Maintenance, Aerovent im-977 3 – Aerovent IM-977 User Manual

Page 3

Aerovent IM-977

3

Maintenance

1. Before performing any maintenance on the fan, be

sure power is turned off and locked in the OFF

position at the service entrance.

2. Ventilators should be carefully checked at least once

a year. For critical or rugged applications, a routine

check every two or three months is suggested.

3. All motors supplied with Aerovent ventilators carry a

one-year warranty from date of shipment. For repairs

within the warranty period, the motor must be taken

to the motor manufacturer’s authorized service

dealer. Contact your representative for additional

warranty details.

4. A periodic motor check should consist of spinning

the motor shaft with the power off to be sure the

motor turns freely and the bearings run smoothly.

The belt on belt driven units should be removed

from the motor sheave.

5. When removing or installing a belt, do not force the

belt over the sheave. Loosen the motor mount so

that the belt can be easily slipped over the

sheave.

6. The belt on belt driven units should be removed and

carefully checked for glazing, cracks, ply separation

or irregular wear. A small irregularity in the contact

surface of the belt will result in noisy operation. If

any of these defects are apparent, the belt should

be replaced. Check the sheaves also for chipping,

dents or rough surfaces which could damage the

belt.

7. The correct belt tension is important. Too tight a

belt will result in excess bearing pressure on the

motor bearings and shaft pillow blocks and may

also overload the motor. Too loose a belt will result

in slippage which will quickly “burn” out belts. A

belt should feel “live” when thumped, approximately

1

⁄

4

" belt deflection (3 to 5 lb.) when subject to finger

pressure at midpoint between sheaves.

8. The belt alignment should also be checked to be

sure the belt is running perpendicularly to the rotat-

ing shafts. Motor and drive shafts must be parallel.

Improper alignment will result in excessive belt

wear.

