Installation check, test and start procedure – Aerovent IM-977 User Manual

Page 2

2

Aerovent IM-977

Installation

Check, Test and Start Procedure

Roof ventilators should always be mounted to a flat,

level, solid and rigid structure. Particular caution should

be exercised when installing fans on metal buildings. Be

sure wall or roof is capable of supporting the fan(s).

Fans mounted on walls or roofs and not supported cor-

rectly will cause vibration that could cause damage or

injury.

Fans mounted off ground level should be rigidly mount-

ed to a structural platform and be placed over or as

near as possible to a solid wall or column.

Support for suspended fans must be cross-braced for

live load support to prevent side sway.

Use guy wires to help secure roof units if excessively

windy conditions prevail.

1. CAUTION! This fan contains rotating parts and

requires electrical service. Appropriate safety precau-

tions should be taken during installation, operation

and maintenance.

2. WARNING! Do not install or operate this fan in an

environment or atmosphere where combustible or

flammable materials, gases or fumes are present

unless it was specifically designed and manufac-

tured for use in that environment. Explosion or fire

can result. Explosive, corrosive, high temperature, or

other extreme conditions may require special con-

struction, inspection and maintenance. It is neces-

sary to observe the fan manufacturer’s recommen-

dations and limitations concerning the type of mate-

rial to be handled by the fan and its application to

special conditions.

3. When the roof ventilator is designed to be mounted

on a curb, the curb should be securely installed

prior to fan installation.

4. A damper, if used, should be securely mounted

within the curb or wall in a manner which allows

free and unobstructed operation.

5. CAUTION: All electrical work must be done in accor-

dance with local and/or national electrical codes as

applicable. If you are unfamiliar with methods of

installing electrical wiring, secure the services of a

qualified electrician.

6. WARNING: This product must be grounded.

7. DANGER! Make sure power is turned off and locked

in the OFF position at the service entrance before

installing, wiring or servicing the fan.

8. CAUTION! Before wiring the motor, check the supply

voltage against the motor nameplate voltage. High

or low voltage can damage the motor and void the

motor warranty. See Table 1.

9. On three-phase units check and calculate phase

unbalance as follows:

% Voltage Unbalance = 100 x max. voltage deviation

from avg. voltage ÷ avg. voltage

How To Use The Formula:

With voltages of 220, 216 and 213

a. Avg. Voltage = 220 + 216 + 213 = 649 ÷ 3 = 216

b. Max. Voltage Deviation From Avg. Voltage =

220 – 216 = 4

c. % Voltage Unbalance = 100 x (4 ÷ 216) = 1.8%

Voltage unbalance should not exceed 2%.

10. WARNING! Be sure to keep all wiring clear of rotat-

ing or moving parts.

11. WARNING! Before starting the fan, turn the wheel

to assure it rotates freely. If needed, adjust the

wheel/shaft/bearing/motor position as required to

achieve necessary clearances.

12. On belt driven units, assure belts are tensioned and

aligned properly. See Maintenance section.

13. Check all setscrews and keys. Tighten as necessary

prior to fan startup.

14. On roof units, anchor the fan securely to the curb.

Anchoring through the vertical portion of the curb

cap flange is recommended. Use a minimum of four

lag bolts or other suitable fasteners.

15. As with most installations of rotating machinery, due

to the nature of their applications, most fans are

available with protective guards and/or other devices

for required operating safety. Before operating the

unit in any of its applications, determine require-

ments for any guards and/or devices needed for

protection against accidental contact with moving

parts or against injury to nearby personnel or equip-

ment due to accidental rupture of fast moving

parts.

1. Disconnect power to this unit before servicing the

unit. Make sure power is turned off and locked in the

OFF position.

2. Tighten all bolts and setscrews securely and, on belt

driven fans, check sheave alignment and belt tension.

Tighten belts if necessary. NOTE THAT ALL BOLTS,

SETSCREWS AND BELTS SHOULD BE CHECKED

AND TIGHTENED AFTER TWO DAYS OF INITIAL

OPERATION.

3. Clearance should be checked all around between

wheel or propeller tips and the housing before start-

ing up. The wheel or propeller should not strike the

housing.

No initial lubrication is required. Motors and fan bear-

ings have been prelubricated by the motor manufac-

turer.

4. Apply power to the unit and check the rotation of the

wheel with the directional arrow on the unit.

