Led clear flex2 - rgb series – American Lighting CFX4V2-60-RGB User Manual

Page 2

LED Clear Flex2 - RGB Series

Installation intructions for CFX4V2-30-RGB and CFX4V2-60-RGB

INSTALLATION INSTRUCTIONS

1. Disconnect power at source before installation or maintenance.

2. Clear Flex2 requires DC 24V LED Power Supply! Do not connect to 120V AC power!

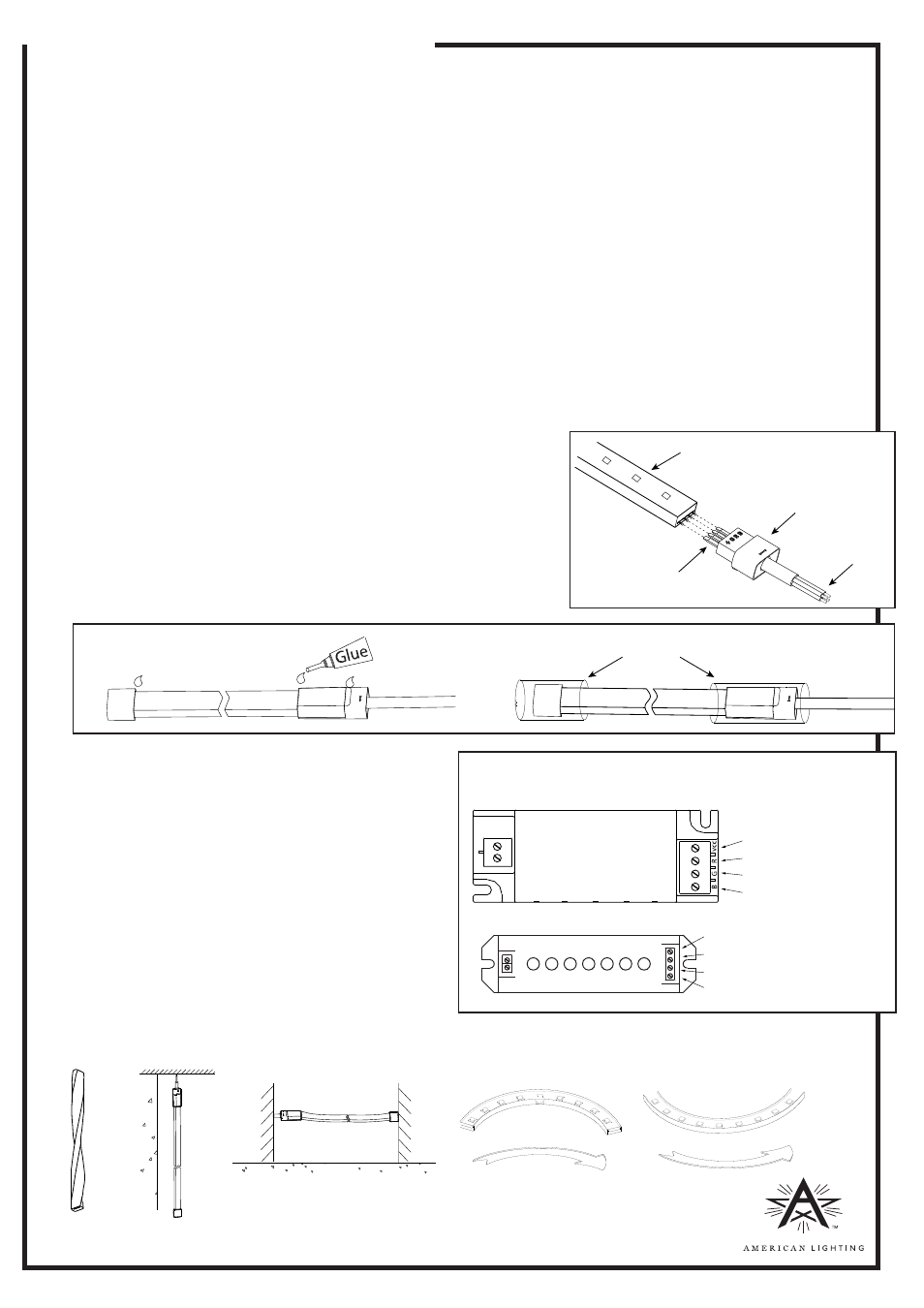

3. To connect power connection kit to the Clear Flex2:

• Push the pins of the connector kit into the end of the Clear Flex2 making sure that the four prongs make full

contact with the internal conductors. See Figure 1.

Note: Polarity is marked “ + R G B ” on the connector kit and Clear Flex2. If polarity is reversed, the LEDs will not be

damaged. They simply will not operate.

• Apply glue into the heat shrink tube, and slide the shrink tube over the joint where the power cord and Clear

Flex2 meet. See Figure 2.

• Use a heat gun to gently apply heat until the shrink tube shrinks in place over the assembly.

4. To connect the end cap to the Clear Flex2:

• Apply glue into the end cap and push the Clear Flex2 into the cap, until it is fully seated.

• Apply glue into the heat shrink tube and slide the shrink tube over the joint where the end cap and the Clear

Flex2 meet.

• Use a heat gun to gently apply heat until the shrink tube shrinks in place over the assembly.

5. To connect two sections of Clear Flex2 together using a splice connector:

• Slide the heat shrink tube onto one of the pieces of Clear Flex2 to be joined.

• Insert the connector pins into this piece of Clear Flex2 being sure to

make full contact with each of the internal conductors.

• Align the second piece of Clear Flex2 and push onto the connector

pins, making full contact with each internal conductor.

• Apply glue around the surface of both ends of the Clear Flex2

pieces and slide the heat shrink tube over the joint.

• Use a heat gun to gently apply heat until the shrink tube shrinks in

place over the assembly. Note: The glue must make contact with all

surfaces of the joints. Be sure that the heat shrink tube completely

covers each of the joints to maintain IP65 rating.

6. Clear Flex2 can be mounted using the mounting

clips (included with kit) or using aluminum

mounting channel (sold separately).

7. Clear Flex2 can be cut every six LEDs (approximately

every 3.9“ for CFX4V2-60-RGB or 7.8” for CFX4V2-30-

RGB). Cut squarely on the cutting mark. Cutting

anywhere else will result in loss of a whole section

(one series/parallel section = 6 LEDs).

8. Connect Clear Flex2 connector kit to controller,

ensuring the polarity is correct. See Figure 3.

9. Connect controller to 24V DC power supply matching

polarity (+ is positive, - is negative). Do not apply

120V AC power to Clear Flex2!

Please also refer to the power supply’s and IR or RF

wireless remote instructions.

DO NOT TWIST, HANG VERTICALLY, SUSPEND UNSUPPORTED IN THE MIDDLE OR BEND ALONG SHORT SIDE:

RV1317 www.americanlighting.com

Figure 1

Heat shrink tube

Figure 2

Figure 3

Ч

Ч

Ч

Ч

Ч

Connector pins

Lighted surface

Connector kit

Colored wires

(inside jacket)

Connect Yellow wire to VCC

Red wire to “R” terminal

Green wire to “G” terminal

Blue wire to “B” terminal

Connect colored wires from connector kit (shown

in Figure 1) to terminal matching polarity.

LED CONTROLLER

CFX4-144W-24V

connections

CFX4V2-360W-24V

connections

Connect Yellow wire to V

Blue wire to “B” terminal

Red wire to “R” terminal

Green wire to “G” terminal