2 shimming and anchoring lift to concrete, 3 remote power unit installation, Warning – Autoquip SUPER TITAN DOUBLE LONG User Manual

Page 22

22

NEVER go under a raised lift platform until load is removed and

lift is securely blocked in raised position with maintenance

devices.

See "Maintenance Device" section of this manual.

Lock-out/tag-out power source.

13. Base frame of lift has pre-drilled holes for anchoring floor. Anchor lift to floor. Lifts with oversize

platforms have minimum pull out requirements of 2,000 lbs. for each anchor. See “Shimming And

Anchoring Lift To Concrete”.

14. Make permanent electrical and hydraulic connections and operate lift through a few cycles.

15. Clean up debris and spilled oil from area. Dispose of oil in an environmentally safe manner.

16. Touch-up paint is available from Autoquip for repair of damaged paint surfaces.

17. Train personnel on lift operation, all safety features and procedures.

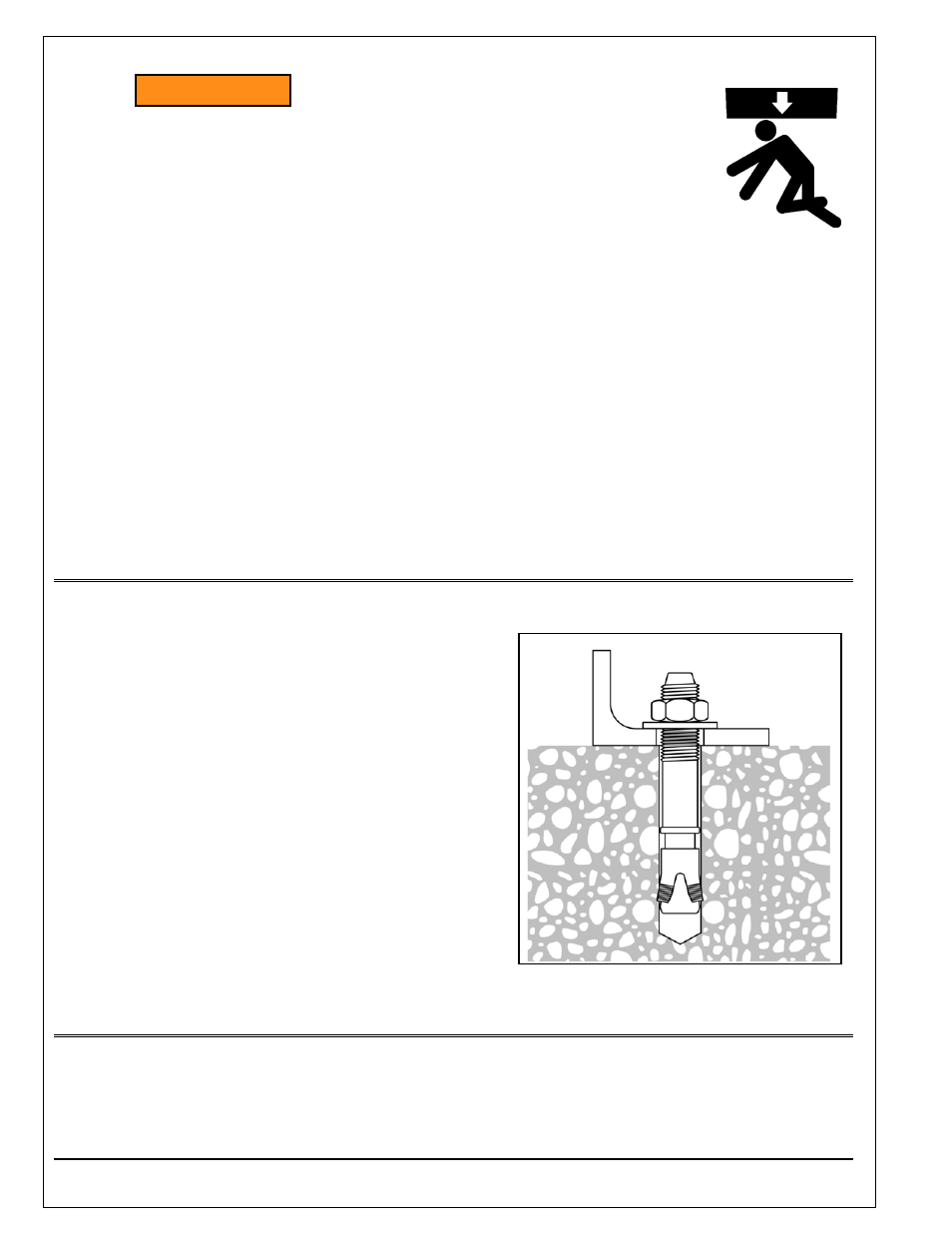

4.2 Shimming And Anchoring Lift To Concrete

Recommended concrete anchor bolts are: HILTI “Kwik-Bolt”, Molly Parabolt or similar.

1. Verify lift is positioned correctly.

2. Drill holes in concrete as specified by anchor bolt

manufacturer.

3. Install and tighten anchors as specified by anchor bolt

manufacturer.

4. After lift has been aligned, leveled and shimmed, and

anchors have been installed, pour grout under entire

base frame.

5. When grout has set and cured, tighten nuts on anchor

bolts.

6. Route hydraulic hose or electrical cord through conduit

in pit wall.

4.3 Remote Power Unit Installation

1. The remote power unit is to be located in an area protected from the elements and should be

installed prior to the lift to facilitate lift operation during installation into the pit.

^ WARNING