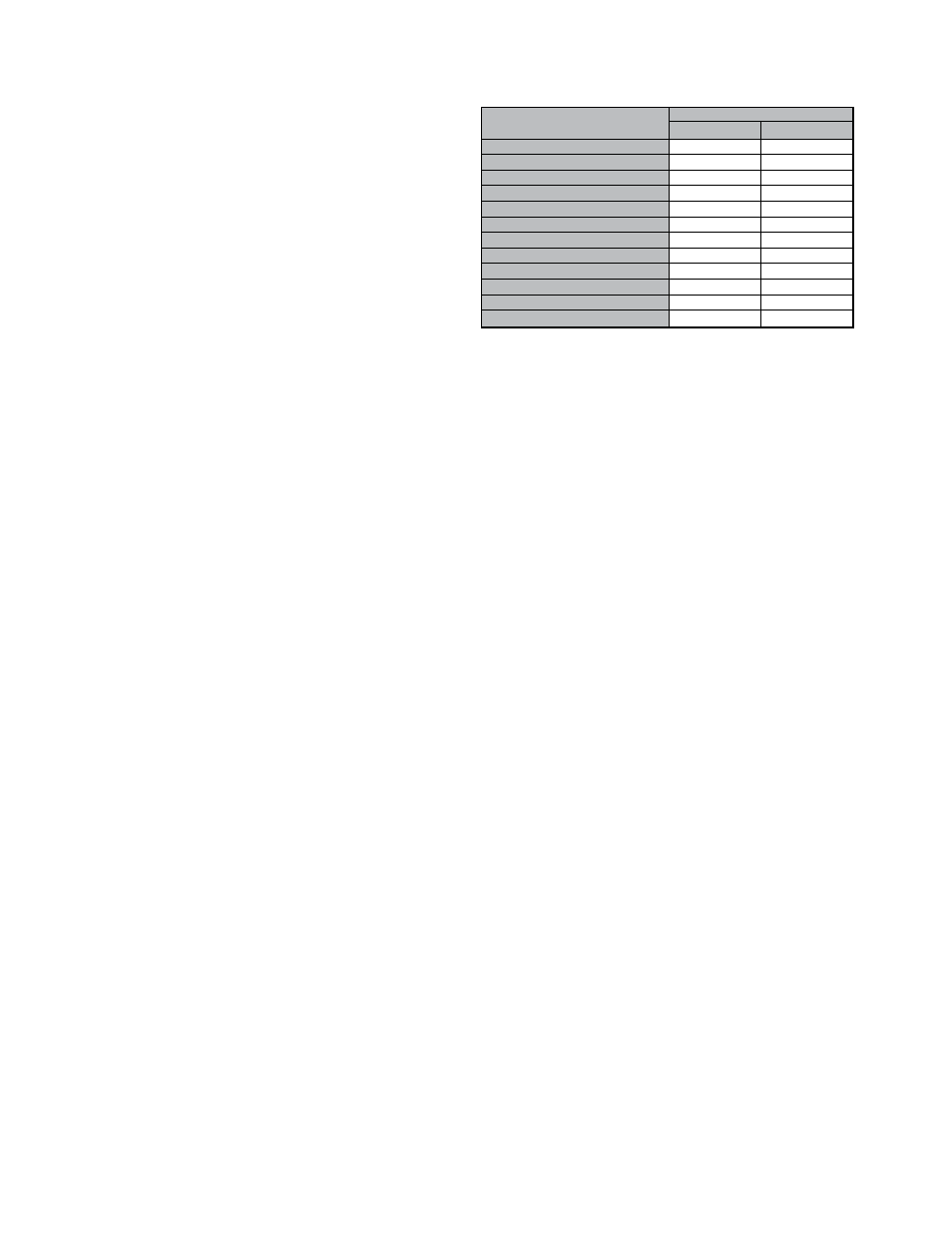

Table 1. Utilization Voltages

SYSTEM VOLTAGE/

UTILIZATION VOLTAGE

UNIT NAMEPLATE

MIN.

MAX.

115/60/1

104

127

208-230/60/1 or 208-230/60/3

187

253

230/60/1 or 230/60/3

207

253

277/60/1

249

305

200/60/3

180

220

380/60/3

342

418

460/60/3

414

506

575/60/3

517

633

110/50/1

99

121

220/50/1

198

242

380-415/50/3

342

456

440/50/3

396

484