Echo 74624S Owners Manual v.2 User Manual

Page 19

17

OPERATION

4.6 hYdraulic feed conTrol

the bear Cat chipper is equipped with a pre-programmed

hydraulic feed control located under the control panel. the

controller monitors chipper rotor RPM, controls the feed

roller, and provides routine maintenance alerts.

the controller can be turned off with the switch located below

the control panel. If the controller becomes damaged, the

chipper will still run with the controller shut off, however all

of the controller functions will be disabled. the feed roller

will have to be controlled with the control arm.

The feed conTrol funcTionS are furTher

deTailed beloW:

the controller monitors the RPM of the chipper rotor. If

the RPM drops below the preset range, the feed roller

is stopped. When the RPM are back up to an accept-

able level, the feed roller is reengaged.

the controller also has a “try again” feature. the

controller monitors the hydraulic pressure of the feed

roller. If it senses the level is too high (the feed roller

becomes obstructed) the controller will reverse the feed

roller , removing the material trying to be chipped. the

controller will then engage the roller into the forward

position and try to feed the material again. If this cycle

continues, the obstruction will have to be removed

manually, trimmed, and/or repositioned.

to disable the try again feature, disconnect the 2-pin

connector going to the pressure switch. It is located

above the feed roller motor on the Sa-1987 assembly.

the controller will also flash service alerts when it is

started. every 15 hours it will flash 5 times to indicate

the chipper blades should be sharpened. every 100

hours it will flash 10 times to indicate the engine oil

should be changed.

noTe: The RPM sensor on the rotor must be flashing or

the controller won’t work. Clearance between the sensor

and the bolt must be between 1/32” and 3/32”.

1.

2.

3.

4.

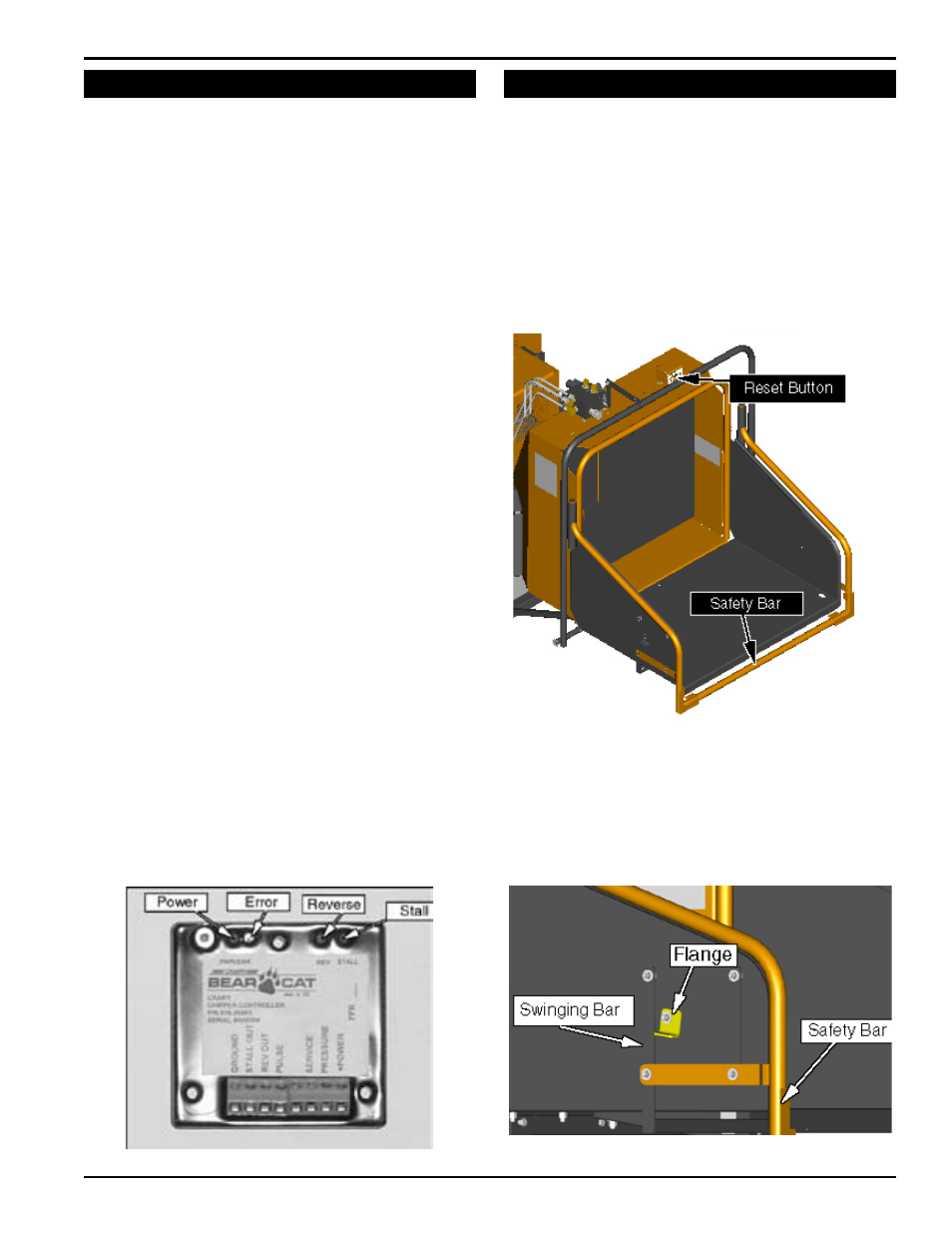

there is an orange safety bar located around the extension

tray that will stop the chipper when pushed in. When the

safety bar has been activated, a red light signals the reset

button should be pushed before the feed roller will function.

When you are ready to resume chipping, push the reset

button that is on top of the chipper chute.

If false trips occur from a limb, the reset button can be held

in to override the system. upon start up, safety bar light

will be on and will require the reset button to be pushed in

before the feed roller will operate.

to lock the safety bar into travel position, place the exten-

sion tray in an upright position. Pushing the safety bar down

will lock the safety bar. to unlock, lower the extension tray

and push in on the safety bar. This will release the flange

and allow the safety bar to move freely.

Flange lock

Safety bar and reset button

4.7 SafeTY bar oPeraTion