

Depending on model, weight of lift ranges from 7,000 – 10,000 lbs.

Use a properly rated lifting device to move and install lift.

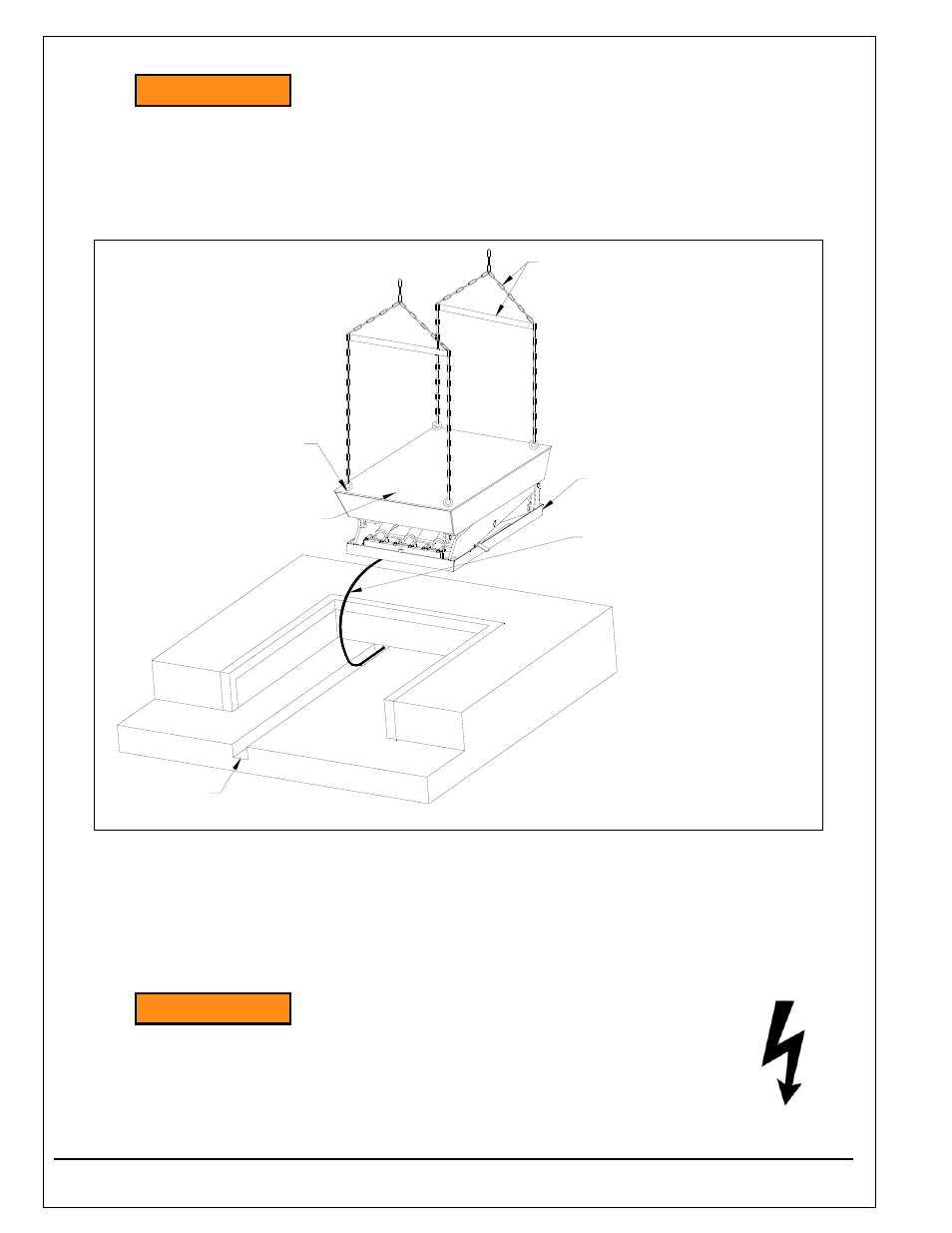

4. Lower lift into pit and check for proper height. Lift must be solid and flush with pit curb angle framing

(D). If needed, shim to desired height. DO NOT “spot” shim. Shim along full length of frame. This will

prevent frame from sagging under load.

5. Remove the shipping bolt and eye bolts from the lift and hydraulically raise the platform. Failing to

remove the shipping bolts before operation will cause permanent damage to the lift.

Prevent serious injury or death.

Electrical service installation must be performed by a licensed

electrician and conform to all local and national electrical codes.

^ WARNING

^ WARNING

TEMPORARY HYDRAULIC HOSE

(DO NOT PINCH OR CRUSH

WHEN INSTALLING LIFT)

BASE FRAME IS PRE-DRILLED

WITH HOLES FOR LAGGING LIFT

SECURELY TO PIT FLOOR

TRENCH

(OPTIONAL)

SHIPPING BOLT

(4) 3/4-10 UNC LIFTING

EYES (BY INSTALLER)

TO FIT IN TAPPED HOLES

IN PLATFORM

1/2" NPT FEMALE FITTING IS

PROVIDED ON CLEVIS END OF

BASE ASSEMBLY FOR

CONNECTION OF HOSE

LIFTING CHAIN WITH

SPREADER BAR

(BY INSTALLER)