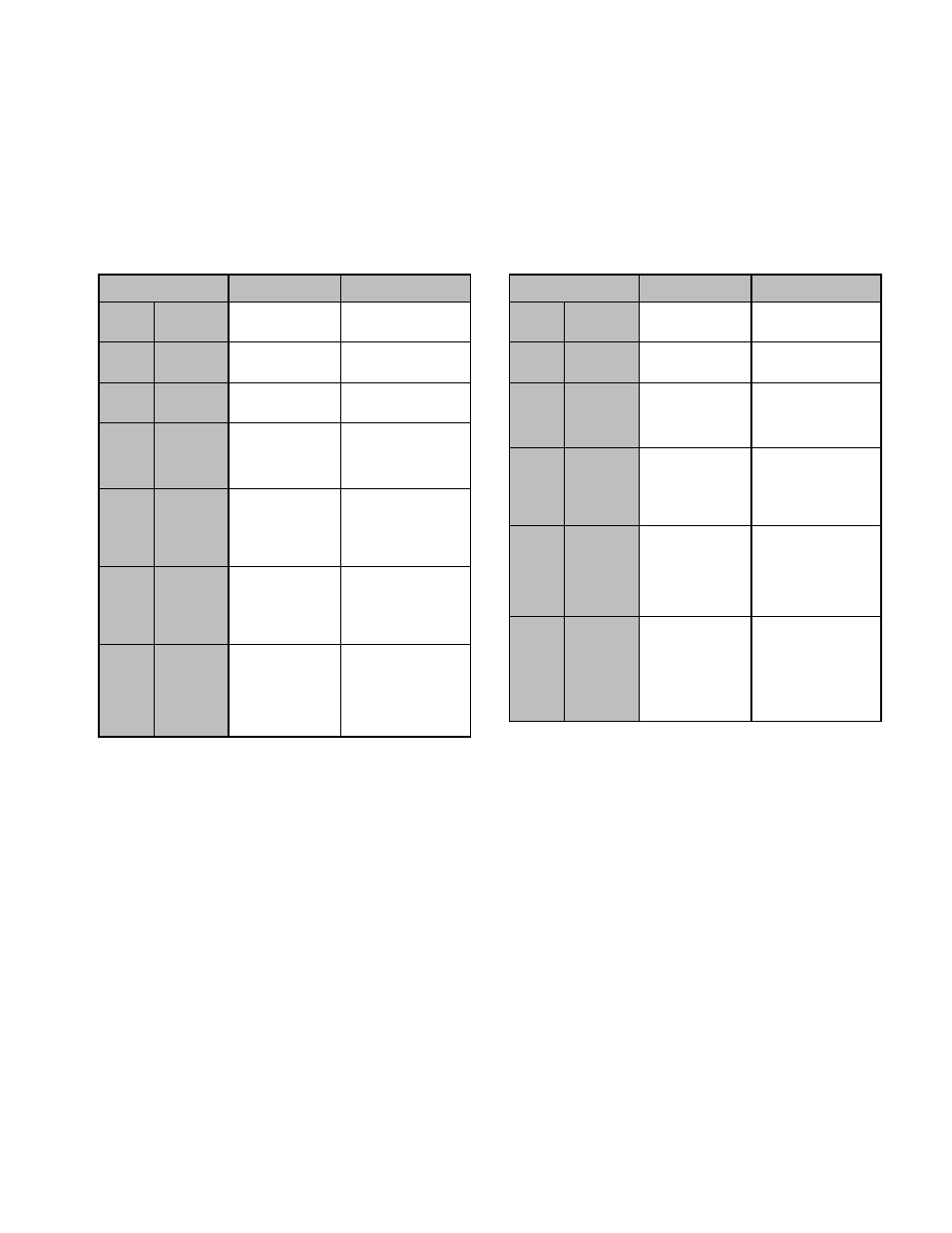

Table 2. Maximum Fan RPM (Belt Driven Units)

MODEL

MOTOR HP

MAXIMUM

FAN RPM

1B, 2B, 3B

1/4

1680

12AFA

4B

1/3

1465

5B

1/2

1675

1B, 2B, 3B

1/4

1470

14AFA

4B

1/3

1620

5B

1/2

1850

1B, 2B

1/4

905

18AFA

3B

1/3

995

4B

1/2

1140

1B, 2B

1/4

570

3B

1/3

625

24AFA

4B

1/2

720

5B

3/4

820

6B

1

905

1B

1/3

440

2B

1/2

500

3B

3/4

575

30AFA

4B

1

630

5B

1

1

⁄

2

725

6B

2

795

1B

1/2

370

2B

3/4

425

3B

1

465

36AFA

4B

1

1

⁄

2

535

5B

2

585

6B

3

670

1B

1/2

320

2B

3/4

370

3B

1

405

40AFA

4B

1

1

⁄

2

465

5B

2

510

6B

3

585

7B

5

690

MODEL

MOTOR HP

MAXIMUM

FAN RPM

1B, 2B, 3B

1/4

1420

14AWA

4B

1/3

1560

5B

1/2

1790

1B, 2B

1/4

900

18AWA

3B

1/3

990

4B

1/2

1135

1B, 2B

1/4

560

3B

1/3

615

24AWA

4B

1/2

705

5B

3/4

810

6B

1

890

1B

1/3

435

2B

1/2

500

3B

3/4

575

30AWA

4B

1

630

5B

1

1

⁄

2

720

6B

2

790

1B

1/2

365

2B

3/4

420

3B

1

460

36AWA

4B

1

1

⁄

2

525

5B

2

580

6B

3

660

7B

5

785

1B

1/2

315

2B

3/4

360

3B

1

395

40AWA

4B

1

1

⁄

2

450

5B

2

495

6B

3

570

7B

5

675

8B

7

1

⁄

2

765

WARNING: Especially check three-phase units for rotation.

For three-phase, rotation can be changed by interchang-

ing any two of the three line leads. If the unit is checked

on temporary wiring, it should be rechecked when per-

manently installed. Motor burn-out or tripped overload

protection devices are usually the result of wrong rota-

tion.

5. Electrical Input Check: Perform check of fan ampere

draw and verify that motor nameplate amps are not

exceeded. Take account of the service factor range if

motor is nameplated above a 1.0 service factor.

6. Fan RPM Check: Fan RPM should be checked and

verified with a tachometer. Refer to Table 2 for maxi-

mum fan RPM values.

The fan should not need balancing, as it was balanced

at the factory to be within stringent vibration levels

before shipment. However, there are several things that

may cause vibration such as rough handling in shipment

and erection, weak foundations and alignments.