Aerovent IM-301 User Manual

Page 4

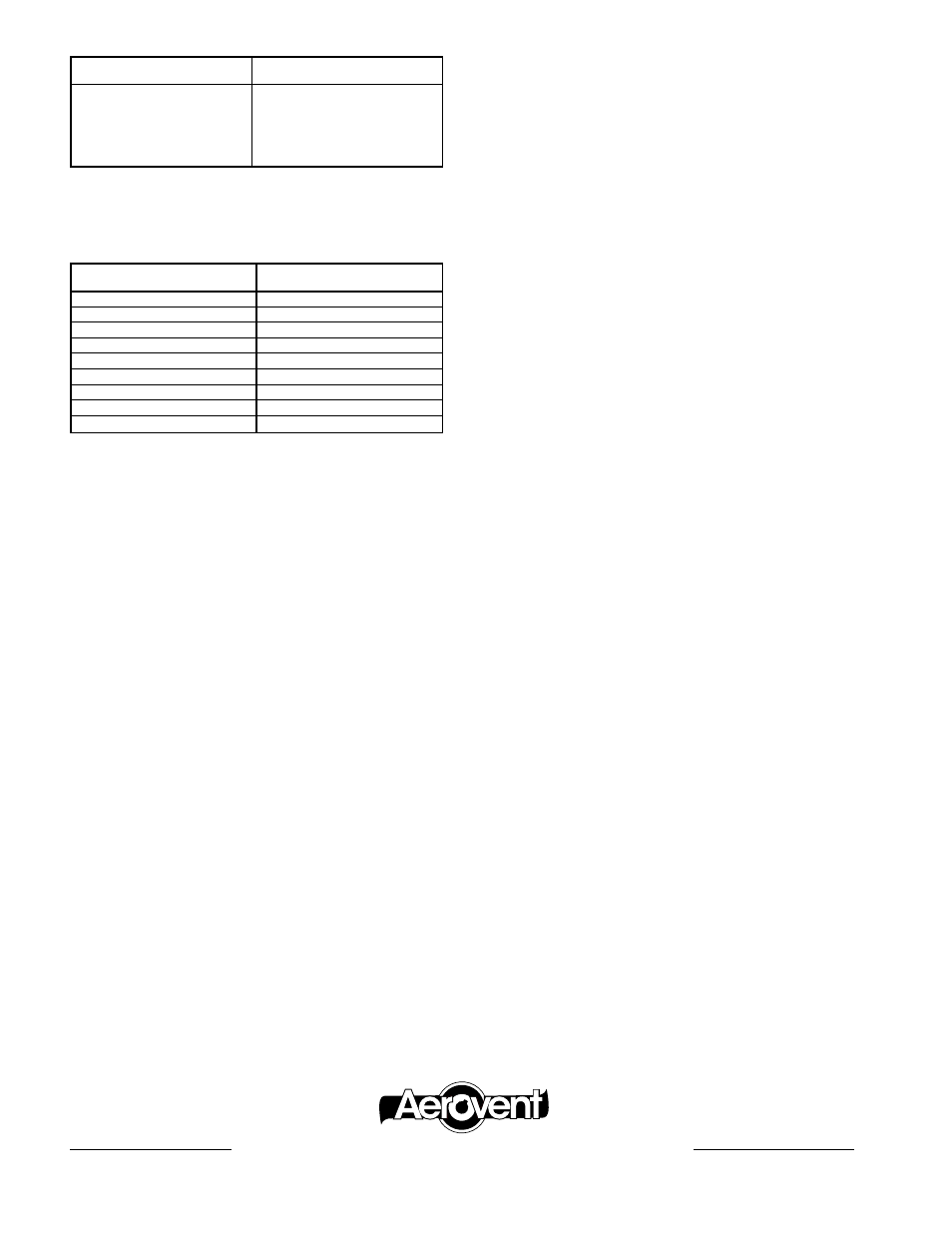

FAN SIZE

MINIMUM TIP

CLEARANCE (IN.)

056

.030

063

.030

071

.030

080

.030

090

.034

100

.038

112

.043

125

.049

140

.055

4.5 MINIMUM BLADE TIP CLEARANCE

The following dimension is the minimum clearance

between the tip of any blade in the fan case.

BOLT SIZE

TORQUE

FT-LBS

5

⁄

16

-18

13

3

⁄

16

-16

27.5

1

⁄

2

-13

75

5

⁄

8

-11

150

3

⁄

4

-10

240

7

⁄

8

-9

380

4.6 INSTRUCTIONS FOR LONG TERM STORAGE

4.6.1 If a fan is not installed immediately upon receipt, it is

the responsibility of the purchaser/user to see to it that

proper procedures are followed in order to minimize deterio-

ration which may result from idle storage.

4.6.2 Fan equipment should be stored indoors or in a well

sheltered location. The storage area must be clean and dry, well

above any maximum anticipated water level. The equipment

should be left crated/skidded, and not stacked over or under

other equipment. Unpainted machined parts should be given a

protective coating of Sprayon #322 or equal; this coating

should be renewed periodically per the manufacturer’s instruc-

tions. For fans equipped with vane sections, the core end cover

should be removed to gain adequate access to the interior and

reach the impeller hub. These interior areas require the same

rust inhibitor application and renewal as given above. The

cover should be replaced for storage, but each may be fastened

with a minimum of assembly hardware to facilitate access.

Remaining fastener hardware should be bagged and tagged,

and attached to the fan to prevent loss of these items. (It is

recommended that the fan be tagged indicating that all fasten-

ers must be replaced before operation.)

4.6.3 Each impeller blade should be numbered in sequence

with a felt-tipped marker. The blade marked No. 1 should be

rotated to top center. The blade number and date should be

recorded in a log book which is to be stored in a protective

pouch attached to the fan. During storage, the fan impeller

should be rotated by hand at least 10 revolutions every 30 days

to circulate the lubricant in the bearings in the motor. After the

tenth revolution, stop with a blade at top center which is not

the same one as is listed for the previous date in the log book.

4.6.4 If the fan motor is equipped with internal heaters, the

heaters must be energized throughout the storage period to

prevent condensation which might damage bearings or electri-

cal components. For motors not equipped with internal heat-

ers, the motor should be enclosed in heavy-duty polyethylene,

wrapped as tightly as possible.

Enclose bags of dessicant (such as Silicagel) with the

motor to minimize moisture problems. Check the dessicant

regularly and replace it periodically as dictated by climate

requirements. In addition, it is strongly suggested that the

motor manufacturer be contacted for specific long term stor-

age instructions.

4.6.5 The bearings in the fan motor or on the fan shaft

should require only minimum lubrication during storage.

Follow lubrication instructions in the instruction manual

enclosed with the fan.

4.6.6 After an extended period of storage, it is advisable to

have the fan motor thoroughly checked before the fan is

installed. Motor bearings, lubricant and electrical condition

should be given special consideration. Reassemble cover to fan

and follow AXIAD instruction manual for installation and

start-up.

AEROVENT | WWW.AEROVENT.COM

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7500 | Fax: 763-551-7501

®