Pericolo – JLG X14JH Operator Manual User Manual

Page 75

4. Once the right tension is obtained, turn valve 1 clockwise and then tighten it. Clean any

grease leaks.

5. To stretch a track, put a grease gun inside grease nipple 2 and add grease until the track

deflection is within specifications.

There is something wrong if the track remains stretched once valve 1 has been turned anti‑

clockwise or loose after putting grease in grease nipple 2. In any case, never try to remove

tracks or dismantle the track tension cylinder, as the high pressure of the grease inside the

track is very dangerous.

4.3.3

CHECKING RUBBER TRACKS

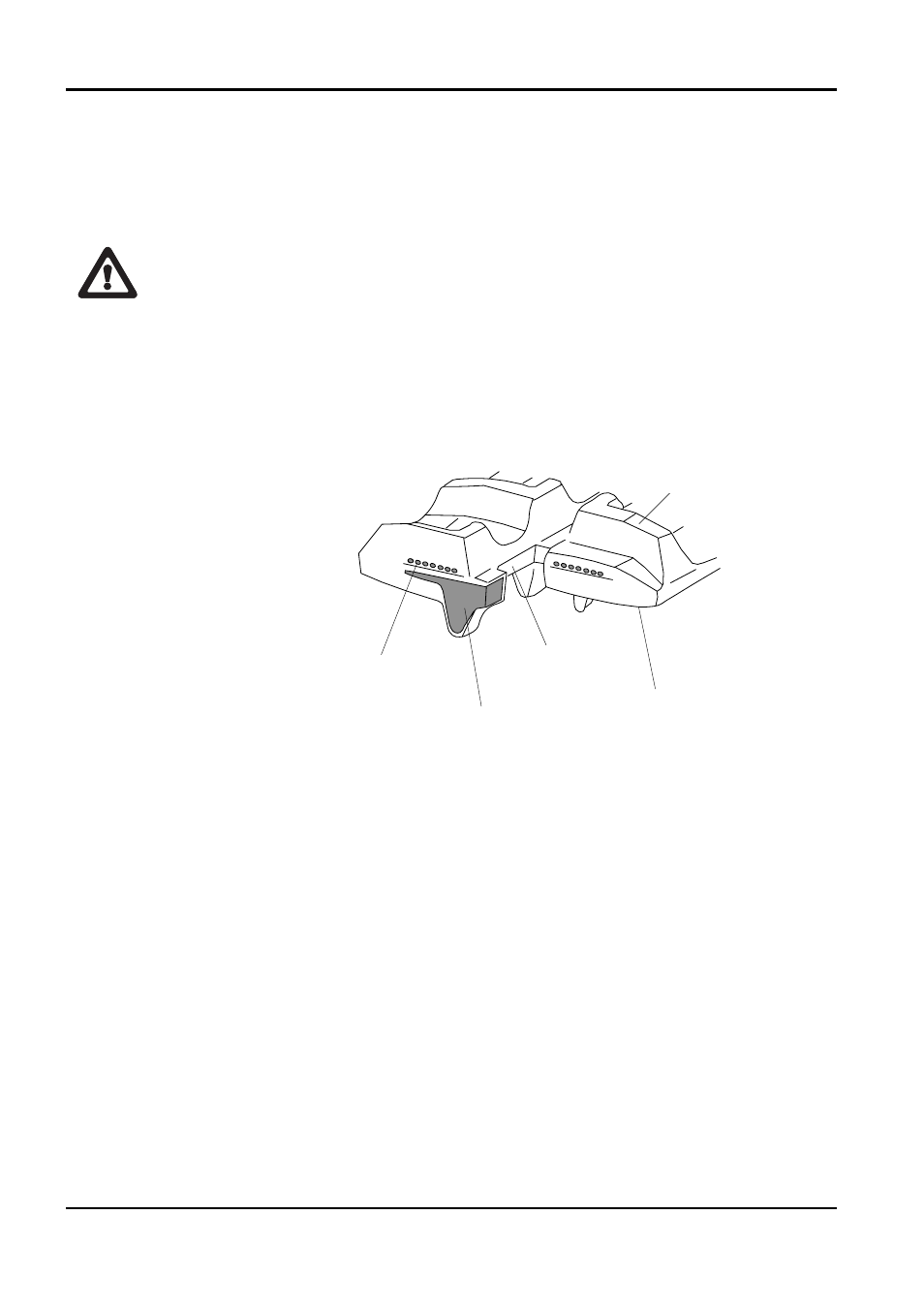

The rubber track structure is shown in fig.A. The steel ropes and the metal core are buried in

rubber.

The engraved threads are meant to give stability when moving on soft soil. They are situated

in the lower part of the ground support. The wheel guides, situated inside the track, prevent

the track from coming out of the guide rollers.

Causes of damages

A) Steel ropes breakage

An excessive tension causes the breaking of the steel ropes under the following conditions:

‑

When there is an excess of stones and foreign material between the track and the crawler

frame;

‑

When the track comes out of its guide;

‑

When there is strong friction like quick changes of direction.

BOOM LIFT MODELS X14JH

JLG

72

X14JHR0220311

Fig.

A

CORDE

D'ACCIAIO

SCUL

TURA

LA

TO RUOTA

FORO RUOT

A

DENTATA

ANIMA

METALLICA

PERICOLO

C

ARVED PROFILE

W

EEL SIDE

M

ETAL CORE

S

TEEL ROPES

S

PROCKET HOLE

DANGER