Walk-around inspection components, Walk-around inspection components -5, Daily walk-around inspection (sheet 1 of 2) -5 – JLG LiftPOD FS80 (1001070465) User Manual

Page 23: Figure 2-1. co

SECTION 2 - PREPARATION AND INSPECTION

LIFTPOD by JLG

1001070465

www.liftpod.com

2-5

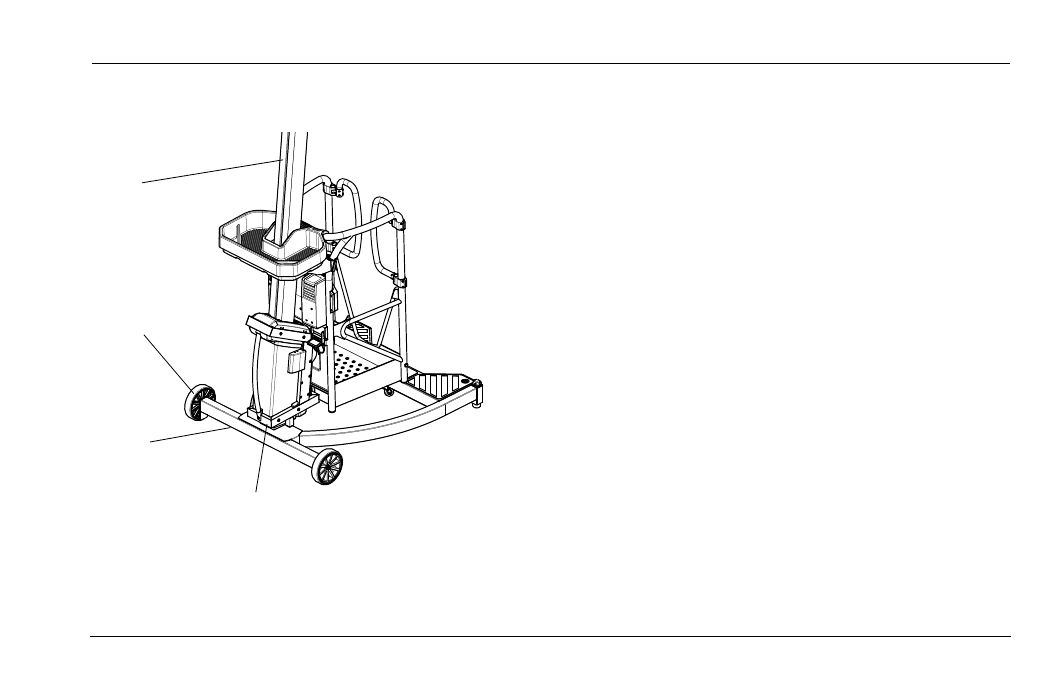

Walk-Around Inspection Components

NOTE:

On all components, make sure there are no loose or miss-

ing parts, everything is securely fastened, no visible dam-

age, or excessive wear exists in addition to any other

criteria mentioned.

1. Rear Wheels - Check for any debris stuck to or around

wheels. Make sure bolts are fastened. Make sure castor

locks operate properly (if equipped).

2. Base Frame - Check for cracks or corrosion, especially

around the mast-stump base (see Figure 2-2.). Check

level bubble is clean and secure.

3. Mast Assembly - No cracks or corrosion, especially

around base and flange; no excess wear, kinks, nicks or

damage; carriage running surfaces smooth and unob-

structed; free of dust, oil & grease.

4. Carriage Frame - check for visible cracks; check rollers

for visible wear; check carriage frame welds for visible

cracks (see Figure 2-2.).

5. Gearbox - check for any oil leaks, especially around

bottom shaft seal.

6. Swivel Castor Mechanism and Adjustable Feet -

Check for any debris stuck to or around wheels or

mechanism. Check adjustable feet for damage. Rubber

pads and tire must be in good order.

Figure 2-1. Daily Walk-Around Inspection

(Sheet 1 of 2)

1

2

3

4

REAR

FRONT

(FS80 base shown)