AMMCO 4850 Brake Drum Grinder User Manual

Page 3

AMMCO Brake Drum Grinder • 3

GRINDING THE DRUM

Brake drums may be finished in either of two ways:

Two Step Process - Each brake drum is mounted on

the brake lathe arbor, rough turned and then finish

ground before moving on to the next drum. Only the

boring bar and the grinder are interchanged to main-

tain the absolute accuracy that is necessary for the

professional brake job. DO NOT turn all the drums

then remount and grind each one.

One Step Process - Brake drums with little wear or

those with no out-of-round distortions may simply be

finish ground without prior machining. DO NOT

exceed the recommended depth-of-grind .002" to

.005" (.051 to .127 mm) on any one pass.

The position of the clamp must not be changed

until the set of drums for which the grinding wheel

was dressed have been ground.

Remove the dresser from the drum wall. Check to be

sure that the lathe motor switch is OFF. Adjust the

lathe spindle manually to bring the drum back over the

grinding wheel as far as possible. It may be necessary

to turn the wheel guard on the grinder spindle to gain

clearance. Loosen the wheel guard cap screw to do

this, but DO NOT remove the wheel guard. Also it is

wise to turn the drum by hand for at least one revolu-

tion to make sure that everything is clear.

CAUTION: Always wear safety glasses while

operating grinder.

1. Set the lathe spindle speed to its slowest R.P.M.

2. Start the grinder and the lathe.

3. Use the cross feed handwheel to move the grind-

ing wheel into contact with the drum wall.

4. Set the depth-of-grind from .002" to .005" (.051 to

.0127 mm).

5. Set the infimatic spindle feed from .008" to .010"

(.203 to .254 mm). Engage the feed mechanism.

6. Set the feed stop so that the spindle will automat-

ically stop feeding when the grinding wheel clears the

drum.

Turn, then grind each of the remaining drums of the

set in the same manner. Remember—it is not neces-

sary to dress the grinding wheel for each drum—only

when the grinding angle is changed, when the wheel

becomes “loaded” or dull, or when a new wheel is

installed.

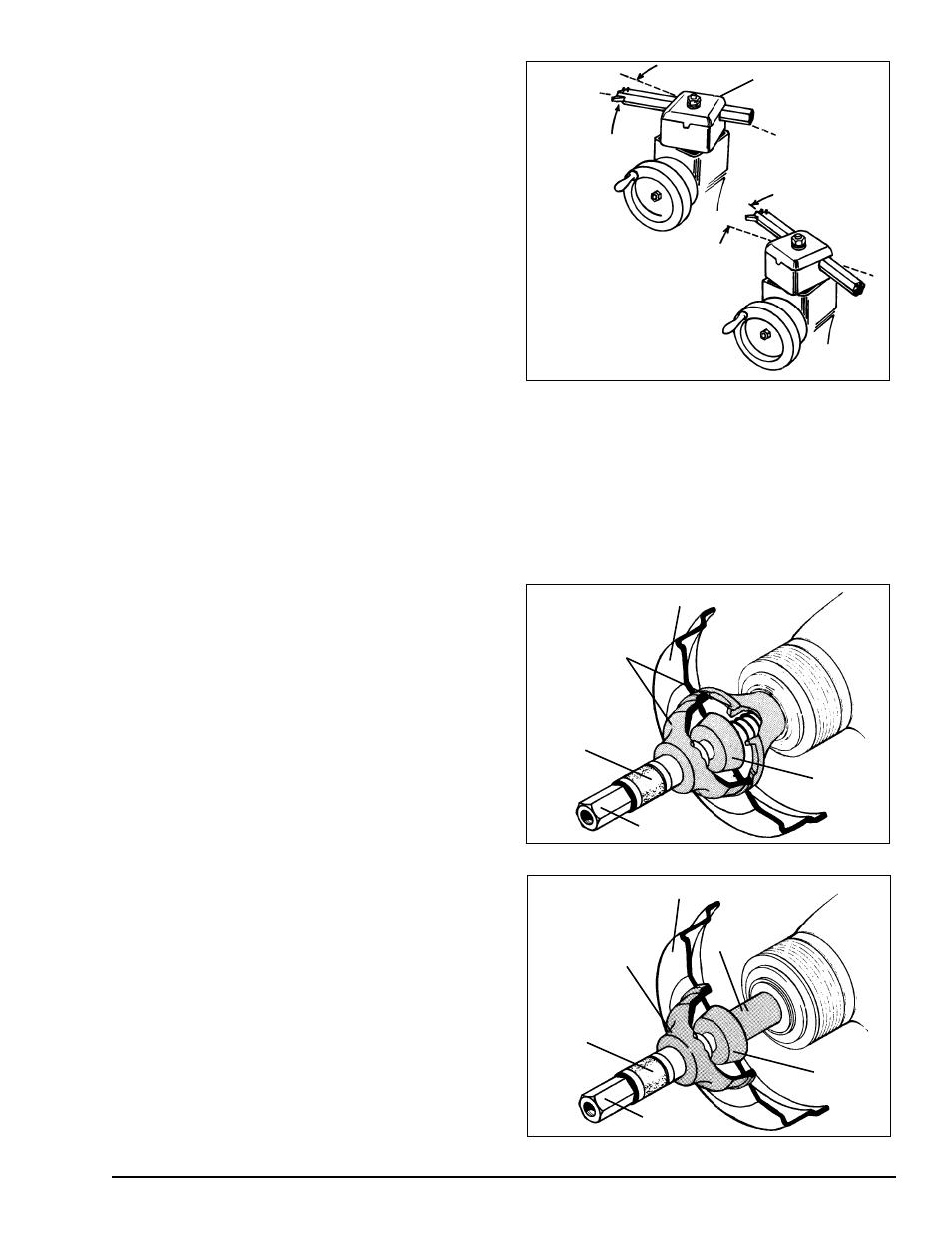

NOTE: Figure 5 illustrates the positioning of the

boring bar clamp for large and small drums. Once

setup for one or the other, the tool post pivot set

screw is locked.The boring bar clamp is not moved

when the boring bar is exchanged with the

grinder.

Figure 5

Hubless drum 10" (254 mm) and smaller may also be

turned and finish ground on AMMCO lathes. These

smaller drums must be mounted differently than full

size types. The larger diameter hubless adapter

(shown in Fig. 6a) on the inside of the drum is NOT

used. Instead, an appropriately sized centering cone

and a spacer are used on the inside with the hubless

adapter on the outside. This clears a working area for

both cutting and grinding, Fig. 6b.

Figure 6a - Mounting For Hubless Drums Over 10" (254mm)

Figure 6b - Mounting For Hubless Drums 10" (254mm) And

Under

Boring Bar Clamp

Swiveled For

Large Diameter

Brake Drums

Swiveled For

Small Diameter

Brake Drums

Centering

Cone

Arbor Nut

Spacer

Cross Section Of Hubless Brake Drum

Self-Aligning

Spacer

Hubless Adapter

Cones

Centering

Cone

Arbor Nut

Cross Section Of Hubless Brake Drum

Self-Aligning

Spacer

Hubless

Adapter

Cone