3 rubber track maintenance, Pericolo – JLG X14JH Operator Manual User Manual

Page 74

71

4.3 RUBBER TRACK MAINTENANCE

4.3.1

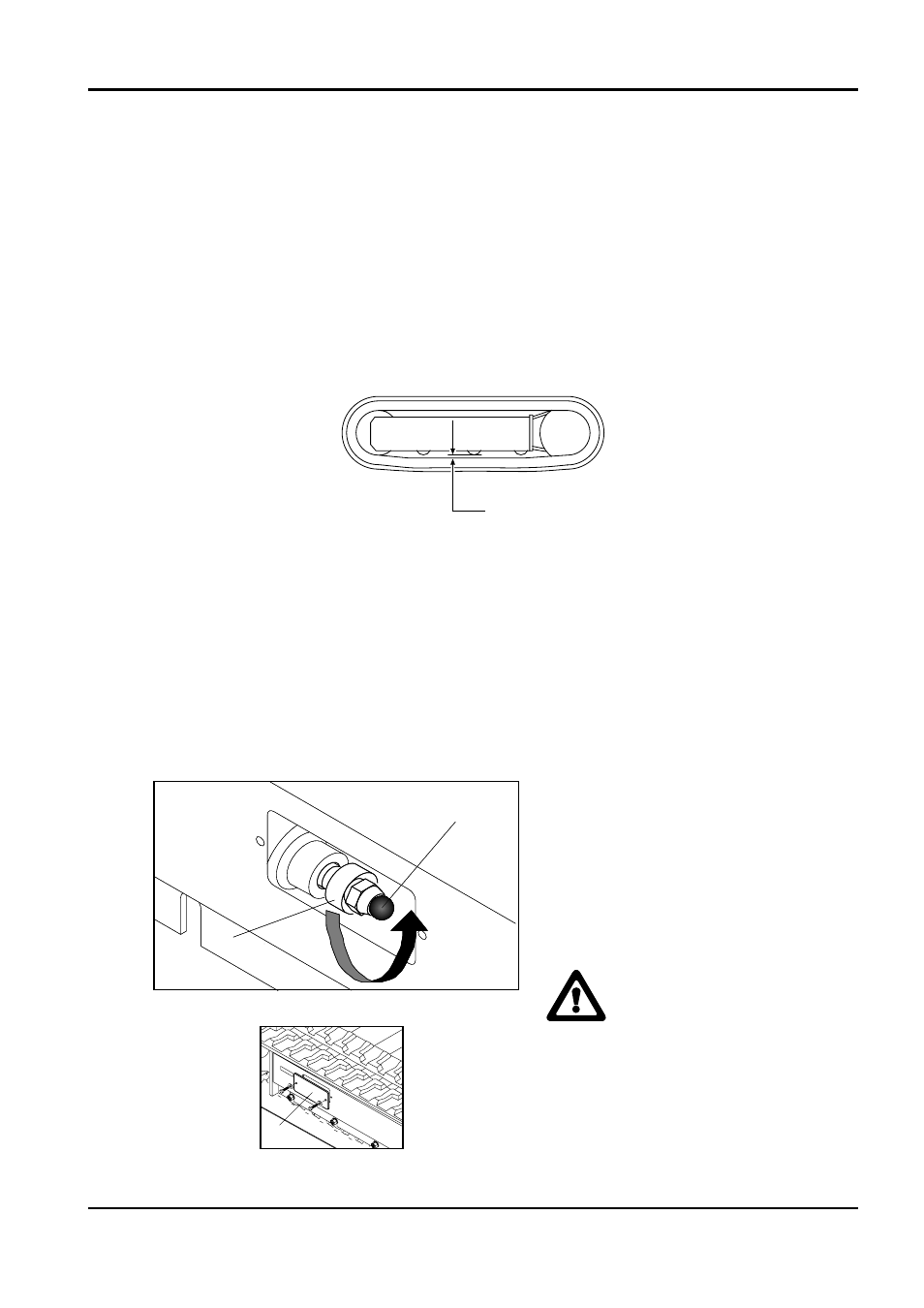

CHECKING TRACK TENSION

Park the machine on a solid and flat surface. Lift machine safety and put stable blocks under

the crawler frame to support it. Measure distance A from the roller bottom to the rubber

track rigid inner part. The track tension is correct if measurement A is between 10 and 15

mm.

If the track tension is not within the above‑mentioned measurements, not too loose nor too

tight, follow the instructions given in the following paragraph.

4.3.2

OPERATIONS TO LOOSEN OR TIGHTEN TRACK

The grease contained in the hydraulic track is under pressure. Therefore never loosen grea‑

sing valve 1 for more than one turn. If the valve is too loose, it might get expelled under the

grease pressure, exposing the operator to risk. Never loosen grease nipple 2.

Remove any mud or gravel jammed between the sprocket and the track links before loose‑

ning them.

1. Remove screws and plate 3 to have access to regulation.

2. To loosen track, slowly unscrew valve 1 anti clockwise for no more than one turn. One

turn of valve 1 is sufficient to loosen track.

3. If the grease does not start draining, make the track turn slowly.

BOOM LIFT MODELS X14JH

JLG

X14JHR0220311

A

5202

02B

H19

3

1

2

PERICOLO

DANGER