Step 2: assembling arches – Anchor VENUE SERIES - PROFILE SIZE: 160MM X 100MM User Manual

Page 11

Step 2: Assembling Arches

2.1 Pre-assembly of arch components:

Identify and layout all components according to

Figure 2.1 for the entire

structure. NOTE: Setting uprights and rafters on 4 x 4 wood blocking (or whatever blocking may be available) will make

the insertion of the pins and bolts easier.

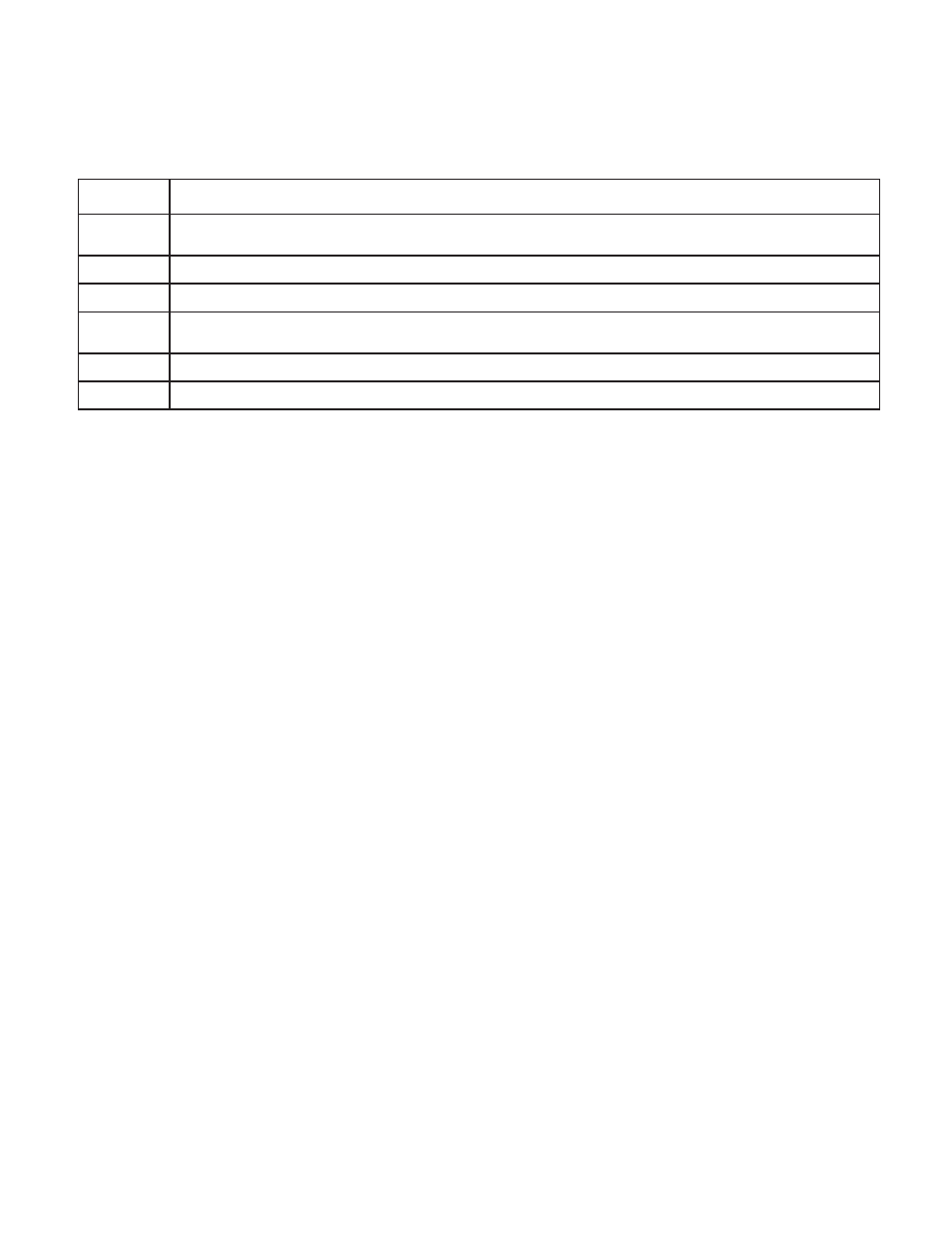

2.1.1 The following is a list of components required for each arch:

Quantity Description

2

Base Plate L-Pins 16mm x 230mm (9”) & R-Clips NOTE: 5/8” x 200mm (7 7/8”) L-Pins are used at

the Gable End base plates

2

Upright Assembly

4

¾”-10 x 6” Bolts and Lock Nuts

4 (8)

¾” x 4” Swivel-Lock Pins (quantity in parenthesis is required if Rafter Extensions are used) NOTE:

5/8” x 4 ½” Swivel-Lock Pins are used at the Gable Ends.

1

Ridge Weldment

2

Rafter Extensions (if applicable)

2.1.2 Identify and layout (1) L-Pin with R-Clip next to each Base Plate. See

Figure 2.2a.

2.1.3 Identify and layout (2) ¾” Lock Nut and Bolt next to each Upright/Rafter connection. See

Figure 2.2b.

2.1.4 Identify and layout (4) ¾” Swivel-Lock Pins next to the Ridge Weldment. See

Figure 2.2c.

2.1.5 If applicable, identify and layout (2) ¾” Swivel-Lock Pins next to each Rafter Extension.

2.1.6 If laying out components for a cable braced bay, refer to Section 2.3 for substitute components required.

2.2 Assembly of Uprights and Rafters (and Rafter Extensions if applicable):

The assembly of the arch-

es is easier if working from one side to the opposite side.

2.2.1 Starting at Base Plate “1”, connect the bottom of the Upright Assembly to the Base Plate using the L-Pin as

shown in

Figure 2.2a. The R-Clip will be inserted later when the Wall Ground Bars are installed. IMPOR-

TANT: The short leg of the L-Pin must be turned down and behind the Safety Bracket on the Base Plate to

keep the L-Pin from sliding out.

2.2.2 Connect Rafter to the Upright Assembly by sliding the Rafter between the two gusset plates and bolting together

using the ¾” Lock Nuts and Bolts as shown in

Figure 2.2b. The connection is easier when inserting one bolt

then rotating the rafter until the second bolt hole is aligned. Tighten to 75 ft-lbs.

IMPORTANT: At the gable

ends, the heads of all bolts must be on the exterior side of the gusset plate to minimize any snagging possibili-

ties when installing the gable end fabric.

2.2.3 Connect Rafters (or Rafter Extensions) to Ridge Weldment using Swivel-Lock Pins as shown in

Figure 2.2c.

Pay attention that the swivel-lock is turned ninety degrees after inserting.

IMPORTANT: At the gable ends,

the head of the pin must be on the exterior side of the rafter to minimize any snagging possibilities when install-

ing the gable end fabric.

2.2.4 If installing Rafter Extensions, connect the Rafter Extension to the Rafter using Swivel-Lock Pins as done to con-

nect the Rafter to the Ridge Weldment. Pay attention that the swivel is turned ninety degrees after inserting.

IMPORTANT: At the gable ends, the head of the pin must be on the exterior side of the rafter to minimize any

snagging possibilities when installing the gable end fabric.

2.2.5 Complete the Arch assembly by connecting the opposite Rafter to the Ridge Weldment, Rafter Extension to Raf-

ter (if applicable), Rafter to Upright and Upright to Base Plate according to steps 2.2.1 thru 2.2.4.

2.2.6 Assemble the remaining arches according to steps 2.2.1 thru 2.2.5.

11