Anchor VENUE SERIES - PROFILE SIZE: 160MM X 100MM User Manual

Page 19

19

3.5 Installing Gable End Framing:

Refer to Venue Sizes and Configurations, pages 4 & 5, for layout of Gable End

framing for various tent widths. NOTE: The 9M and 10M only have Center Uprights, the 12M only has Intermediate

Uprights and the 15M and 18M have both Center and Intermediate Uprights. NOTE: A ladder will be necessary to pin

the top of the G.E. uprights to the end arches.

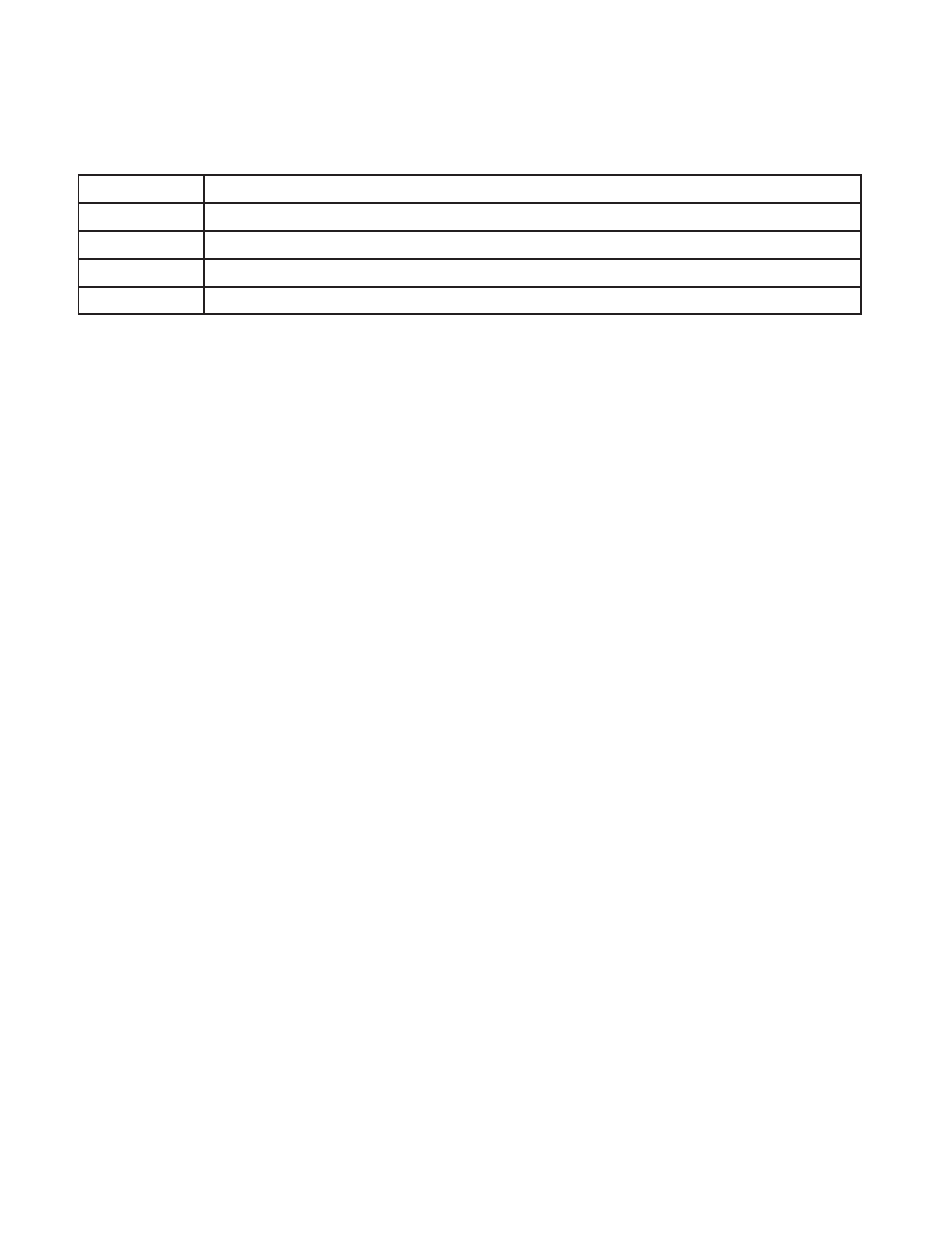

3.5.1 The following is a list of hardware required for each Gable End Upright:

Quantity

Description

1

Locking L-Pin with Stop (16mm x 132mm)

1

Gable End Base Plate L-Pins 5/8” x 200mm (7 7/8”) & R-Clip

1

Anchor Structure Gable Upright Base Plate

2

31 ½” Stakes

3.5.2 At the Center Uprights, connect the insert weldment at the top of the G.E. Upright to the hinge tube at the bottom

of the Ridge Weldment using the Locking L-Pin with Stop. See

Figure 3.5a. IMPORTANT: Pay attention that

the collar on the L-pin is engaged in the safety latch bracket at top of upright.

3.5.3 At the Intermediate Uprights, first connect the G.E. Upright/Rafter Connecting Bracket to the Rafter as shown in

Figure 3.5b. The heads of the bolts that are tightened to clamp the bracket to the rafter must be facing toward

the interior of the tent. Make sure the bolts are tight. Connect the insert weldment at the top of the G.E. Upright

to the hinge tube at the bottom of the G.E. Upright/Rafter Connecting Bracket using the 5/8” Swivel-Lock Pin. See

Figure 3.5b. IMPORTANT: Pay attention that the collar on the L-pin is engaged in safety latch bracket at top

of upright.

3.5.4 After the G.E. Uprights are connected to the arches, swing the G.E. Upright out from either side of vertical and

insert the G.E. Base Plate into the bottom of the G.E. Upright. Swing the upright back to vertical. Adjust the G.E.

Base Plate in or out to suit the adjoining grade and pin using the G.E. Base Plate L-Pin and R-Clip. See

Figure

3.5d. IMPORTANT: Do not stake at this time.

3.5.5 Insert a ¾” Bolt thru the only open holes in the Eave Gusset Plates at both main uprights and secure the Lock-

Nut. Make sure the head of the bolts are on the exterior side of the gusset plate to minimize any snagging pos-

sibilities when installing the gable end fabric. See

Figure 3.5c.

3.5.6 Install the gable end eave purlins by starting with the G.E. Wing Eave Purlins. Place the hooked end over the bolt

installed in step 3.5.5 and drop into place. See

Figure 3.5c. Swing the opposite end with the adjustable eave

hook up until the hook is above the bracket on the G.E. Upright, align and drop into place. See

Figure 3.5d.

Using the purlin fork to pivot the eave purlin into place will allow the installer to work from the ground.

3.5.7 Install the remaining gable end eave purlins between the G.E. uprights by first connecting the curved hook into

the G.E. upright bracket then swing the opposite end with the adjustable eave hook up until the hook is above the

bracket on the G.E. Upright, align and drop into place. See

Figure 3.5d. Using the purlin fork to pivot the eave

purlin into place will allow the installer to work from the ground.

3.5.8 Plumb the G.E. Uprights (both axes) and anchor the base plates. CAUTION: Do not damage the uprights or

installation hardware when driving the stakes.